Abstract

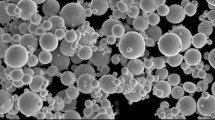

The Cu pillar is a thick underbump metallurgy (UBM) structure developed to alleviate current crowding in a flip-chip solder joint under operating conditions. We present in this work an examination of the electromigration reliability and morphologies of Cu pillar flip-chip solder joints formed by joining Ti/Cu/Ni UBM with largely elongated ∼62 μm Cu onto Cu substrate pad metallization using the Sn-3Ag-0.5Cu solder alloy. Three test conditions that controlled average current densities in solder joints and ambient temperatures were considered: 10 kA/cm2 at 150°C, 10 kA/cm2 at 160°C, and 15 kA/cm2 at 125°C. Electromigration reliability of this particular solder joint turns out to be greatly enhanced compared to a conventional solder joint with a thin-film-stack UBM. Cross-sectional examinations of solder joints upon failure indicate that cracks formed in (Cu,Ni)6Sn5 or Cu6Sn5 intermetallic compounds (IMCs) near the cathode side of the solder joint. Moreover, the ~52-μm-thick Sn-Ag-Cu solder after long-term current stressing has turned into a combination of ~80% Cu-Ni-Sn IMC and ~20% Sn-rich phases, which appeared in the form of large aggregates that in general were distributed on the cathode side of the solder joint.

Similar content being viewed by others

References

K.N. Tu, J. Appl. Phys. 94, 5451 (2003) doi:10.1063/1.1611263

T.Y. Lee, K.N. Tu, D.R. Frear, J. Appl. Phys. 90, 4502 (2001) doi:10.1063/1.1400096

L. Zhang, S. Ou, J. Huang, K.N. Tu, S. Gee, L. Nguyen, Appl. Phys. Lett. 89, 012106 (2006) doi:10.1063/1.2158702

L. Xu, J.H.L. Pang, K.N. Tu, Appl. Phys. Lett. 89, 221909 (2006), doi:10.1063/1.2397549

Y.-S. Lai, C.-W. Lee, C.-L. Kao, J. Electron Packag. 129, 56 (2007) doi:10.1115/1.2429710

Y.-S. Lai, K.-M. Chen, C.-L. Kao, C.-W. Lee, Y.-T. Chiu, Microelectron. Reliab. 47, 1273 (2007) doi:10.1016/j.microrel.2006.09.023

Y.-S. Lai and Y.-T. Chiu, J. Electron Packag. (in press)

K.N. Tu, C.C. Yeh, C.Y. Liu, C. Chen. Appl. Phys. Lett. 76, 988 (2000) doi:10.1063/1.125915

W.J. Choi, E.C.C. Yeh, K.N. Tu, J. Appl. Phys. 94, 5665 (2003) doi:10.1063/1.1616993

S.W. Liang, T.L. Shao, C. Chen, E.C.C. Yeh, K.N. Tu, J. Mater. Res. 21, 137 (2006) doi:10.1557/jmr.2006.0004

Y.-S. Lai, C.-L. Kao, Microelectron. Reliab. 46, 915 (2006) doi:10.1016/j.microrel.2005.02.007

Y.-S. Lai, C.-L. Kao, Microelectron. Reliab. 46, 1357 (2006) doi:10.1016/j.microrel.2005.08.009

J.-W. Nah, J.O. Suh, K.N. Tu, S.W. Yoon, V.S. Rao, V. Kripesh, et al., J. Appl. Phys. 100, 123513 (2006) doi:10.1063/1.2402475

S.K. Kang, W.K. Choi, D.-Y. Shih, D.W. Henderson, T. Gosselin, A. Sarkhel, et al., JOM 55, 61 (2003) doi:10.1007/s11837-003-0143-6

J.D. Wu, P.J. Zheng, C.W. Lee, S.C. Hung, J.J. Lee, Microelectron. Reliab. 46, 41 (2006) doi:10.1016/j.microrel.2005.01.012

Y.-S. Lai, C.-W. Lee, IEEE Trans. Compon. Packag. Tech. 30, 526 (2007) doi:10.1109/TCAPT.2007.898681

Y.-S. Lai, C.-L. Kao, J. Electron. Mater. 35, 972 (2006) doi:10.1007/BF02692556

C. Yu, J. Liu, H. Lu, P. Li, J. Chen, Intermetallics 15, 1471 (2007) doi:10.1016/j.intermet.2007.05.005

J. Chen, Y.-S. Lai, C.-Y. Ren, D.-J. Huang, Appl. Phys. Lett. 92, 081901 (2008) doi:10.1063/1.2884685

H. Sato, R.S. Toth, Phys. Rev. 124, 1833 (1961) doi:10.1103/PhysRev.124.1833

H. Sato, R.S. Toth, Phys. Rev. 127, 469 (1962) doi:10.1103/PhysRev.127.469

C.Y. Liu, J.T. Chen, Y.C. Chuang, L. Ke, S.J. Wang, Appl. Phys. Lett. 90, 112114 (2007) doi:10.1063/1.2714100

A.T. Huang, K.N. Tu, Y.-S. Lai, J. Appl. Phys. 100, 033512 (2006) doi:10.1063/1.2227621

C.M. Tsai, Y.L. Lin, J.Y. Tsai, Y.-S. Lai, C.R. Kao, J. Electron. Mater. 35, 1005 (2006) doi:10.1007/BF02692560

F.-Y. Ouyang, K.N. Tu, C.-L. Kao, Y.-S. Lai, Appl. Phys. Lett. 90, 211914 (2007) doi:10.1063/1.2743395

Acknowledgement

The authors are grateful to their colleagues, Yu-Hsiu Shao and Chiu-Wen Lee, for experimental support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lai, YS., Chiu, YT. & Chen, J. Electromigration Reliability and Morphologies of Cu Pillar Flip-Chip Solder Joints with Cu Substrate Pad Metallization. J. Electron. Mater. 37, 1624–1630 (2008). https://doi.org/10.1007/s11664-008-0515-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-008-0515-3