Abstract

The present study utilized zinc-tin nanoflowers (ZT-NFs) in a batch adsorption treatment process to effectively remove cadmium from synthetic wastewater. The batch adsorption strategy was optimized using the univariate approach to enhance the efficiency of the adsorption process. The dominant parameters examined in the optimization experiments were pH/volume of buffer solution, nanoflower amount, and sample agitation type/period. After determining the optimal batch adsorption conditions, equilibrium studies were performed by adding cadmium to synthetic wastewater at concentrations in the range of 1.0 – 40 mg/L. The quantification accuracy for cadmium was improved by developing the calibration plot with spiked sample matrix. The equilibrium data were subjected to mathematical modelling utilizing the Langmuir adsorption isotherm model. The calculated isotherm constants indicated a well-fitted isotherm model to the experimental data. The reported ZT-NFs-based adsorptive removal strategy was effectively employed to remove cadmium from synthetic wastewater.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Heavy metal toxicity is among the alarming issues facing humans, and these toxic metals are known to be more prevalent in areas where industrial activities are prominent (Yang et al., 2016). Cadmium, which is a toxic metal, occurs naturally in the environment but is released in larger proportions into living environs through many human activities such as the use of fossil fuels, untreated mining waste, welding, smelting, and cigarette smoking (Akkaya et al., 2017). Due to its poisonous effect on both animals and humans, this element has receives a lot of attention for its potential long-term risks to public health (Ehrampoush et al., 2015). Determining the level of cadmium in the environment is a crucial issue because of its potential toxicity to humans, plants, and other species, even at low concentrations (Ali et al., 2019). It is also one of the ten most harmful compounds for public health, according to the literature (Koju et al., 2018). It was reported that cadmium accumulation in the body can result in hypertension, bone ailments, and damage of the liver and kidneys (Dias et al., 2019). According to the World Health Organization, regions with the highest contamination levels recorded average daily consumption of cadmium in the range of 600 – 2000 µg/day, and regions with lower contamination levels- recorded cadmium levels in the range of 100 – 390 µg/day (WHO, 2011).

With reference to the negative impacts stated above, accurate and sensitive determination of cadmium is a very crucial issue. This metal has been determined in different matrices using a variety of analytical instruments including FAAS (flame atomic absorption spectrometry) (Prasad et al., 2006; Meira and Souza, 2017; Sixto et al., 2019; Fontes et al., 2020), GF-AAS (graphite furnace atomic absorption spectrometry) (Zeini Jahromi et al., 2007; Moinfar & Khayatian, 2017; Valasques et al., 2020), AFS (atomic fluorescence spectrometry) (Lei et al., 2018; Yuan et al., 2018), ICP-MS (inductively coupled plasma-mass spectrometry) (Rodríguez Giraldo et al., 2022; Shao et al., 2020; Zergui et al., 2022) and ICP-OES (inductively coupled plasma-optical emission spectrometry) (Guedes et al., 2020; Mohamed et al., 2020; Rodríguez Giraldo et al., 2022). Among these instruments, FAAS is reasonably affordable, easy to use, compatible with other equipment, and yields exact findings (Kasa et al., 2020).

According to the literature, adsorptive treatment strategies are commonly preferred for the removal of cadmium from various matrices (Baskaran & Abraham, 2022; Kavisri et al., 2023; Masood et al., 2023). In place of classical adsorbents, nanoadsorbents are capable of adsorbing a broad range of pollutants by reason of their unique properties such as adjustable pore sizes, elevated surface activities, intraparticle-diffusion distances, and extended sorption sites/surface areas (Homaeigohar, 2020; Yadav et al., 2020). An additional advantage associated with the utilization of nanoadsorbents is the feasibility of their functionalization, which allows them to possess a high level of selectivity towards different contaminants (Abbas et al., 2015, 2017; Cai et al., 2014, 2023; Harja et al., 2021; Lodhi et al., 2019). A wide range of novel nanomaterials such as nano volcanic ash (Alraddadi, 2022), nano-clay (Sethy et al., 2023), biofunctional reduced graphene oxide (Lin et al., 2023), nano-silica particles (Foroutan et al., 2020), Ca-doped Ni-Zn nanoferrites (Punia et al., 2022), and nano calcium carbonate doped chitin hydrogel (Dou et al., 2022) are commonly used as nanoadsorbents for the adsorption of cadmium from wastewater.

