Abstract

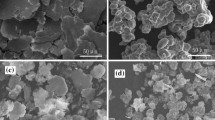

The rod milling method of cylindrical-shaped milling medium was applied to prepare the flaky carbonyl iron powders with varying milling times (10 h, 15 h and 20 h). The sample obtained by the spherical milling medium was also used as a contrast. The samples were characterized by x-ray diffraction, scanning electron microscopy and Raman spectroscopy, respectively. The complex permittivity and permeability were measured by vector network analyzer in the frequency range of 1–18 GHz. The results revealed that cylinder-prepared samples have better impedance matching properties and good absorbing properties. The minimum reflection loss (RL) of − 15.7 dB was observed at 6.0 GHz with a thickness of 1.5 mm, and the effective absorption frequency (RL < − 10 dB) ranged from 4.5 GHz to 8.5 GHz. This method is expected to play an important role for the promising design of flaky microwave absorbers, which can be applied to fifth-generation (5G) communication.

Similar content being viewed by others

References

L. Yan, J. Wang, X. Han, Y. Ren, Q. Liu, and F. Li, Nanotechnology 21, 095708 (2010).

N. Tian, C.Y. You, J. Liu, F. Qu, C.H. Wang, and Z.X. Lu, J. Magn. Magn. Mater. 339, 114 (2013).

Á. Kukovecz, T. Kanyó, Z. Kónya, and I. Kiricsi, Carbon 43, 994 (2005).

P. Baláž and E. Dutková, Miner. Eng. 22, 681 (2009).

L. Russo, F. Colangelo, R. Cioffi, I. Rea, and L.D. Stefano, Materials 4, 1023 (2011).

L. Takacs, Prog. Mater. Sci. 47, 355 (2002).

N.S. Lameck, K.K. Kiangi, and M.H. Moys, Miner. Eng. 19, 1357 (2006).

F.L. von Krüger, J.D. Donda, M.A.R. Drummond, and A.E.C. Peres, Dev. Miner. Process. 13, C4–86 (2000). https://doi.org/10.1016/S0167-4528(00)80031-9.

A.Z.M. Abouzeid and D.W. Fuerstenau, Int. J. Miner. Process. 102, 51 (2012).

M.D. Sinnott, P.W. Cleary, and R.D. Morrison, Miner. Eng. 24, 138 (2011).

P. Bhattacharya and C.K. Das, Ind. Eng. Chem. Res. 52, 9594 (2013).

Y. Kato, M. Horibe, M. Ameya, and S. Kurokawa, IEEE Trans. Instrum. Meas. 64, 1748 (2015).

H. Zhao, S.Y. Xu, D.M. Tang, Y. Yang, and B.S. Zhang, J. Appl. Phys. 116, 243911 (2014).

Y.C. Qing, W.C. Zhou, F. Luo, and D.M. Zhu, J. Magn. Magn. Mater. 323, 600 (2011).

J. Sandler, M. Shaffer, T. Prasse, W. Bauhofer, K. Schulte, and A.H. Windle, Polymer 40, 5967 (1999).

J. He, W. Wang, and J. Guan, J. Appl. Phys. 111, 093924 (2012).

F.S. Wen, W.L. Zuo, H.B. Yi, N. Wang, L. Qiao, and F.S. Li, Phys. B Condens. Matter 404, 3567 (2009).

J. Sun, H. Xu, Y. Shen, H. Bi, W. Liang, and R.B. Yang, J. Alloys Compd. 548, 18 (2013).

D. Graf, F. Molitor, K. Ensslin, C. Stampfer, A. Jungen, C. Hierold, and L. Wirtz, Nano Lett. 7, 238 (2007).

A. Naik, J. Zhou, C. Gao, G. Liu, and L. Wang, J. Energy Inst. 89, 21 (2016).

X. Weng, B. Li, Y. Zhang, X. Lv, and G. Gu, J. Alloys Compd. 695, 508 (2017).

A. Hajalilou, M. Hashim, M. Nahavandi, and I. Ismail, Adv. Powder Technol. 25, 423 (2014).

S.S. Kim, S.T. Kim, Y.C. Yoon, and K.S. Lee, J. Appl. Phys. 97, 10F905 (2005). https://doi.org/10.1063/1.1852371.

R.B. Yang and W.F. Liang, J. Appl. Phys. 109, 07A311 (2011). https://doi.org/10.1063/1.3536340.

Y.B. Feng, T. Qiu, C.Y. Shen, and X.Y. Li, IEEE Trans. Magn. 42, 363 (2006).

P.C. Ji, G.Z. Xie, N.Y. Xie, J. Li, J.W. Chen, R.Q. Xu, and J. Chen, J. Mater. Sci. Mater. Electron. 29, 4711 (2018).

S. Yoshida, S. Ando, Y. Shimada, and K. Suzuki, J. Appl. Phys. 93, 6659 (2003).

T. Maeda, S. Sugimoto, T. Kagotani, N. Tezuka, and K. Inomata, J. Magn. Magn. Mater. 281, 195 (2004).

L.J. Deng, P.H. Zhou, J.L. Xie, and L. Zhang, J. Appl. Phys. 101, 103916 (2007). https://doi.org/10.1063/1.2733610.

W. Liu, Q. Shao, G. Ji, X. Liang, Y. Cheng, B. Quan, and Y. Du, Chem. Eng. J. 313, 734 (2017).

F.S. Wen, L. Qiao, D. Zhou, W.L. Zuo, H.B. Yi, and F.S. Li, Chin. Phys. B 17, 2263 (2008).

M. Wu, Y.D. Zhang, S. Hui, T.D. Xiao, S.H. Ge, W.A. Hines, J.I. Budnick, and G.W. Taylor, Appl. Phys. Lett. 80, 4404 (2002).

X.F. Zhang, X.L. Dong, H. Huang, Y.Y. Liu, W.N. Wang, X.G. Zhu, B. Lv, J.P. Lei, and C.G. Lee, Appl. Phys. Lett. 89, 053115 (2006).

L. Qiao, F.S. Wen, J.Q. Wei, J.B. Wang, and F.S. Li, J. Appl. Phys. 103, 063903 (2008).

T. Kasagi, T. Tsutaoka, and K. Hatakeyama, IEEE Trans. Magn. 35, 3424 (2002).

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant No. 11304159); the Introduction of Talent Scientific Research Fund of Nanjing University of Posts and Telecommunications (Grant No. NY213016).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ji, P., Xie, G., Xie, N. et al. Microwave Absorbing Properties of Flaky Carbonyl Iron Powder Prepared by Rod Milling Method. J. Electron. Mater. 48, 2495–2500 (2019). https://doi.org/10.1007/s11664-019-06986-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-019-06986-1