Abstract

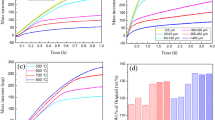

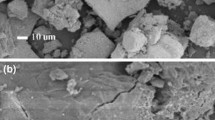

The environmental and economic recovery of rare-earth (RE) from NdFeB magnet waste is becoming increasingly important. In this study, the sulfurization possibility of two main RE-bearing phases of Nd2O3 and NdFeO3 in the fully oxidized NdFeB waste by ferric sulfate was evaluated. TG-DTA curves of the Nd2O3 and NdFeO3 sulfurization with 1.5 times of the theoretical Fe2(SO4)3·5H2O dosage showed that the temperatures range of Nd2(SO4)3 formation were 873 K to 963 K, and the starting temperature of Nd2(SO4)3 decomposition was ~ 1070 K. Specific experiments revealed by XRD and SEM-EDS analysis that Nd2O3 and NdFeO3 phases were successfully sulfated by Fe2(SO4)3·5H2O. The optimum roasting temperature was determined to be 973 K corresponding to the highest Nd leaching efficiency by the sulfurization of Nd2O3. At above 973 K, the decomposition of Nd2(SO4)3 resulted in the decrease of Nd leaching efficiency. Furthermore, the required roasting time and Fe2(SO4)3·5H2O dosage to obtain the same Nd leaching efficiency were different for the sulfurization of Nd2O3 and NdFeO3 at 973 K, and the sulfurization of NdFeO3 was more difficult than that of Nd2O3. Based on the results, an innovative method for recovering RE from NdFeB magnet waste was proposed.

Similar content being viewed by others

References

X.J Liu, T. Xu, Q. Hao, and J. G. Cui: Rare Met. Cemented Carb., 2014, vol. 42, pp. 48–53.

Y.Y Bian, S.Q. Guo, L. Jiang, K. Tang, and W.Z. Ding: J. Sustain. Metall., 2015, vol. 1, pp. 151–60.

J.P. Rabatho, W. Tongamp, Y. Takasaki, K. Haga, and A. Shibayama: J. Mater. Cycles Waste Manag., 2013, vol. 15, pp. 171–78.

Y.Y Bian, S.Q. Guo, Y.L. Y.L. Xu, K. Tang, X.G. Lu, and W.Z. Ding: Rare Met., 2015, vol. 34, pp. 1–6.

E.G. Polyakov, and A. S. Sibilev: Metallurgist, 2015, vol. 59, pp. 368–73.

H.W. Na, Y.H. Kim, H.T. Son, I.H. Jung, H.S. Choi, and T.B. Kim: Curr. Nanosc., 2014, vol. 10, pp. 128–30.

M. Itoh, K. Miura, K. Machida: J. Alloy Compd., 2009, vol. 477, pp. 484–87.

T. Uda: Mater. Trans., 2002, vol. 43, pp. 55–62.

M. Itoh, K. Miura, K. Machida: J. Alloy Compd., 2008, vol. 466, pp. 228–32.

J. Tang, C.F. Wei, D.W. Zhao, H. Lin, and G.H. Tian: Rare Met. Cemented Carb., 2009, vol. 37, pp. 9–11.

M.A.R. Önal, C.R. Borra, M.X. Guo, B. Blanpain, and T.V. Gerven: J. Rare Earths, 2017, vol. 35, pp. 574–84.

H.S Yoon, C.J Kim, K.W. Chung, S.J. Lee, A.R. Joe, Y.H. Shin, S.I. Lee, S.J. Yoo, and J.G. Kim: Korean J. Chem. Eng., 2014, vol. 31, pp. 706–11.

T.V. Hoogerstraete, B. Blanpain, T.V. Gerven, and K. Binnemans: RSC Adv., 2014, vol. 4, pp. 64099.

C.H. Lee, Y.J. Chen, C.H. Liao, S.R. Popuri, S.L. Tsai, and C.E. Hung: Metall. Mater. Trans. A, 2013, vol. 44, pp. 5825–33.

F.P. Liu, A. Porvali, J.L. Wang, H.Q. Wang, C. Peng, B.P. Wilson, and M. Lundström: Miner. Eng., 2020, vol. 145, pp. 106097.

M.A.R. Önal, C.R. Borra, M.X. Guo, B. Blanpain, and T.V. Gerven: J. Sustain. Metall., 2015, vol. 1, pp. 199–15.

J. Ponou, M. Garrouste, G. Dodbiba, T.Fujita, and J.W. Ahn: Sustainability, 2019, vol. 11, pp. 3461.

C.R. Borra, J. Mermans, B. Blanpain, Y. Pontikes, K. Binnemans, and T.V. Gerven: Miner. Eng., 2016, vol. 92, pp. 151–59.

C. Stanton: Sulfation roasting and leaching of samarium-cobalt magnet swarf for samarium recovery, master’s thesis, Colorado School of Mines, 2016.

K. Korkmaz, M. Alemrajabi, Å. Rasmuson, and K. Forsberg: J. Sustain. Metall., 2018, vol. 4, pp. 313–25.

M. Firdaus, M.A. Rhamdhani, W.J. Rankin, M. Pownceby, N.A.S. Webster, A.M. D’Angelo, and K. McGregor: Corros. Sci., 2018, vol. 133, pp. 374–85.

J.L. Wang, L.J. Wang, and F.P. Liu: Chin. J. Process Eng., 2020, vol. 20, pp. 921–28.

Y.J. Jiang, Y.C. Deng, W.B. Xin, and C. Guo: T. Indian I. Metals, 2020, vol. 73, pp. 703–11.

Acknowledgments

The authors gratefully acknowledge the financial support from the Program for Young Talents of Science and Technology in Universities of Inner Mongolia Autonomous Region (Grant No. NJYT-20-B27), and the Natural Science Foundation of Inner Mongolia (Grant Nos. 2020MS05009 and 2018LH05018).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted November 21, 2020; accepted April 9, 2021.

Rights and permissions

About this article

Cite this article

Xin, W., Deng, Y., Jiang, Y. et al. Sulfurization Roasting Process of Nd2O3 and Synthetic NdFeO3 with Ferric Sulfate. Metall Mater Trans B 52, 2151–2162 (2021). https://doi.org/10.1007/s11663-021-02178-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02178-7