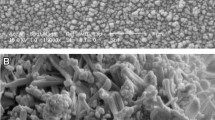

In this study, zinc-tin based nanoflower (ZT-NFs) were synthesized by a simple approach, characterized by SEM (scanning electron microscopy) and used for the adsorption of cadmium from synthetic wastewater. To the best of our knowledge, this is the first study where the ZT-NFs is used for effective removal of Cd from the water medium. All the dominant parameters of the batch adsorptive removal process were optimized in the univariate manner to determine the optimum conditions. The experimental data was modelled using the most widely used Langmuir adsorption isotherm.

2 Materials and Methods

2.1 Chemicals and Reagents

A commercially available Cd standard solution (1000 mg/L) in 2.0% HNO3 was purchased from Merck (Germany) and used for the optimization experiments. Synthesis of the ZT-NFs was achieved through the combination of zinc chloride, sodium hydroxide and tin (II) chloride. Tin (II) chloride and zinc chloride dihydrate were purchased from Merck, while sodium hydroxide was obtained from Sigma Aldrich (Germany). The standard and sample solutions were prepared with deionized water taken from an ELGA PureFlex III water treatment system. Analytical grade salts of potassium hydrogen phthalate and tris(hydroxymethyl)aminomethane were dissolved in deionized water to prepare buffer solutions that were adjusted to their specific pH values using dilute sodium hydroxide and hydrochloric acid solutions.

2.2 Instrumentations

An ATI UNICAM 929 AA (UK, Cambridge) model FAAS fitted with a D2 (deuterium) lamp for the correction of background noise was utilized for the determination of cadmium. The flame of the system was generated with a stoichiometric mixture of air (oxidant) and acetylene (fuel). A cadmium hollow cathode lamp, manufactured by Photron (Australia) was operated at 10 mA and used as radiation light source to detect cadmium at the analytical wavelength of 228.8 nm. The pH values of both the standard and sample solutions were regulated using a pH meter manufactured by Mettler Toledo (USA). The microwave-assisted hydrothermal synthesis procedure was conducted with a MILESTONE Start D digestion system (Sorisole, Italy). The drying and incubation procedures were conducted using a laboratory oven D-6450 Hanau model (Heraeus, Germany). A table top BIOBASE BKCTL5II centrifuge (Shandong, China) was employed for the purpose of separating the nanoflowers from solution.

2.3 Synthesis of the Zinc-tin Oxide Nanoflowers

The synthesis of the zinc-tin based nanoflowers (ZT-NFs) was achieved by modifying a method previously described in the literature (Jaculine et al., 2014). A total of 6.0 mmol of SnCl2.2H2O and 6.0 mmol of ZnCl2 were precisely weighed using an analytical balance and subsequently transferred into separate beakers. The two distinct solutions were prepared by adding 8.0 mL of deionized water. Approximately 4.0 mL of 5.0 M NaOH solution was pipetted into the SnCl2.2H2O solution and agitated using a magnetic stirrer for a duration of 10 min. Subsequently, the ZnCl2 solution was incrementally added to the mixture and further mixed for a period of 45 min. The nanoflowers was synthesized with a microwave digester employing a 55-min heating program as indicated in Fig. 1. Finally, the specimen was subjected to an overnight drying process in an oven maintained at a temperature of 50 °C.

