Abstract

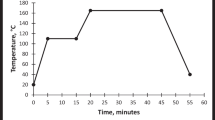

Selective HCl dissolution of ilmenite components for obtaining Ti or titanium dioxide (TiO2) has been highly recognized due to its advantages, greater environmental friendliness, and simplicity, compared to H2SO4 and Cl2 methods. The effect of numerous parameters has been studied with the one-factor-at-a-time method. The present study aimed to evaluate the effect of key operation parameters, such as acid-to-solid ratio (A/S: 5 to 20 mL/g), reaction temperature (T: 70 °C to 100 °C), and acid concentration (A pct: 15 to 30 wt pct), on the dissolution of Fe in HCl solution with the minimum Ti losses to the leachate from its abundant, domestic, and low-cost mineral source (Kahnooj ilmenite concentrate) using central composite design–response surface methodology. After 90 minutes of leaching, the Ti/Fe (pct) in terms of dissolved amounts was selected as the process assessment response function. Based on the conducted experimental and statistical analysis, increasing the levels of parameters in the studied domain leads to an increase in Ti/Fe (pct), in the order of A pct > T > A/S. Two statistically significant mutual interactions between A/S-T and T-A pct, with 95 pct confidence level, were revealed for the first time in this study. The optimization strategy was set to the minimization of Ti/Fe (pct) by considering the objective of study and the selected response function. The A/S, T, and A pct were determined to be 5 mL/g, 70 °C, and 15 pct, respectively, for maximum impurity dissolution and minimum Ti loss to the leachate.

Similar content being viewed by others

Notes

* DESIGN EXPERT* is a trademark of State-Ease Inc., Minneapolis, MN.

References

1. H. Salehi, H. Aghajani, and H. Salimkhani: Chem. Eng. Trans., 2018, vol. 66, pp. 397–402.

2. J.A. Ober: USGS (US Geological Survey), Reston, VA, 2018.

3. N. El-Hazek, T.A. Lasheen, R. El-Sheikh, and S.A. Zaki: Hydrometallurgy, 2007, vol. 87, pp. 45–50.

4. U. Diebold: Surf. Sci. Rep., 2003, vol. 48, pp. 53–229.

5. E. Quagliarini, F. Bondioli, G.B. Goffredo, A. Licciulli, and P. Munafò: J. Cult. Herit., 2012, vol. 13, pp. 204–09.

6. J. Kasanen, M. Suvanto, and T.T. Pakkanen: J. Appl. Polym. Sci., 2009, vol. 111, pp. 2597–2606.

7. M. Nikolova, A. Genov, S. Valkov, E. Yankov, D. Dechev, N. Ivanov, R. Bezdushnyi, and P. Petrov: J. Phys.: Conf. Ser., 2018, vol. 992, p. 012032.

8. N. Li, G. Liu, C. Zhen, F. Li, L. Zhang, and H.M. Cheng: Adv. Funct. Mater., 2011, vol. 21, pp. 1717–22.

9. J. Lademann, H.J. Weigmann, C. Rickmeyer, H. Barthelmes, H. Schaefer, G. Mueller, and W. Sterry: Skin Pharmacol. Physiol., 1999, vol. 12, pp. 247–56.

10. C. Wang, Q. Li, and R. D. Wang: Mater. Lett., 2004, vol. 58, pp. 1424–26.

11. N.K. Renuka, A.K. Praveen, and K.K. Aravindakshan: Mater. Lett., 2013, vol. 91, pp. 118–20.

12. T. Sreethawong, Y. Suzuki, and S. Yoshikawa: J. Solid State Chem., 2005, vol. 178, pp. 329–38.

13. T. Sugimoto and X. Zhou: J. Coll. Interface Sci., 2002, vol. 252, pp. 347–53.

14. E. Muniz, M. Góes, J. Silva, J.A. Varela, E. Joanni, R. Parra, and P.R. Bueno: Ceram. Int., 2011, vol. 37, pp. 1017–24.

