Abstract

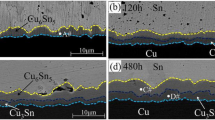

The interfacial reactions and growth kinetics of Sn–Ag–Cu were investigated during solid-state aging. The effects of chemical composition on the interface structure and the growth of interface under high temperature and high humidity were experimentally and numerically studied. Three solders Sn–0.4Ag–0.7Cu, Sn–0.7Ag–0.7Cu, and Sn–1.0Ag–0.7Cu were used to conduct several experiments. In order to determine the long-term reliability of the solder joints, thermally accelerated aging tests were performed for 0, 10, 30, 50, 100, and 350 h at 85 °C and 85% relative humidity. The surface morphology, thickness, and distribution of compounds were observed by scanning electron microscopy. The results showed that with increasing Ag content, the growth of Cu6Sn5 layer suppressed. The growth kinetics of intermetallic compound (IMC, Cu6Sn5 + Cu3Sn) remained a diffusion-controlled process during the isothermal aging, and Cu6Sn5 gradually transformed into a Cu3Sn IMC. The scallop-like shape disappeared at later aging stages, suggesting a change in the growth mechanism to the steady growth in the perpendicular direction to the interface. In addition, the results revealed that Ag effectively slowed the growth kinetics of Cu6Sn5. The apparent activation energy Q for Cu6Sn5 + Cu3Sn IMC of interfaces at Sn–0.4Ag–0.7Cu/Cu, Sn–0.7Ag–0.7Cu/Cu, and Sn–1.0Ag–0.7Cu/Cu was calculated to be 69.11, 88.90, and 56.61 kJ/mol, respectively.

Similar content being viewed by others

References

K.F. Gan, A.H.W. Ngan, The unusual size effect of eutectic Sn/Pb alloys in the micro regime: experiments and modeling. Acta Mater. 151, 282–292 (2018)

A. Zajączkowski, Thermodynamics of liquid Sn-Pb alloys determined by vapour pressure measurements. Calphad-comput. Coupl. Phase Diag. Thermochem. 60, 50–57 (2018)

T. Kaur, J. Sharma, T. Singh, Thickness optimization of Sn–Pb alloys for experimentally measuring mass attenuation coefficients. Nucl. Energy Technol. 3, 1–5 (2017)

M.A.R. Adawiyah, O.S. Azlina, Interfacial reaction between SAC305 lead–free solders and ENImAg surface finish and bare copper. Materialwiss. Werkstofftech. 48(3–4), 235–240 (2017)

W. Min, B. Lv, Prediction of phase formation in nanoscale Sn-Ag-Cu solder alloy. J. Electron. Mater. 45(1), 38–43 (2016)

N. Hort, Y. Huang, K. Kainer, Intermetallics in magnesium alloys. Adv. Eng. Mater. 8(4), 235–240 (2010)

A.J. Sunwoo, J.W. Morris, G.K. Lucey, The growth of Cu-Sn intermetallics at a pretinned copper-solder interface. Metall Trans A 23(4), 1323–1332 (1992)

A.T. Tan, A.W. Tan, F. Yusof, Effect of ultrasonic vibration time on the Cu/Sn-Ag-Cu/Cu joint soldered by low-power-high-frequency ultrasonic-assisted reflow soldering. Ultrason. Sonochem. 34, 616–625 (2017)

S.X. Chen, Effect of the addition of Zn and Ni no the properties of Cu6Sn5 intermetallic. Tianjin University 5 (2015)

F. Hodaj, A.M. Gusak, O. Liashenko, Possibility of a shape phase transition for solidification of tin at scallop-like surfaces of Cu6Sn5. Philos. Mag. Lett. 93(3), 166–173 (2013)

W.M. Liang, L.X. Bai, Applications of peakfit software in gamma-ray spectrum unscrambling measured by LaCl3 detector. Nucl Electron. Detect. Technol. 30, 835 (2010)

Z. Fan, Phil. Mag. A 73, 1663 (1996)

Y.L. Wang, K.K. Zhang, C.Y. Li et al., The morphology and evolution of Cu6Sn5 at the interface of Sn-2.5Ag-0.7Cu-0.1RE/Cu solder joint during the isothermal aging. Mater. Sci. Forum 704–705, 685–689 (2011)

F. Lin, B.I. Wenzhen, J.U. Guokui et al., Evolution of Ag3Sn at Sn-3.0Ag-0.3Cu-0.05Cr/Cu joint interfaces during thermal aging. J. Alloys Compd. 509(23), 6666–6672 (2011)

L. Meinshausen, H. Frémont, K. Weide-Zaage, Electro- and thermomigration induced Cu3Sn and Cu6Sn5 formation in SnAg3.0Cu0.5 bumps. Microelectron. Reliab. 55(1), 192 (2014)

H.J. Lee, J.S. Choi, J.K. Ha, Electrochemical behavior of Sn/Cu6Sn5/C composite prepared by using pulsed wire explosion in liquid medium for lithium-ion batteries. J. Nanosci. Nanotechnol. 18(9), 6455 (2018)

V.I. Dybkov, E.S. Meshkov, Kinetics of solution of iron-nickel alloys in liquid aluminum. Sov. Powder Metall. Met. Ceram. 31(11), 970–972 (1992)

M. Petrowsky, R. Frech, Temperature dependence of ion transport: the compensated Arrhenius equation. J. Phys. Chem. B 113(17), 5996–6000 (2009)

Q. Du, W.J. Poole, M.A. Wells, A mathematical model coupled to CALPHAD to predict precipitation kinetics for multicomponent aluminum alloys. Acta Mater. 60(9), 3830–3839 (2012)

H.L. Chen, H. Mao, Q. Chen, Database development and Calphad calculations for high entropy alloys: challenges, strategies, and tips. Mater. Chem. Phys. 210, 279 (2017)

Y. Peng, X. Li, X. Liang et al., Investigation of soldering process and interfacial microstructure evolution for the formation of full Cu3Sn joints in electronic packaging. Mater. Sci. Semicond. Process. 58, 39–50 (2017)

L. Meinshausen, H. Frémont, K. Weide-Zaage et al., Electro- and thermomigration induced Cu3Sn and Cu6Sn5 formation in SnAg3.0Cu0.5 bumps. Microelectron. Reliabil. 55(1), 192 (2014)

T.L. Yang, K.Y. Huang, S. Yang et al., Growth kinetics of Ag3Sn in silicon solar cells with a sintered Ag metallization layer. Sol. Energy Mater. Sol. Cells 123, 139–143 (2014)

C. Leinenbach, A. Lis et al., Early stage growth characteristics of Ag3Sn intermetallic compounds during solid-solid and solid-liquid reactions in the Ag-Sn interlayer system: experiments and simulations. J. Alloys Compd. 617, 763 (2014)

Acknowledgements

This study was supported by the National key research and development program (Grant Nos. 2017YFB0305700), Major science and technology special plan of Yunnan province, and Electronic paste with tin solder series product development (Grant No. 2018ZE004).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hailong, B., Zan, L., Junyu, C. et al. Influence of Ag content on the formation and growth of intermetallic compounds in Sn–Ag–Cu solder. J Mater Sci: Mater Electron 31, 10105–10112 (2020). https://doi.org/10.1007/s10854-020-03556-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-03556-8