2.4 Preparation of Synthetic Wastewater

Synthetic wastewater was prepared with the following composition via the procedure reported in the literature by Erşahin et al. (2014) (Ersahin et al., 2014). The chemicals used were CuCl2·2H2O (0.015 g/L), NiCl2·6H2O; boric acid; and ZnCl2 (0.025 g/L), (NH4)6Mo7O24·4H2O (0.045 g/L), Na2SeO3·5H2O (0.05 g/L), resazurin and MnCl2·4H2O (0.25 g/L), EDTA (0.5 g/L), CoCl2·6H2O and FeCl3·4H2O (1.0 g/L), and HCl 36% (0.5 mL) as micronutrients. Sunflower oil (1.4 mL), micronutrient (1.0 mL), MgSO4·7H2O (0.25 g/L), CaCl2.2H2O (0.37 g/L), NH4Cl (0.56 g/L), ovoalbumin (0.84 g/L), K2HPO4 (2.2 g/L), urea (3 g/L), NaCH3COOH·3H2O (6.3 g/L), starch (5.9 g/L), milk powder (5.6 g/L), and yeast extract (2.5 g/L) were used as macronutrients. Firstly, the synthetic wastewater was prepared as a concentrated stock solution and diluted with tap water until the chemical oxygen demand (COD) value of the wastewater reached 750 g/L. Then, it was diluted four times with ultrapure deionized water immediately before being used in the equilibrium adsorption experiments.

2.5 Procedure of the Batch Adsorptive Removal Process

In the batch adsorption experiments, falcon tubes with a capacity of 50 mL were filled with 35 mL of sample solution. Subsequently, 75 mg of ZT-NFs and 1.0 mL of a pH 6.0 buffer solution were added to the sample solution. The nanoflowers were uniformly dispersed within the aqueous solution with the aid of a mechanical shaker for a duration of 30 min. The nanoflowers were retrieved from the bottom of the falcon tube following a centrifugation period of 5.0 min at a speed of 3000 rpm. Then, 20 mL of the supernatant was transferred into a clean falcon tube and subjected to an additional centrifugation step. The final step of the procedure was transferring 2.0 mL of the effluent solution into a separate tube and aspirating into the FAAS system to measure absorbance signals.

The percent removal efficiency (%RE) of the ZT-NFs for cadmium was calculated according to Eq. 1.

In Eq. 1, Xi (mg/L) and Xe (mg/L) represent the initial and residual (equilibrium) adsorption levels, respectively. For the optimization experiments, the %REs were calculated via the difference in absorbance values of cadmium in the influent and effluent samples. On the other hand, the cadmium concentrations of the effluents calculated from the calibration plot of cadmium in synthetic wastewater were used as Xe values for the equilibrium modelling studies. All the experimental steps of the adsorptive removal process are shown in Fig. 2.

3 Results and Discussion

3.1 Characterization of the Zinc-tin Oxide Nanoflowers

The SEM images of the synthesized ZT-NFs are displayed in Fig. 3 with two different magnifications. The provided image displays a substantial cluster of nanoflowers that exhibit a discernible morphology reminiscent of rose petals. The images clearly demonstrate that each nanoflower consisted of multiple thin nanosheets, thereby offering a substantial surface area for its intended purpose.

3.2 Univariate Optimization of the Batch Adsorption Process

The batch adsorptive removal process was optimized univariately via pH/volume of buffer solution, nanoflower amount and agitation type/period. The standard solutions of cadmium used in all the optimization experiments were prepared with ultrapure water at room temperature. The effect of each parameter was evaluated according to the %RE calculated via the absorbance of the influent and effluent. The SDs (standard deviations) of the %REs were calculated for triplicate batch experiments. The optimum optimization parameters and values were selected as the highest means of triplicate %REs.

3.2.1 Effect of pH and Volume of Buffer Solution

The stability of an analyte on the surface of an adsorbent can be affected by the ionic balance of the sample solution. Therefore, the effect of pH on the adsorption process was examined by adding 3.0 mL of buffer solutions in the range of pH 5.0 – 8.0 (at 1.0 intervals) to 2.0 mg/L of cadmium standard solutions and treating with 25 mg ZT-NFs for 15 s and 1.0 min period of agitation by vortex and ultrasonication, respectively. As shown in Fig. 4, cadmium was adsorbed effectively onto the ZT-NFs in the aqueous media buffered at pH 6.0. Highly acidic sample media presents several hydronium ions that may compete with cadmium ions for adsorptive sites on the sorbent material. The surface chemistry of the sorbent material is also maximized for adsorption through different mechanisms (physical and chemical) at the optimum pH value. Therefore, the pH of the buffer solution was selected as 6.0 for the adsorptive removal process due to its highest average removal efficiency compared to the other pH values. The volume of pH 6.0 buffer solution was also evaluated by testing 0.50, 1.0, 2.0, 3.0, and 4.0 mL volumes, and the optimum buffer solution volume was selected as 1.0 mL. This observation can be supported by the principle of dilution, where the buffer volumes higher than 1.0 mL ended up diluting the analyte in solution with corresponding high initial volumes. The interaction of the same sorbent amount with analytes in higher volumes becomes limited and this causes the decline in removal efficiency. For the 0.50 mL volume, it can be inferred that its buffer capacity was relatively lower than the optimum 1.0 mL volume.

