Abstract

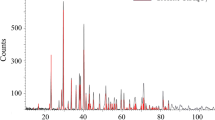

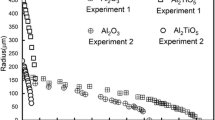

The current work investigates the dissolution path and mechanism of aluminum titanate inclusions in steelmaking slags using a high-temperature confocal scanning laser microscope (CSLM). To study this phenomenon, a single particle of aluminum titanate is dissolved in slag at 1773 K. During the dissolution process, gas bubble evolution is observed. Further, the particle–slag system is rapidly quenched using helium at different stages of dissolution. The quenched samples are examined for distribution of the constituent elements: Al, Ti, Ca, and Si using the scanning electron microscope (SEM). Phases such as alumina, titanium-rich slag, and calcium titanate are detected at the particle–slag interface. The dissolution path of aluminum titanate is proposed in the following steps. First, aluminum titanate dissociates into alumina, titanium oxide, and oxygen while slag penetrates through the particle. In the next step, the alumina and titanium oxide dissolve in slag, and the oxygen leaves the system. The existence of gas bubbles enhances the overall rate of Al2TiO5 dissolution. The dissolution of Al2TiO5 appears to be controlled by mass transfer in the slag. Evidence in support of this finding is the particle–slag interface characterization by line scan analysis and calculated diffusivity values being inversely proportional to the viscosity of slag.

Similar content being viewed by others

References

T. Liu, L. Chen, H. Bi, and X. Che: Acta Metall. Sin. 2014, vol. 27, pp. 452–6.

M. Vedani and A. Mannucci: ISIJ Int., 2008, vol. 42, pp. 1520–6.

M.B. Assar, J. Singleton (2005) AISTech, 2: 39–48.

Y. Zhang and M.S. Dudzic: J. Process Control, 2006, vol. 16, pp. 819–29.

S. Ogibayashi: Taikabutsu Overseas, 1994, vol. 15, pp. 3–14.

J. Burja, F. Tehovnik, J. Lamut, and M. Knap: Mater. Tehnol., 2013, vol. 47, pp. 217–22.

F. Tehovnik, J. Burja, B. Arh, and M. Knap: Metalurgija, 2015, vol. 54, pp. 371–4.

J.D. Smith, K.D. Peaslee: Development of Submerged Entry Nozzles That Resist Clogging. American Iron and Steele Institute, Washington, DC (2002).

S. Abdelaziz, G. Megahed, I. El-Mahallawi, and H. Ahmed: Ironmak. Steelmak., 2009, vol. 36, pp. 432–41.

S. Basu, S.K. Choudhary, and N.U. Girase: ISIJ Int., 2004, vol. 44, pp. 1653–60.

O. Araromi, B.G. Thomas, and E. Conzemius: Mater. Sci. Technol. Conf. 2009, pp. 1–10.

J.W. Farrell, and D.C. Hilty: in 28th Electric Furnace Proceedings, 1971, pp. 31–46.

B.G. Thomas and H. Bai: Iron Steel Soc., 2001, vol. 18, pp. 895–912.

P. Kaushik, R. Lule, G. Castillo, J.C. Delgado, F. Lopez, C. Perim, G. Pigatti, B. Henriques, F. Barbosa, and A. Nascimento: Iron Steel Technol., 2016, vol. 13, pp. 168–85.

H. Cui, Y.P. Bao, M. Wang, and W.S. Wu: Int. J. Miner. Metall. Mater., 2010, vol. 17, pp. 154–8.

A. Karasangabo and C. Bernhard: J. Adhes. Sci. Technol., 2012, vol. 26, pp. 1141–56.

D. Wang, J. Liu, M. Jiang, F. Tsukihashi, and H. Matsuura: Int. J. Miner. Metall. Mater., 2011, vol. 18, pp. 646–51.

Z.S. Ren, X.J. Hu, X.M. Hou, X.X. Xue, and K.C. Chou: Int. J. Miner. Metall. Mater., 2014, vol. 21, pp. 345–52.

