Abstract

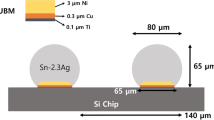

The structure of flip chip solder bumps was optimized in terms of shear height and shear speed using a shear test method with both experimental investigation and nonlinear, three-dimensional, finite element analysis being conducted. A representative, Pb-free solder composition, Sn-3.0Ag-0.5Cu, was used to optimize the shear test of the flip chip solder joints. Increasing the shear height, at a fixed shear speed, decreased the shear force, as did decreasing the shear speed, at a fixed shear height. These experimental and computational results supported the recommendation of low shear height and low shear speed condition for the shear testing of flip chip solder bumps. This optimized shear test method was applied to investigate the effect of various heights of mini bumps on the shear force of the solder joints. The shear force increased with increasing Ni-P mini bump height.

Similar content being viewed by others

References

K. Zeng, K.N. Tu, Mater. Sci. Eng. R 38, 55 (2002)

D.G. Kim, J.W. Kim, S.B. Jung, Mater. Sci. Eng., B 121, 204 (2005)

Y. Lin, W. Liu, Y. Guo, F.G. Shi, IEEE Trans. Adv. Packag. 28, 79 (2005)

D.S. Liu, C.Y. Ni, C.Y. Chen, Finite Elem. Anal. Des. 39, 661 (2003)

D.G. Yang, J.S. Liang, Q.Y. Li, L.J. Ernst, G.Q. Zhang, Microelectron. Reliab. 44, 1947 (2004)

J.W. Kim, S.B. Jung, Mater. Sci. Eng. A 371, 267 (2004)

J.W. Kim, S.B. Jung, Mater. Sci. Eng. A 397, 145 (2005)

S.W. Ricky Lee, X. Huang, Solder. Surf. Mt. Technol. 14, 45 (2002)

JESD22-B117, JEDEC Solid State Technology Association (USA), 2000

D.G. Kim, J.W. Kim, J.G. Lee, H. Mori, D.J. Quesnel, S.B. Jung, J. Alloy Compd. 395, 80 (2005)

M. He, W.H. Lau, G. Qi, Z. Chen, Thin Solid Films 462–463, 376 (2004)

J.W. Kim, D.G. Kim, S.B. Jung, Microelectron. Reliab. 46, 535 (2006)

H. Sakai, K. Nishimura, M. Motegi, and S. Sakuyama, Proc. 8th Symp. of Microjoining and Assembly Technology in Electronics (Yokohama: JWS, 2002) pp. 443–448

K.C. Chang, K.N. Chiang, IEEE Trans. Compon. Packag. Trans. 27, 373 (2004)

G.R. Johnson and W.H. Cook, Proc. 7th Int. Symp. on Ballistics (ADPA Hague, 1983), pp. 541–549

F.J. Zerilli, R.W. Armstrong, J. Appl. Phys. 61, 1816 (1987)

S.R. Bodner, Y.J. Partom, J. Appl. Mech. 42, 385 (1975)

P.S. Symmonds, Behaviour of Materials under Dynamic Loading (New York: ASME, 1965), pp. 106–124

ACKNOWLEDGEMENT

This work was supported by Grant No. RTI04-03-04 from the Regional Technology Innovation Program of the Ministry of Commerce, Industry and Energy (MOCIE).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, JW., Jung, SB. Design of Solder Joint Structure for Flip Chip Package with an Optimized Shear Test Method. J. Electron. Mater. 36, 690–696 (2007). https://doi.org/10.1007/s11664-007-0140-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-007-0140-6