3.2.2 Effect of Nanoflower Amount

This optimization step was performed to determine the optimum amount of the adsorbent that would yield maximum interaction with the analyte in solution. For this purpose, eight different amounts (10, 20, 30, 40, 50, 60, 75, and 100 mg) of ZT-NFs were tested for 35 mL of sample solutions. The significant increase in the %REs from 10 to 60 mg amounts can be clearly seen in Fig. 5, indicating that the higher amounts offered large surface areas, facilitating the removal of cadmium from the aqueous sample solution compared to the lower amounts. On the other hand, no significant differences in %REs were observed from 60 to 100 mg. Consequently, the optimum nanoflower amount was selected as 75 mg, considering its low standard deviation (SD) value of 6.4 and relatively higher efficiency based on mean values.

3.2.3 Effect of Agitation Type and Period

In order to achieve a homogeneous dispersion of nanoparticles within an aqueous solution, it is essential to employ sample agitation. This process facilitates the uniform distribution of nanoparticles throughout the solution, thereby enhancing their interaction with the analyte and leading to efficient adsorption. The optimizations of pH/volume of buffer solution and nanoflower amount were performed with 2.0 mg/L cadmium solutions. For the optimization of sample agitation type and period, the concentration of cadmium was increased to 4.0 mg/L to determine the impact of these optimization parameters more significantly due to the increasing removal efficiencies. Three agitation procedures including vortexing, ultrasonication, and mechanical mixing were employed to optimize the dispersion of the nanoflowers within the solution and improve the adsorption efficiency. The agitation procedures for all samples were conducted for a period of 3 min. The mechanical mixing technique yielded the highest removal efficiencies, indicating that the technique facilitated enhanced interaction between cadmium and the ZT-NFs. Different periods (1.0, 2.0, 5.0, 10, 20, 30, 40, and 50 min) of mechanical mixing were therefore tested to determine their impact on the removal efficiency for cadmium. There was a significant increase in the %REs from 1.0 to 30 min, followed by no significant differences from 30 to 50 min. Therefore, 30 min of mechanical mixing was selected as the optimum agitation type and period.

The optimized experimental parameters/values determined via the univariate optimization experiments for the adsorptive removal of cadmium by ZT-NFs are detailed in Table 1.

3.3 Equilibrium Modelling in the Batch Adsorption Process

Ultrapure water was used for all the optimization experiments that were performed to determine the optimum parameters/values. Adsorption equilibrium experiments were performed with synthetic wastewater, to mimic a real sample matrix. The raw synthetic wastewater was analyzed under optimized conditions, but no analytical signals were recorded for cadmium. Afterwards, a calibration plot of the absorbance values plotted against their corresponding concentrations in the range of 0.25 to 8.0 mg/L (in synthetic wastewater) was used to determine the equilibrium/residual concentrations (Ci, mg/L) of cadmium in the effluent samples. The calibration plot of cadmium developed for the spiked synthetic wastewater is given in Fig. 6.

After developing the calibration plot, cadmium was spiked in the 4-times diluted synthetic wastewater samples in the range of 1.0 – 40 mg/L. The cadmium concentrations of the effluent samples treated with the ZT-NFs-based adsorptive removal process was calculated via the calibration plot in synthetic wastewater and the calculated average %REs with their SDs for triplicate analyses are given in Table 2.