M. Sharma, W. Mu, and N. Dogan: in AISTech 2018, 2018, pp. 2601–8.

M. Sharma, H.A. Dabkowska, and N. Dogan: Steel Res. Int., 2018; 70:1220-24

C.W. Bale, E. Bélisle, P. Chartrand, S.A. Decterov, G. Eriksson, A.E. Gheribi, K. Hack, I.-H. Jung, Y.-B. Kang, J. Melançon, A.D. Pelton, S. Petersen, C. Robelin, J. Sangster, P. Spencer, and M. Van Ende: Calphad, 2016, vol. 54, pp. 35–53.

B.J. Keene and K.C. Mills: Slag Atlas, Verlag Stahleisen, Dusseldorf, 1995, pp. 345-47.

K.C. Mills (1995) Slag atlas, Verlag Stahleisen, Dusseldorf, pp. 353-54.

J.F. Shackleford and W. Alexander: Materials Science and Engineering, 3rd edn., CRC Press, Boca Raton; 2001.

Microlink Measurement & Control: Technical Notes on Thermocouple Accuracy, http://www.microlink.co.uk/tctable.html.

Oishi Y, Cooper AR, Kingery WD (1965) J. Am. Ceram. Soc. 48:88–95.

J.H. Park, I. Jung, and H. Lee: ISIJ Int., 2006, vol. 46, pp. 1626–34.

H. jurgen Seifert and F. Aldinger: Zeitschrift für Met., 1996, vol. 87, pp. 841–53.

M. Serratos and A. Bronson: Wear, 1996, vol. 198, pp. 267–70.

I.B. De Arenas (2012) In: D.A. Lakshmanan (ed) Sintering of Ceramics—New Emerging Techniques, 1st Ed., InTech, Rijeka, pp. 503-36.

M. Sharma, W. Mu, and N. Dogan: JOM, 2018, vol. 70, pp. 1220–4.

M. Sharma and N. Dogan (2019) In: Nakano J, Pistorious PC, Tamerler C, Yasuda H, Zhang Z, Dogan N, Wang W, Saito N, Webler B (eds) Advanced Real Time Imaging II Cutting Edge Techniques in Materials Science Studies. Springer, New York, pp. 119–27.

O. Levenspiel: Chemical Reaction Engineering, vol. 19, Third., John Wiley and Sons, New york, 1999.

B.J. Monaghan and L. Chen: Ironmak. Steelmak., 2006, vol. 33, pp. 323–30.

O. Levenspiel: Chemical Reaction Engineering, 2nd Ed., John Wiley & Sons, New York, 1999.

M. Kowalski, P.J. Spencer, and D. Neuschutz: Slag Atlas, Verlag Stahleisen, Dusseldorf, 1995, pp. 21-214.

B.J. Monaghan and L. Chen: J. Non. Cryst. Solids, 2004, vol. 347, pp. 254–61.

B.J. Monaghan, S.A. Nightingale, L. Chen, and G.A. Brooks: in International Conference on Molten Slags Fluxes and Salts, South Africa, 2004, pp. 585–94.

Acknowledgments

The authors would like to acknowledge the support of the Natural Sciences and Engineering Research Council of Canada (NSERC, Project No. 20000514) for funding this research. This research used a high-temperature confocal laser scanning microscope—SVF17SP funded by Canada Foundation for Innovation John Evans Leaders Fund (CFI JELF, Project Number: 32826) and a scanning electron microscope—JEOL 6610 located at the Canadian Centre for Electron Microscopy at McMaster University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sharma, M., Dogan, N. Dissolution Behavior of Aluminum Titanate Inclusions in Steelmaking Slags. Metall Mater Trans B 51, 570–580 (2020). https://doi.org/10.1007/s11663-019-01762-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-019-01762-2