Abstract

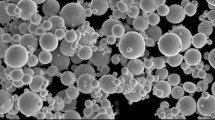

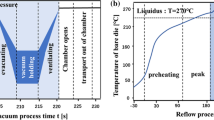

The microstructure of the flip-chip solder joints fabricated using stud bumps and Pb-free solder was characterized. The Au or Cu stud bumps formed on Al pads on Si die were aligned to corresponding metal pads in the substrate, which was printed with Sn-3.5Ag paste. Joints were fabricated by reflowing the solder paste. In the solder joints fabricated using Au stud bumps, Au-Sn intermetallics spread over the whole joints, and the solder remained randomly island-shaped. The δ-AuSn, ε-AuSn2, and η-AuSn4 intermetallic compounds formed sequentially from the Au stud bump. The microstructure of the solder joints did not change significantly even after multiple reflows. The AuSn4 was the main phase after reflow because of the fast dissolution of Au. In the solder joints fabricated using Cu stud bumps, the scallop-type Cu6Sn5 intermetallic was formed only at the Cu interface, and the solder was the main phase. The difference in the microstructure of the solder joints with Au and Cu stud bumps resulted from the dissolution-rate difference of Au and Cu into the solder.

Similar content being viewed by others

References

J.H. Lau and S.-W.R. Lee, Chip Scale Package (New York: McGraw-Hill, 1999), pp. 1–41.

J.H. Lau, Flip Chip Technologies (New York: McGraw-Hill, 1996), pp. 1–82.

K.N. Tu and K. Zeng, Mater. Sci. Eng. R 34, 1 (2001).

C.L. Wong and J. How, IEEE/CPMT Electronic Packaging Technology Conf. (New York: IEEE, 1997), pp. 244–250.

F. Ferrando, J.-F. Zeberli, P. Clot, and J.-M. Chenuz, Proc. of 4th Int. Conf. on Adhesive Joining and Coating Technology in Electronics Manufacturing (Piscataway, NJ: IEEE, 2000), pp. 205–211.

K. Tsunoi, T. Kusagaya, H. Kira, and J.H. Lau, Flip Chip Technologies (New York: McGraw-Hill, 1996), pp. 357–366.

W. Reinert and T. Harder, Proc. of 4th Int. Conf. on Adhesive Joining and Coating Technology in Electronics Manufacturing (Piscataway, NJ: IEEE, 2000), pp. 136–140.

S. Zama, D.F. Baldwin, and T. Hikami, IEEE Electronic Components and Technology Conf. (Piscataway, NJ: IEEE, 2000), pp. 1111–1117.

N.C. Lee, Proc. IMAPS (Molndal, Sweden: IMAPS Nordic, 2000), pp. 541–550.

K. Suganuma, Curr. Opin. Solid. State Mater. Sci. 5, 55 (2001).

D.R. Frear, W.B. Jones, and K.R. Kinsman, Solder Mechanics (Warrendale, PA: TMS, 1991), pp. 29–104 and 191–237.

M. Schaefer, R.A. Fournelle, and J. Liang, J. Electron. Mater. 27, 1167 (1998).

M. Klein, B. Wiens, M. Hutter, H. Oppermann, R. Aschenbrenner, and H. Reichl, IEEE Electronic Components and Technology Conf. (Piscataway, NJ: IEEE, 2000), pp. 40–45.

H. Okamoto and T.B. Massalski, Binary Alloy Phase Diagrams (Materials Park, OH: ASM, 1986), p. 315.

T.Y. Lee, W.J. Choi, and K.N. Tu, J. Mater. Res. 17, 291 (2002).

Y.-W. Yen and S.-W. Chen, J. Electron. Mater. 30, 1133 (2001).

M. Binnewies and E. Mike, Thermochemical Data of Elements and Compounds (New York: Wiley-VCH, 1999), p. 928.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Shin, MS., Kim, YH. Microstructure characterization of Sn-Ag solder joints between stud bumps and metal pads. J. Electron. Mater. 32, 1448–1454 (2003). https://doi.org/10.1007/s11664-003-0114-2

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s11664-003-0114-2