Abstract

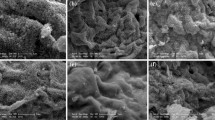

A series of Zn2+ doped Co–Cu ferrites with the formula Co0.5Cu0.5−x Zn x Fe2O4 (0.0 ≤ x ≤ 0.3) have been successfully synthesized using the solvothermal method. X-ray diffraction and scanning electron microscopy results indicate that a high-crystallized cubic Co0.5Cu0.5−x Zn x Fe2O4 with rod-like structure is obtained when the precursor is calcined at 800°C in air for 3 h. The lattice parameters increase with the increase of Zn2+ additional amount, attributed to the larger ionic radius of the substituted ion Zn2+ than Cu2+ ionic radius. Zn2+ substitution can improve the magnetic properties of Co0.5Cu0.5−x Zn x Fe2O4. Co0.5Cu0.4Zn0.1Fe2O4 obtained at 800°C has the highest specific saturation magnetization (73.7 ± 0.9 emu/g) and magnetic moment (3.13 ± 0.04 B.M.).

Similar content being viewed by others

References

P. Jadhav, K. Patankar, V. Mathe, N.L. Tarwal, J.H. Jang, and V. Puri, J. Magn. Magn. Mater. 385, 160 (2015).

K.W. Zhou, L.Q. Qin, X.H. Wu, W.W. Wu, Y.X. Shen, Y.L. Tian, and J.Y. Lu, Ceram. Int. 41, 1235 (2015).

Y. Yan, K.D.T. Ngo, D.B. Hou, M.K. Mu, Y.H. Mei, and G.Q. Lu, J. Electron. Mater. 44, 3788 (2015).

M. Javed Akhtar, J. Electron. Mater. 44, 2615 (2015).

Y. Zhou, W. Chen, Y.X. Shen, X.H. Wu, W.W. Wu, and J. Wu, J. Magn. Magn. Mater. 396, 198 (2015).

Y. Zhou, X.H. Wu, W.W. Wu, X.S. Huang, W. Chen, Y.L. Tian, and D. He, Mater. Sci. Semicond. Process. 41, 162–167 (2016).

R.S. Yadav, J. Havlica, M. Hnatko, P. Šajgalík, C. Alexander, M. Palou, E. Bartoníčková, M. Boháč, F. Frajkorová, J. Masilko, M. Zmrzlý, L. Kalina, M. Hajdúchová, and V. Enev, J. Magn. Magn. Mater. 378, 190 (2015).

L.Q. Qin, M.L. Gao, W.W. Wu, S.Q. Ou, K.T. Wang, B. Liu, and X.H. Wu, Ceram. Int. 40, 10857 (2014).

W. Wang, L. Zhuang, Y. Zhang, and H. Shen, Mater. Res. Bull. 69, 61 (2015).

H.Y. Zhu, R. Jiang, S.H. Huang, J. Yao, F.Q. Fu, and J.B. Li, Ceram. Int. 41, 11625 (2015).

H.X. Feng, B.Y. Chen, D.Y. Zhang, J.Q. Zhang, and L. Tan, J. Magn. Magn. Mater. 356, 68 (2014).

N. Adeela, K. Maaz, U. Khanc, S. Karim, A. Nisar, M. Ahmad, G. Ali, X.F. Han, J.L. Duan, and J. Liu, J. Alloys Compd. 639, 533 (2015).

L. Wang, B.K. Rai, and S.R. Mishra, Mater. Res. Bull. 65, 183 (2015).

D.Y. Lin, Y.K. Sun, Y. Xu, H.L. Gen, Q. Wu, and C. Yan, Ceram. Int. 41, 4581 (2015).

H.X. Feng, B.Y. Chen, D.Y. Zhang, J.Q. Zhang, and L. Tan, J. Magn. Magn. Mater. 356, 69 (2014).