3.3.1 Langmuir Isotherm Model

The Langmuir equation, which has its basis in the theory of a finite number of uniformly distributed binding sites on the surface of an adsorbent, is widely recognized as the isotherm model that is most commonly employed for modelling adsorption data (Langmuir, 1918; Onkal Engin et al., 2012). This isotherm model has the mathematical equation (non-linear) given in Eq. 2:

In this non-linear equation, the denotations of Ce, KL, qe, and qm represent residual/equilibrium adsorbate concentration (mg/L), Langmuir constant (L/mg), equilibrium adsorption capacity (mg/g), and maximum adsorption capacity (mg/g). The equilibrium adsorption capacity (qe) can be easily calculated via Eq. 3:

where: m is the amount of adsorbent and V is the volume of sample solution (L). After calculating the Ce values from the developed calibration plot and the qe values from Eq. 3, the regression constants qm and KL can be calculated from the linearization of the non-linear Langmuir equation. The linearization of this model utilized in this study is given in Table 3 (Sadeghi et al., 2023).

In the Langmuir model, there is a constant separation factor (RL), which is dimensionless, indicating the isotherm type as: RL = 1 (linear), RL = 0 (irreversible), RL > 1 (undesirable), and 0 < RL < 1 (favorable). The mathematical equation for RL is given in Eq. 4.

In this ZT-NFs-based adsorptive removal study, the data was modelled according to the Langmuir isotherm model. The equilibrium isotherm plot (1/qe against 1/Ce) obtained from the linearization of the Langmuir isotherm equation is given in Fig. 7.

The R2 (coefficient of determination) value of 0.9942 indicated a good fit of this isotherm model (Table 4). The qe and RL values with their corresponding initial concentrations are also given in Table 5. All the RL values represented favorable adsorptive removal of cadmium for the working concentration range (1.0 – 40 mg/L).

4 Conclusion

The development of wastewater treatment processes that serve as feasible alternatives or complements to conventional wastewater treatment plants help to effectively mitigate the release of heavy metals into water bodies. In the scope of this study, ZT-NFs were synthesized via a microwave-assisted hydrothermal technique and used as nanoadsorbents for the adsorptive removal of cadmium from synthetic wastewater. The structure and morphology of the nanoflowers were confirmed by SEM analysis. The dominant parameters of the adsorptive removal process (pH/volume of buffer solution, nanoflower amount, and agitation type/period) were optimized univariately to enhance the overall efficiency of the process. The optimization experiments were carried out in ultrapure deionized water, while the equilibrium adsorption experiments were performed in synthetic wastewater. Cadmium was determined in the influent/effluent samples by a robust analytical instrument, FAAS, which is known to be affordable and compatible with different sample preparation methods. Moreover, the residual cadmium concentrations in the synthetic wastewater were calculated via the calibration plot developed in the sample matrix to improve the quantification accuracy of the method. Percent removal efficiencies of cadmium from synthetic wastewater up to 80% were achieved in the working concentration range. The equilibrium data of the adsorption process was modelled according to the Langmuir isotherm model and the results confirmed that this isotherm model fitted well with the data in the initial concentrations between 1.0 and 40 mg/L. Consequently, favorable adsorption of cadmium onto ZT-NFs was successfully achieved in synthetic wastewater at low concentrations, as confirmed by the Langmuir adsorption isotherm. A sound assumption can be made that the proposed removal method can be extended to other metal ions to achieve similar or better removal efficiencies.

Data Availability

Data will be available upon reasonable request.

References

Abbas, A., Hussain, M. A., Amin, M., et al. (2015). Succinate-bonded pullulan: An efficient and reusable super-sorbent for cadmium-uptake from spiked high-hardness groundwater. Journal of Environmental Sciences, 37, 51–58. https://doi.org/10.1016/j.jes.2015.04.013

Abbas, A., Hussain, M. A., Sher, M., et al. (2017). Design, characterization and evaluation of hydroxyethylcellulose based novel regenerable supersorbent for heavy metal ions uptake and competitive adsorption. International Journal of Biological Macromolecules, 102, 170–180. https://doi.org/10.1016/j.ijbiomac.2017.04.024

Akkaya, E., Chormey, D. S., & Bakırdere, S. (2017). Sensitive determination of cadmium using solidified floating organic drop microextraction-slotted quartz tube-flame atomic absorption spectroscopy. Environmental Monitoring and Assessment, 189, 513.

