Abstract

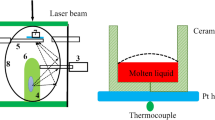

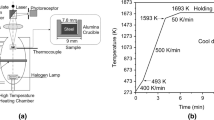

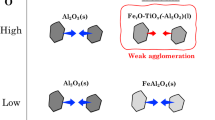

As we all know, the alumina inclusions on the surface of aluminum-killed molten steel are quickly attracted to form large clusters, but the alumina-magnesia complex inclusions disperse, where the interface characteristics between inclusions and molten steel play a crucial role in the agglomeration behavior on the surface of molten steel. In the present work, the effect of titanium and aluminum concentrations on the interface characteristics between molten steel and alumina inclusions is studied by using an improved sessile drop method. Then, the agglomeration behavior of alumina inclusions on the surface of molten steel is investigated by using a high-temperature laser microscope, and the attractive forces are discussed in detail from both the capillary force and viscous drag forces based on the interface characteristics between the inclusion and molten steel. The results show that the in situ observed attractive forces between the alumina inclusions on the surface of the molten steel are from 9.69 × 10−21 to 3.54 × 10−15 N, which reduce and increase, respectively, with the increase of titanium and aluminum concentration. It is agreeable to the calculated attractive force combining interface characteristics between inclusions and molten steel based on the concept of capillary force, which ranges from 1.94 × 10−21 to 3.76 × 10−16 N. Additionally, the attractive force decreases due to the viscous drag forces, which are approximately 2.43 × 10−21 to 3.11 × 10−18 N as the inclusion particles are close to each other.

Similar content being viewed by others

References

G. Martin, S.K. Yerra, Y. Bréchet, M. Véron, J. Mithieux, B. Chéhab, L. Delannay, and T. Pardoen: Acta Mater., 2012, vol. 60, pp. 4646–60.

Q. Shu, T. Alatarvas, V.V. Visuri, and T. Fabritius: Mater. Trans. B, 2021, vol. 52, pp. 1818–29.

C. Zhang, L. Gao, and L. Zhu: ISIJ Int., 2018, vol. 58, pp. 965–69.

Q. Sun, H.S. Di, J.C. Li, B.Q. Wu, and R.D.K. Misra: Mater. Sci. Eng. A, 2016, vol. 669, pp. 150–58.

N. Verma, P.C. Pistorius, R.J. Fruehan, M. Potter, M. Lind, and S. Story: Metall. Mater. Trans. B., 2011, vol. 42B, pp. 711–19.

C.W. Seo, S.H. Kim, S.K. Jo, M.O. Suk, and S.M. Byun: Metall. Mater. Trans. B., 2010, vol. 41B, pp. 790–97.

Y. Kang, B. Sahebkar, P.R. Scheller, K. Morita, and D. Sichen: Metall. Mater. Trans. B., 2011, vol. 42B, pp. 522–34.

G. Wang, Y. Xiao, C. Zhao, J. Li, and D. Shang: Metall. Mater. Trans. B., 2017, vol. 49B, pp. 1–9.

K. Sasai: ISIJ Int., 2015, vol. 54, pp. 2780–89.

K. Sasai: Tetsu-to-Hagane, 2016, vol. 102, pp. 187–95.

H. Duan, Y. Ren, B.G. Thomas, and L. Zhang: Metall. Mater. Trans. B., 2019, vol. 50B, pp. 36–41.

S. Kimura, K. Nakajima, and S. Mizoguchi: Metall. Mater. Trans. B., 2001, vol. 32B, pp. 79–85.

Y. Li, L. Wang, J. Li, S. Yang, C. Chen, and X. Li: ISIJ Int., 2020, vol. 61, pp. 753–62.

Y. Wang and C. Liu: Mater. Trans. B., 2022, vol. 53, pp. 2768–73.

L.C. Zhong, M. Zeze, and K. Mukai: Acta Metall. Sin., 2004, vol. 6, pp. 795–804.

J. Jeong, D. Park, and S. Shim: Metall. Mater. Trans. B., 2020, vol. 5B, pp. 690–96.

A. Karasangabo and C. Bernhard: J. Adhes. Sci. Technol., 2012, vol. 26, pp. 1141–56.

L. Zheng, A. Malfliet, P. Wollants, B. Blanpain, and M. Guo: Acta Mater., 2016, vol. 120, pp. 443–52.

T. Young: Philos. Trans. R. Soc. Lond., 1805, vol. 95, pp. 65–87.

B. Yildiz and V. Bashiry: J. Adhes., 2018, vol. 95, pp. 929–42.

J. Lee, Y. Kim, and J. Choe: AISTech 2013 Iron Steel Technol. Conf., 2013, vol. 1, pp. 1117–22

W. Yang, Y. Zhang, L.F. Zhang, H.J. Duan, and L. Wang: J. Iron Steel Res. Int., 2015, vol. 12, pp. 1069–77.

S. Basu, S.K. Choudhary, and N.U. Girase: ISIJ Int., 2004, vol. 44, pp. 1653–60.

P. Yuan, J. Zhang, D.Z. Liu, H.B. Li, and B. Chen: Iron Steel, 2018, vol. 53, pp. 24–30. (in Chinese).

G. Du, J. Li, Z.B. Wang, and C.B. Shi: Steel Res. Int., 2017, vol. 88, p. 9999.

P.A. Kralchevsky, V.N. Paunov, I.B. Ivanov, and K. Nagayama: J. Colloid. Interface Sci., 1992, vol. 151, pp. 79–94.

V.N. Paunov, P.A. Kralchevsky, N.D. Denkov, and K. Nagayama: J. Colloid Interface Sci., 1993, vol. 157, pp. 100–12.

D.Y.C. Chan, J.D. Henry, and L.R. White: J. Colloid. Interface Sci., 1981, vol. 79, pp. 410–18.

K. Washino, E.L. Chan, H. Midou, T. Tsuji, and T. Tanaka: Chem. Eng. Sci., 2017, vol. 174, pp. 365–73.

P.A.B. Kralchevsky and K. Nagayama: Langmuir, 1994, vol. 10, pp. 23–36.

B. Radoev, M. Nedyalkov, and V. Dyakovich: Langmuir, 1992, vol. 8, pp. 2962–65.

S. Maenosono, C.D. Dushkin, and Y. Yamaguchi: Colloid. Polym. Sci., 1999, vol. 277, pp. 993–96.

A. Dani, G. Keiser, M. Yeganeh, and C. Maldarelli: Langmuir, 2015, vol. 31, pp. 13290–13302.

J. Ally and A. Amirfazli: Colloid. Surface A, 2010, vol. 360, pp. 120–28.

Z. Qiu, A. Malfliet, B. Blanpain, and M. Guo: Metal. Mater. Trans. B., 2022, vol. 53B, pp. 1–17.

Acknowledgments

The financial support from the National Key Research and Development Program of China (No. 2021YFB3702401), the Hunan Scientific Technology Projects (No. 2020WK2003), and the National Science Foundation of China (No. 52130408) are greatly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Long, Q., Wang, W. & Gao, X. Effect of Al–Ti Concentration on the Alumina Inclusions Agglomeration Behavior on the Surface of Molten Steel. Metall Mater Trans B 54, 2552–2563 (2023). https://doi.org/10.1007/s11663-023-02856-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-023-02856-8