Abstract

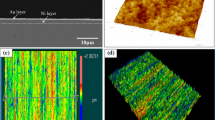

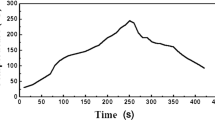

Nickel plating has been used as the under bump metallurgy (UBM) in the microelectronics industry. In this study, the electroplating process was demonstrated to be a good alternative approach to produce the Ni-P layer as UBM. The wettability of several commercial solder pastes, such as Sn-3.5Ag, Sn-37Pb, and Sn-3Ag-0.5Cu solder, on electroplated Ni-P with various phosphorous contents (7 wt.%, 10 wt.%, and 13 wt.%) was investigated. The role of phosphorus in the wettability was probed. The surface morphology and surface roughness in electroplated Ni-P was observed with the aid of both field emission scanning electron microscope (SEM) and atomic force microscope (AFM). The correlation between wettability and phosphorus contents in electroplated Ni-P was evaluated. As the phosphorous contents increased, the surface morphology of the Ni-P deposit was smoother and surface roughness of Ni-P became smaller. The improvement of surface morphology and surface roughness enhanced the wettability of electroplated Ni-P. The interfacial reaction between lead-free solder and electroplating Ni-P UBM was also investigated.

Similar content being viewed by others

References

J.H. Lau, Flip Chip Technologies (New York: McGraw-Hill, 1996), pp. 26–30.

D.S. Patterson, P. Eleniu, and J.A. Leal, Adv. Electron. Packaging 1, 337 (1997).

C.S. Chang, A. Oscilowski, and R.C. Bracken, IEEE Circuits Dev. Mag. 14, 45 (1998).

A.A. Liu, H.K. Kim, K.N. Tu, and P.A. Totta, J. Appl. Phys. 80, 2774 (1996).

H.K. Kim, K.N. Tu, and P.A. Totta, Appl. Phys. Lett. 68, 2204 (1996).

K.L. Lin and Y.C. Liu, 49th Electronic Components and Technology Conf. (ECTC) (Piscataway, NJ: IEEE, 1999), pp. 607–612.

B.L. Young and J.G. Duh, J. Electron. Mater. 30, 878 (2001).

C.S. Huang, J.H. Yeh, B.L. Young, and J.G. Duh, J. Electron. Mater. 31, 1230 (2002).

S.K. Kang, R.S. Rai, and S. Purrshothaman, J. Electron. Mater. 25, 1113 (1996).

J.W. Nah and K.W. Paik, IEEE Trans. Compon. Packaging Technol. 25, 32 (2002).

A. Brenner, G.E. Riddell, and J. Res, Nat. Bur. Standards 39, 35 (1947).

A. Brenner, Electrodeposition of Alloys: Principles and Practice (New York: Academic Press, 1963), pp. 457–483.

J.I. Goldstein, Scanning Electron Microscopy and X-ray Microanalysis (New York: Plenum Press, 1992), pp. 306–330.

R.L. Zeller III and U. Landau, J. Electrochem. Soc. 138, 1010 (1991); R.L. Zeller III and U. Landau, J. Electrochem. Soc. 139, 464 (1992).

T.M. Harris and Q.D. Dang, J. Electrochem. Soc. 140, 81 (1993).

T. Morikawa, T. Nakade, M. Yokoi, Y. Fukumoto, and C. Iwakura, Electrochim. Acta 42, 115 (1997).

B.L. Young, J.G. Duh, and B.S. Chiou, J. Electron. Mater. 30, 543 (2001).

P. Peeters, G.V.D. Hoorn, T. Daenen, A. Kurowski, and G. Staikov. Electrochim. Acta 47, 161 (2001).

Y.Y. Chen, J.G. Duh, and B.S. Chiou, J. Mater. Sci.: Mater. Electron. 11, 279 (2000).

B.D. Cullity and S.R. Stock, Elements of X-Ray Diffraction, 3rd ed. (Englewood Cliffs, NJ: Prentice-Hall, 2001), pp. 145–150.

http://www.yikst.com/Page/YIKSTE.html

S.T. Kao, Y.C. Lin, and J.G. Duh, J. Electron. Mater. (in press).

Y.C. Sohn and J. Yu, J. Mater. Res. 19, 2428 (2004).

S.W. Kim, J.W. Yoon, and S.B. Jeng, J. Electron. Mater. 33, 1182 (2004).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lin, YC., Duh, JG. & Chiou, BS. Wettability of electroplated Ni-P in under bump metallurgy with Sn-Ag-Cu solder. J. Electron. Mater. 35, 7–14 (2006). https://doi.org/10.1007/s11664-006-0177-y

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s11664-006-0177-y