15. T. Peng, D. Zhao, K. Dai, W. Shi, and K. Hirao: Phys. Chem., 2005, vol. 109, pp. 4947–52.

16. F. Wu, X. Li, Z. Wang, C. Xu, H. He, A. Qi, X. Yin, and H. Guo: Hydrometallurgy, 2013, vol. 140, pp. 82–88.

17. T. Tao, Q.-Y. Chen, H.-P. Hu, Z.-L. Yin, and Y. Chen: Trans. Nonferrous Met. Soc. China, 2012, vol. 22, pp. 1232–38.

18. A.R. Gharakhlou and M.N. Sarvi: Mater. Res. Express, 2017, vol. 4, p. 025027.

19. D. Aphairaj, T. Wirunmongkol, S. Pavasupree, and P. Limsuwan: Energy Procedia, 2011, vol. 9, pp. 539–44.

T.H. Nguyen and M.S. Lee: Miner. Process. Extract. Metall. Rev., 2018, pp. 1–17.

21. M.J. Gázquez, J.P. Bolívar, R. García-Tenorio, and F. Vaca: J. Hazard. Mater., 2009, vol. 166, pp. 1429–40.

22. X. Wang, C. Li, H. Yue, S. Yuan, C. Liu, S. Tang, and B. Liang: Chin. J. Chem. Eng., 2019, vol. 27, pp. 575–86.

F. Habashi, F. Kamaleddine, and E. Bourricaudy: Conf. Metall. Proc. COM 2014, Montreal, PQ, Canada, 2014.

24. C. Li, B. Liang, H. Song, J.-Q. Xu, and X.-Q. Wang: Micropor. Mesopor. Mater., 2008, vol. 115, pp. 293–300.

25. X. Xiong, Z. Wang, F. Wu, X. Li, and H. Guo: Adv. Powder Technol., 2013, vol. 24, pp. 60–67.

26. C. Li, B. Liang, L.H. Guo, and Z.B. Wu: Miner. Eng., 2006, vol. 19, pp. 1430–38.

S. Wahyuningsih, A. Ramelan, E. Pramono, P. Argawan, A. Djatisulistya, F. Firdiyono, E. Sulistiyono, and P. Sari: IOP Conf. Ser.: Mater. Sci. Eng., 2018, vol. 333, p. 012049.

28. J.H. Braun, A. Baidins, and R.E. Marganski: Progr. Organ. Coat., 1992, vol. 20, pp. 105–38.

29. H. Bordbar, A.A. Yousefi, and H. Abedini: Polyol. J., 2017, vol. 4, pp. 149–73.

30. S. Middlemas, Z.Z. Fang, and P. Fan: Hydrometallurgy, 2013, vol. 131, pp. 107–13.

31. W. Zhang, Z. Zhu, and C.Y. Cheng: Hydrometallurgy, 2011, vol. 108, pp. 177–88.

W.P. Duyvesteyn, B.J. Sabacky, D.E.V. Verhulst, P.G. West-Sells, T.M. Spitler, A. Vince, J.R. Burkholder, and B.J.P.M. Huls: U.S. Patent 6375923B1, Washington, DC.

G. McNulty: NORM V Int. Conf., Seville, Spain, IAEA, Wien, Austria, pp. 169–89.

M.J. Gázquez, J.P. Bolívar, R. Garcia-Tenorio, and F. Vaca: Mater. Sci. Appl., 2014, vol. 2014.

T. Hiraki, Y. Maruyama, Y. Suzuki, S. Itoh, and T. Nagasaka: Int. J. Miner. Metall. Mater., 2018, vol. 25, pp. 729–36.

36. C. McKinley and A. Ghahreman: Miner. Process. Extract. Metall., 2018, vol. 127, pp. 157–68.

37. B. Liang, C. Li, C. Zhang, and Y. Zhang: Hydrometallurgy, 2005, vol. 76, pp. 173–79.

S.A. Berkovich: U.S. Patent 3903239A.

