Abstract

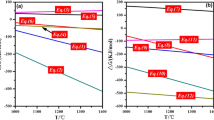

Due to the poor separability and low reducibility of fayalite in iron extracting from smelting waste slag, the composition of the original slag was modified for the nickel matte smelting process. Based on molecular dynamics simulation, thermodynamic calculation and experimental analyses, the influence mechanism of Fe/SiO2 ratio on physicochemical properties, Fe-containing phases and microstructure of the CaO-modified nickel matte smelting slag was investigated, to improve the FeO activity in the final slag and facilitate the subsequent iron extraction process. The results show that the SiO44− is the main form of silicon-oxygen anions in the FexO-SiO2-CaO-MgO-“NiO” slags. As the Fe/SiO2 ratio increased from 1.0 to 1.6, the fraction of SiO44− (Q0) in 15 wt pct CaO-modified nickel matte smelting slag are remarkably improved, and the degree of polymerization of silicate network is reduced correspondingly. Besides, the CaO-modified nickel slags with the Fe/SiO2 ratios of 1.2 to 1.4 present appropriate melting temperature, viscosity characteristics and interfacial tension between slag and matte. It indicates that the modified nickel slags are suitable candidates for nickel flash matte smelting. The concentration of Mg1−xFexO in 15 wt pct CaO-modified nickel slag is improved with increase of Fe/SiO2 ratio, which is conducive to the iron extraction from the smelting residues subsequently.

Similar content being viewed by others

References

J.X. Zhao, Z.Y. Zhao, Y.R. Cui, R.M. Shi, W.D. Tang, X.M. Li and N. Shang: Metallurgical Materials Transactions B, 2018, vol. 49, pp. 304-310.

J. Pan, G.L. Zheng, D.Q. Zhu and X.L. Zhou: Transactions of Nonferrous Metals Society of China, 2013, vol. 23, pp. 3421-3427.

S. Li, J. Pan, D.Q. Zhu, Z.Q. Guo, J.W. Xu and J.L. Chou: Powder Technology, 2019, vol. 347, pp. 159-169.

X.D. Xing, Z.G. Pang, C. Mo, S. Wang and J.T. Ju: Journal of Non-Crystalline Solids, 2020, vol. 530, pp. 9.

P. Piskunen, K. Avarmaa, H. Obrien, L. Klemettinen, H. Johto and P. Taskinen: Metall. Mater. Trans. B, 2018, vol. 49, pp. 98-112.

Y.Y. Shen, J.K. Chong, Z.N. Huang, J.K. Tian, W.J. Zhang, X.C. Tang, W.W. Ding and X.Y. Du: Materials, 2019, vol. 12, pp. 2562.

Y. Wang, R. Zhu, Q.Z. Chen, G.S. Wei, S.Y. Hu and Y.G. Guo: ISIJ international, 2018, vol. 58, pp. 2191

X. Li, B. Li, J. Deng, T. Lu, S. Wang, J. Li, D. Chen, Y. Liu and S. Wang: Industrial & Engineering Chemistry Research, 2014, vol. 53, pp. 11137-11144.

F.R. Huang, Y.L. Liao, J. Zhou, Y.Y. Wang and H. Li: Separation and Purification Technology, 2015, vol. 156, pp. 572-581.

Z.Q. Guo, D.Q. Zhu, J. Pan and F. Zhang: Minerals, 2017, vol. 7, pp. 98.

G.Z. Zhang, N. Wang, M. Chen and Y.Q. Cheng: ISIJ Int., 2019, vol. 60, pp. 602

X.M. Li, Z.Y. Wen, Y. Li, H.B. Yang and X.D. Xing: Transactions of Nonferrous Metals Society of China, 2019, vol. 29, pp. 2658-2666.

G.H. Wang, Y.R. Cui, X.M. Li, S.F. Yang, J.X. Zhao, H.L. Tang and X.T. Li: Minerals, 2020, vol. 10, pp. 149.

M. Chen, K. Avarmaa, L. Klemettinen, J. Shi, P. Taskinen and A. Jokilaakso: Metallurgical and Materials Transactions B, 2020, vol. 51, pp. 1552-1563.

H. Abdeyazdan, A. Fallah-Mehrjardi, T. Hidayat, M. Shevchenko, P.C. Hayes and E. Jak: Journal of Phase Equilibria and Diffusion, 2020, vol. 41, pp. 44-55.

M.Z. Zhao, J.W. Cao, Z. Wang and G.H. Li: Journal of Non-Crystalline Solids, 2019, vol. 513, pp. 144-151.

K. Ouyang, Z.H. Dou, T.A. Zhang, Y. Liu and L.P. Niu: Metallurgical Research & Technology, 2019, vol. 116, pp. 8.

L.S. Wu, C.J. Qi, B.J. Yan, J. Wang and Y.C. Dong: Metallurgical and Materials Transactions B, 2019, vol. 50, pp. 924-930.

F. Waanders and J. Nell: Hyperfine Interactions, 2013, vol. 218, pp. 101-105.

S.F. Zhang, X. Zhang, H.J. Peng, L.Y. Wen, G.B. Qiu, M.L. Hu and C.G. Bai: ISIJ international, 2014, vol. 54, pp. 734-742.

D. Liang, Z.M. Yan, X.W. Lv, J. Zhang and C.G. Bai: Metallurgical Materials Transactions B, 2017, vol. 48, pp. 573-581.

L.B. Deng, X.F. Zhang, M.X. Zhang and X.L. Jia: Journal of Non-Crystalline Solids, 2018, vol. 500, pp. 310-316.

X. Dai, J. Bai, D.T. Li, P. Yuan, T.G. Yan, L.X. Kong and W. Li: Journal of Fuel Chemistry and Technology, 2019, vol. 47, pp. 641-648.