Ali, H., Khan, E., & Ilahi, I. (2019). Environmental Chemistry and Ecotoxicology of Hazardous Heavy Metals: Environmental Persistence, Toxicity, and Bioaccumulation. Journal of Chemistry, 2019, 6730305. https://doi.org/10.1155/2019/6730305

Alraddadi, S. (2022). Utilization of nano volcanic ash as a natural economical adsorbent for removing cadmium from wastewater. Heliyon, 8, e12460. https://doi.org/10.1016/j.heliyon.2022.e12460

Baskaran, P., & Abraham, M. (2022). Adsorption of cadmium (Cd) and lead (Pb) using powdered activated carbon derived from Cocos Nucifera waste: A kinetics and equilibrium study for long-term sustainability. Sustain Energy Technol Assessments, 53, 102709. https://doi.org/10.1016/j.seta.2022.102709

Cai, X., Li, J., Zhang, Z., et al. (2014). Novel Pb2+ Ion Imprinted Polymers Based on Ionic Interaction via Synergy of Dual Functional Monomers for Selective Solid-Phase Extraction of Pb2+ in Water Samples. ACS Applied Materials & Interfaces, 6, 305–313. https://doi.org/10.1021/am4042405

Cai, D.-R., Yan, H., Han, J., et al. (2023). Efficient and selective removal of ReO4− from highly acid solutions by SnS nanoflowers: Implications for TcO4− sequestration. Environmental Science. Nano, 10, 1494–1503. https://doi.org/10.1039/D3EN00126A

Dias, F. D. S., Guarino, M. E. P., Pereira, A. L. C., et al. (2019). Optimization of magnetic solid phase microextraction with CoFe2O4 nanoparticles unmodified for preconcentration of cadmium in environmental samples by flame atomic absorption spectrometry. Microchemical Journal, 146, 1095–1101. https://doi.org/10.1016/j.microc.2019.02.005

de Guedes, L. F. M., Braz, B. F., Freire, A. S., & Santelli, R. E. (2020). Assessing the harmfulness of high-salinity oilfield-produced water related to trace metals using vortex-assisted dispersive liquid-liquid microextraction combined with inductively coupled plasma optical emission spectrometry. Microchemical Journal, 155, 104714. https://doi.org/10.1016/j.microc.2020.104714

Dou, D., Wei, D., Guan, X., et al. (2022). Adsorption of copper (II) and cadmium (II) ions by in situ doped nano-calcium carbonate high-intensity chitin hydrogels. Journal of Hazardous Materials, 423, 127137. https://doi.org/10.1016/j.jhazmat.2021.127137

Ehrampoush, M. H., Miria, M., Salmani, M. H., & Mahvi, A. H. (2015). Cadmium removal from aqueous solution by green synthesis iron oxide nanoparticles with tangerine peel extract. Journal of Environmental Health Science and Engineering, 13, 84. https://doi.org/10.1186/s40201-015-0237-4

Ersahin, M. E., Ozgun, H., Tao, Y., & van Lier, J. B. (2014). Applicability of dynamic membrane technology in anaerobic membrane bioreactors. Water Research, 48, 420–429. https://doi.org/10.1016/j.watres.2013.09.054

Fontes, A. S., Romero, J. C., Guimarães, L. B., et al. (2020). Development of Method Based on Dispersive Liquid-Liquid Microextraction Air-Assisted for Multi-Element Determination of Cadmium and Manganese in Sugarcane Spirit (Brazilian cachaça) by FAAS. Food Analytical Methods, 13, 222–229. https://doi.org/10.1007/s12161-019-01600-w

Foroutan, R., Mohammadi, R., Peighambardoust, S. J., et al. (2020). Application of nano-silica particles generated from offshore white sandstone for cadmium ions elimination from aqueous media. Environmental Technology & Innovation, 19, 101031. https://doi.org/10.1016/j.eti.2020.101031

Harja, M., Buema, G., Lupu, N., et al. (2021). Fly ash coated with magnetic materials with improved adsorption capacities. Materials (Basel), 14, 63.