39. M. Imahashi and N. Takamatsu: Bull. Chem. Soc. Jpn., 1976, vol. 49, pp. 1549–53.

40. E. Olanipekun: Hydrometallurgy, 1999, vol. 53, pp. 1–10.

41. L. Wei, H. Hu, Q. Chen, and J. Tan: Hydrometallurgy, 2009, vol. 99, pp. 39–44.

42. C. Sasikumar, D.S. Rao, S. Srikanth, N.K. Mukhopadhyay, and S.P. Mehrotra: Hydrometallurgy, 2007, vol. 88, pp. 154–69.

43. R. Vásquez and A. Molina: Miner. Eng., 2012, vol. 39, pp. 99–105.

44. N. Jabit and G. Senanayake: J. Phys.: Conf. Ser., 2018, vol. 1082, p. 012089.

45. F. Wu, X. Li, Z. Wang, L. Wu, H. Guo, X. Xiong, X. Zhang, and X. Wang: Int. J. Miner. Process., 2011, vol. 98, pp. 106–12.

46. J.P. van Dyk, N.M. Vegter, and P.C. Pistorius: Hydrometallurgy, 2002, vol. 65, pp. 31–36.

47. D. Chateigner: Combined Analysis, John Wiley & Sons, New York, NY, 2013, pp. 41–90.

48. E. Azimi, S. Karimipour, Z. Xu, J. Szymanski, and R. Gupta: Int. J. Coal Prepar. Utiliz., 2017, vol. 37, pp. 12–32.

49. B.N. Akhgar, M. Pazouki, M. Ranjbar, A. Hosseinnia, and R. Salarian: Chem. Eng. Res. Des., 2012, vol. 90, pp. 220–28.

50. N. Aslan: Powder Technol., 2008, vol. 185, pp. 80–86.

51. D.C. Montgomery: Design and Analysis of Experiments, John Wiley & Sons, Hoboken, NJ, 2017, pp. 328–404.

52. E. Azimi, S. Karimipour, M. Rahman, J. Szymanski, and R. Gupta: Energy Fuels, 2013, vol. 27, pp. 5595–5606.

53. S. Karimipour, R. Gerspacher, R. Gupta, and R. J. Spiteri: Fuel, 2013, vol. 103, pp. 308–20.

54. Z.R. Lazic: Design of Experiments in Chemical Engineering: a Practical Guide, John Wiley & Sons, New York, NY, 2006, pp. 262–367.

55. B. Oraon, G. Majumdar, and B. Ghosh: Mater. Design, 2006, vol. 27, pp. 1035–45.

56. N. Aslan: Powder Technology, 2007, vol. 174, pp. 127–33.

Stat-Ease version 7.0.0, Stat-Ease, Inc., Minneapolis, MN.

R. Sen: Int. Res. Process. Environ. Clean Technol., 1997, vol. 68, pp. 263–70.

59. R.G. Haverkamp, D. Kruger, and R. Rajashekar: Hydrometallurgy, 2016, vol. 163, pp. 198–203.

60. C. Li, B. Liang, and H. Wang: Hydrometallurgy, 2008, vol. 91, pp. 121–29.

61. T. Lasheen: Hydrometallurgy, 2005, vol. 76, pp. 123–29.

Acknowledgment

The authors acknowledge access to infrastructure from the Mining Engineering Department, Isfahan University of Technology.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted April 22, 2019.

Rights and permissions

About this article

Cite this article

Lavasani, S.H., Azimi, E. & Sarvi, M.N. The Dissolution of Fe in HCl from the Ilmenite Concentrate; Evaluating the Effect of Operating Parameters and Mutual Interactions. Metall Mater Trans B 50, 2586–2595 (2019). https://doi.org/10.1007/s11663-019-01704-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-019-01704-y