C. Siakati, R. Macchieraldo, B. Kirchner, F. Tielens, A. Peys, D. Seveno and Y. Pontikes: Journal of Non-Crystalline Solids, 2020, vol. 528, pp. 119771.

G.H. Wang, Y.R. Cui, Z. Yang, Z.L. Guo, L. Zhao, X.M. Li, J.X. Zhao and W.D. Tang: J. Min. Metall. Sect. B Metall., 2020, p. 3.

X.F. Zhang, T. Jiang, X.X. Xue and B.S. Hu: Steel research international, 2016, vol. 87, pp. 87-94.

R.Z. Xu, J.L. Zhang, Z.Y. Wang and K.X. Jiao: Steel research international, 2017, vol. 88, pp. 1600241.

C. Feng, M.-S. Chu, J. Tang, J. Qin, F. Li and Z.-G. Liu: International Journal of Minerals, Metallurgy, and Materials, 2016, vol. 23, pp. 868-880.

L.B. Deng, R.D. Jia, F. Yun, X.F. Zhang, H. Li, M.X. Zhang, X.L. Jia, D. Ren and B.W. Li: Materials Chemistry and Physics, 2020, vol. 240, pp. 122212.

Z.B. Ma, X.Q. Tian, H.Q. Liao, Y.X. Guo and F.Q. Cheng: Journal of Cleaner Production, 2018, vol. 171, pp. 464-481.

Z.D. Pang, X.W. Lv, Z.M. Yan, D. Liang and J. Dang: Metallurgical and Materials Transactions B, 2019, vol. 50, pp. 385-394.

X.M. Li, Y. Li, X.Y. Zhang, Z.Y. Wen and X.D. Xing: Metallurgical and Materials Transactions B, 2020, vol. 51, pp. 925-936.

X.M. Li, H.B. Yang, J.B. Ruan, Y. Li, Z.Y. Wen and X.D. Xing: Journal of Iron and Steel Research International, 2020, vol. 27, pp. 1311-1321.

X. Xing, Z. Pang, C. Mo, S. Wang and J. Ju: Journal of Non-Crystalline Solids, 2020, vol. 530, pp. 119801.

J.H. Park: ISIJ international, 2012, vol. 52, pp. 1627-1636.

H. Portillo, M.C. Zuluaga, L.A. Ortega, A. Alonso-Olazabal, X. Murelaga and A. Martinez-Salcedo: Microchemical Journal, 2018, vol. 138, pp. 246-254.

W.W. Xuan, H.N. Wang and D.H. Xia: Fuel, 2019, vol. 242, pp. 362-367.

X.Z. Wang, L. Sun, X.L. Zhang, S.Z. Zhang, J.F. Wang and Y.Y.C. Zhang: Journal of Molecular Liquids, 2020, vol. 309, pp. 8.

C.H. Jiang, K. Li, J.L. Zhang, Q.H. Qin, Z.J. Liu, M.M. Sun, Z.M. Wang and W. Liang: Journal of Non-Crystalline Solids, 2018, vol. 502, pp. 76-82.

C.H. Jiang, H.X. Zhang, Z. Xiong, S. Chen, K. Li, J.L. Zhang, W. Liang, M.M. Sun, Z.M. Wang and L. Wang: J. Mol. Liquids, 2019, p. 112195.

W.-D. Tang, S.-T. Yang, G.-J. Cheng, Z.-X. Gao and X.-X. Xue: Steel Res. Int., 2018, vol. 89, pp. 1800226.

L. Yao, S. Ren, G.Q. Liu, Q.C. Liu, M. Kong and J. Yang: Metallurgical Research Technology, 2015, vol. 112, pp. 602.

J.H. Liu, G.H. Zhang and Z. Wang: Metallurgical and Materials Transactions B, 2017, vol. 48, pp. 3359-3363.

K. Hu, X.W. Lv, W.Z. Yu, Z.M. Yan, W. Lv and S.P. Li: Metallurgical and Materials Transactions B, 2019, vol. 50, pp. 2982-2992.

G.H. Zhang, W.W. Zheng and K.C. Chou: Metallurgical and Materials Transactions B, 2017, vol. 48, pp. 1134-1138.

J.H. Liu, G.H. Zhang, Y.D. Wu and K.C. Chou: Metallurgical and Materials Transactions B, 2016, vol. 47, pp. 798-803.

T.L. Li, C.G. Zhao, C.Y. Sun, S. Song and Q. Wang: Metallurgical and Materials Transactions B, 2020, vol. 51, pp. 2724-2734.

Z.D. Pang, X.W. Lv, Y.Y. Jiang, J.W. Ling and Z.M. Yan: Metallurgical and Materials Transactions B, 2020, vol. 51, pp. 722-731.

C.B. Shi, S.H. Shin, D.L. Zheng, J.W. Cho and J. Li: Metallurgical and Materials Transactions B, 2016, vol. 47, pp. 3343-3349.

R. Zhang, Y. Wang, X. Zhao, J.X. Jia, C.J. Liu and Y. Min: Metallurgical and Materials Transactions B, 2020, vol. 51, pp. 2021-2029.

Acknowledgment

The authors thank the National Natural Science Foundation of China (Nos. 51674186, 51774224) for the research support.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted September 15, 2020; accepted February 3, 2021.

Rights and permissions

About this article

Cite this article

Wang, G., Cui, Y., Yang, J. et al. Fe/SiO2 Ratio on the Properties, Microstructure and Fe-Containing Phases of Nickel Matte Smelting Slag. Metall Mater Trans B 52, 1463–1471 (2021). https://doi.org/10.1007/s11663-021-02113-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02113-w