T. Gaudisson, M. Artus, U. Acevedo, F. Herbst, S. Nowak, R. Valenzuela, and S. Ammar, J. Magn. Magn. Mater. 370, 87 (2014).

M. Stefanescu, M. Bozdog, C. Muntean, O. Stefanescu, and T. Vlase, J. Magn. Magn. Mater. 393, 92 (2015).

T. Slatineanu, A.R. Iordan, V. Oancea, M.N. Palamaru, I. Dumitru, C.P. Constantin, and O.F. Caltun, Mater. Sci. Eng. B 178, 1040 (2013).

M. Ben Ali, K. El Maalam, H. El Moussaoui, O. Mounkachi, M. Hamedoun, R. Masrour, E.K. Hlil, and A. Benyoussef, J. Magn. Magn. Mater. 398, 20 (2016).

M. Hashim, Alimuddin, S. Kumar, B.H. Koo, S.E. Shirsath, E.M. Mohammed, J. Shah, R.K. Kotnala, H.K. Choi, H. Chung, and J. Ravi Kumar, J. Alloys Compd. 518, 11 (2012).

B. Chandra Sekhar, G.S.N. Rao, O.F. Caltun, B. Dhana Lakshmi, B. Parvatheeswara Rao, and P.S.V. Subba Rao, J. Magn. Magn. Mater. 398, 59–63 (2016).

W. Chen, W.W. Wu, S.Q. Liu, J.W. Xu, D.S. Liu, X.H. Wu, Y. Zhou, and J. Wu, Mater. Sci. Semicond. Process. 39, 544 (2015).

D.M. Jnaneshwara, D.N. Avadhani, B. Daruka, B. Daruka, H. Prasad, B.M. Nagabhushana, S.C. Nagabhushana, S.C. Sharma, S.C. Prashantha, and C. Shivakumara, Spectrochim. Acta Part A 132, 256 (2014).

G.K. Williamson and W.H. Hall, Acta Metall. 1, 22 (1953).

S.K. Misra, S.I. Andronenko, S. Srinivasa Rao, J. Chess, and A. Punnoose, J. Magn. Magn. Mater. 394, 138 (2015).

X.H. Wu, W.W. Wu, L.Q. Qin, K.T. Wang, S.Q. Ou, K.W. Zhou, and Y.J. Fan, J. Magn. Magn. Mater. 379, 232 (2015).

X.H. Wu, J.H. Guo, M.J. McDonald, S.G. Li, B.B. Xu, and Y. Yang, Electrochim. Acta 163, 93 (2015).

X.H. Wu, W.W. Wu, K.W. Zhou, L.Q. Qin, S. Liao, and Y.J. Lin, J. Supercond. Nov. Magn. 27, 511 (2014).

I. Ahmada, T. Abbas, M.U. Islama, and A. Maqsood, Ceram. Int. 39, 6735 (2013).

S.M. Masoudpanah, S.A. Seyyed, M. Ebrahimi, M. Derakhshani, and S.M. Mirkazemi, J. Magn. Magn. Mater. 370, 122 (2014).

Z.A. Gilani, M.F. Warsi, M.N. Anjum, I. Shakir, S. Naseem, S. Riaz, and M.A. Khan, J. Alloys Compd. 639, 268 (2015).

W. Chen, Y. Zhou, J.Y. Lu, X.S. Huang, W.W. Wu, C.W. Lin, and Q. Wang, Ceram. Int. 42, 1114 (2016).

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China (Grant no. 21161002) and the Guangxi University Student Innovation Foundation of China (Grant No. SYJN20130356).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huang, X., Zhou, Y., Wu, W. et al. Effect of Zn2+ Substitution on the Structure and Magnetic Properties of Co0.5Cu0.5Fe2O4 Synthesized by Solvothermal Method. J. Electron. Mater. 45, 3113–3120 (2016). https://doi.org/10.1007/s11664-016-4400-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-016-4400-1