Abstract

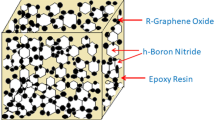

Three kinds of hybrid aluminum (Al) particles with binary particle size distribution, i.e., [2 μm/50 μm], [2 μm/18 μm] and [18 μm/50 μm], were added in epoxy (EP) to prepare hybrid Al/EP composites with enhanced dielectric properties and thermal conductivity for embedded capacitor applications. The dielectric permittivity, dissipation factor, and thermal conductivity of three types of hybrid Al/EP composites were investigated as a function of relative volume fraction of smaller-size Al of hybrid Al particles (V s) at a total filler content of 60 wt.%, respectively. The results indicate that dielectric permittivity and thermal conductivity of the hybrid Al/EP mainly depend on two factors, such as the type of hybrid filler and the V s. The maximum dielectric permittivity of 48 appears at V s = V 18μm/V (18μm+50μm) = 35%. While, the above two factors have a negligible influence on the dissipation factor, which is as low as 0.022. The highest thermal conductivity of 1.28 W/m K is obtained at V s = V 18μm/V (18μm+50μm) = 50%. The maximum thermal conductivity for three hybrid systems shifts towards lower V s with decreasing the size ratio of a larger Al to a smaller one.

Similar content being viewed by others

References

R. Popielarz and C.K. Chiang, Mater. Sci. Eng. 139, 48 (2007).

Z.M. Dang, Y.F. Yu, and H.P. Xu, Compos. Sci. Technol. 68, 171 (2008).

Y. Kobayashi, T. Tanase, and T. Tabata, J. Eur. Ceram. Soc. 28, 117 (2008).

J.W. Xu and C.P. Wong, Compos. A 38, 13 (2007).

S.S. Vaisakh, M. Hassanzadeh, and R. Metz, Polym. Adv. Technol. 25, 240 (2014).

Q. Zhang and S.H. Qi, J. Elastom. Plast. 47, 431 (2015).

C.L. Poh, M. Mariatti, and M.N. Ahmad, Fauzi. J. Mater. Sci. 25, 2111 (2014).

Z.J. Wang, W.Y. Zhou, and X.Z. Sui, J. Reinf. Plast. Compos. 34, 1126 (2015).

W.Y. Zhou D.M. Yu and C.F. Wang, Soc. Am. Mater. Process. Exhib. Long Beach 52, 18 (2008).

J.W. Bae, W. Kim, and S.H. Cho, J. Mater. Sci. 35, 5907 (2000).

W.Y. Zhou, Thermochim. Acta 512, 183 (2011).

W.Y. Zhou, S.H. Qi, and C.C. Tu, J. Appl. Polym. Sci. 140, 1312 (2007).

J.P. Hong, S.W. Yoon, and T. Hwang, Thermochim. Acta 537, 70 (2012).

W. Song, C.Q. Li, and L. Lin, Phys. Procedia 50, 405 (2013).

L.S. Wang, X.Y. Piao, and H. Zou, Appl. Phys. A 118, 243 (2015).

W.Y. Zhou, Q.G. Chen, and X.Z. Sui, Compos. A 71, 184 (2015).

Y.C. Zhou, H. Wang, and F. Xiang, Appl. Phys. Lett. 98, 182906 (2011).

W.Y. Zhou and D.M. Yu, J. Mater. Sci. 48, 7960 (2013).

W.Y. Zhou and J. Zuo, Polym. Mater. Sci. Eng. Sin. 27, 76 (2011).

H.R. Li, M. Jiang, and L.J. Dong, J. Macromol. Sci. B 52, 1073 (2013).

D.S. Saidina, M. Mariatti, and M.J. Julie, J. Mater. Sci. 25, 4923 (2014).

Z.J. Wang, W.Y. Zhou, X.Z. Sui, L.N. Dong, H.W. Cai, J. Zuo, and Q.G. Chen, J. Electron. Mater. 45, 3069 (2016).

K. Gaska, A. Rybak, and C. Kapusta, Polym. Adv. Technol. 26, 26 (2015).

B.L. Zhang, Q.Y. Zhang, H.P. Zhang, X.F. Lei, D.Z. Yin, X.L. Fan, and L.W. Zhou, J. Polym. Res. 19, 1 (2012).

D.J. Cumberland and R.J. Crawford, Handbook of Powder Technology: The Packing of Particles, vol. VI (Amsterdam: Elsevier, 1987) 33.

S. Choi and J. Kim, Compos. B 51, 140 (2013).

Acknowledgements

The authors gratefully acknowledge the financial supports from the National Science Foundation of China (51577154, 51073180), Shaanxi Provincial Natural Science Foundation of China (2016JM5014), the Scientific Research Program funded by Shaanxi Provincial Education Commission (14JK1485), the Key Laboratory of Engineering Dielectrics and Its Application, Ministry of Education, Harbin University of Science and Technology (JZK201301), and the Foundation for Key Program of Ministry of Education, China (212175).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sui, X., Zhou, W., Dong, L. et al. Epoxy Composites with Added Aluminum with Binary Particle Size Distribution for Enhanced Dielectric Properties and Thermal Conductivity. J. Electron. Mater. 45, 5974–5984 (2016). https://doi.org/10.1007/s11664-016-4834-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-016-4834-5