Homaeigohar, S. (2020). The nanosized dye adsorbents for water treatment. Nanomaterials, 10, 295.

Jaculine, M. M., Raj, C. J., Kim, H.-J., et al. (2014). Zinc stannate nanoflower (Zn2SnO4) photoanodes for efficient dye sensitized solar cells. Materials Science in Semiconductor Processing, 25, 52–58. https://doi.org/10.1016/j.mssp.2013.11.003

Kasa, N. A., Zaman, B. T., & Bakirdere, S. (2020). Ultra-trace cadmium determination in eucalyptus and rosemary tea samples using a novel method: Deep eutectic solvent based magnetic nanofluid liquid phase microextraction-slotted quartz tube-flame atomic absorption spectrometry. Journal of Analytical Atomic Spectrometry, 35, 2565–2572. https://doi.org/10.1039/d0ja00276c

Kavisri, M., Abraham, M., Namasivayam, S. K. R., et al. (2023). Adsorption isotherm, kinetics and response surface methodology optimization of cadmium (Cd) removal from aqueous solution by chitosan biopolymers from cephalopod waste. Journal of Environmental Management, 335, 117484. https://doi.org/10.1016/j.jenvman.2023.117484

Koju, N. K., Song, X., Wang, Q., et al. (2018). Cadmium removal from simulated groundwater using alumina nanoparticles: behaviors and mechanisms. Environmental Pollution, 240, 255–266. https://doi.org/10.1016/j.envpol.2018.04.107

Langmuir, I. (1918). The adsorption of gases on plane surfaces of glass, mica and platinum. Journal of the American Chemical Society, 40, 1361–1403.

Lei, Z., Chen, L., Hu, K., et al. (2018). Non-aqueous phase cold vapor generation and determination of trace cadmium by atomic fluorescence spectrometry. Spectrochimica Acta Part A: Molecular and Biomolecular Spectroscopy, 203(522), 527. https://doi.org/10.1016/j.saa.2018.06.020

Lin, X., Gan, L., Owens, G., & Chen, Z. (2023). Removal of cadmium from wastewater using biofunctional reduced graphene oxide synthesized by Lysinibacillus sphaericus. Journal of Cleaner Production, 383, 135369. https://doi.org/10.1016/j.jclepro.2022.135369

Lodhi, B. A., Abbas, A., Hussain, M. A., et al. (2019). Design, characterization and appraisal of chemically modified polysaccharide based mucilage from Ocimum basilicum (basil) seeds for the removal of Cd(II) from spiked high-hardness ground water. Journal of Molecular Liquids, 274, 15–24. https://doi.org/10.1016/j.molliq.2018.10.056

Masood, N., Irshad, M. A., Nawaz, R., et al. (2023). Green synthesis, characterization and adsorption of chromium and cadmium from wastewater using cerium oxide nanoparticles; reaction kinetics study. Journal of Molecular Structure, 1294, 136563. https://doi.org/10.1016/j.molstruc.2023.136563

Meira, L. A., & de Souza, Dias F. (2017). Application of constrained mixture design and Doehlert matrix in the optimization of dispersive liquid-liquid microextraction assisted by ultrasound for preconcentration and determination of cadmium in sediment and water samples by FAAS. Microchemical Journal, 130, 56–63. https://doi.org/10.1016/j.microc.2016.07.013

Mohamed, F., Guillaume, D., Abdulwali, N., et al. (2020). ICP-OES assisted determination of the metal content of some fruit juices from Yemen’s market. Heliyon, 6, e04908. https://doi.org/10.1016/j.heliyon.2020.e04908

Moinfar, S., & Khayatian, G. (2017). Continuous sample drop flow-based microextraction combined with graphite furnace atomic absorption spectrometry for determination of cadmium. Microchemical Journal, 132, 293–298. https://doi.org/10.1016/j.microc.2017.01.031

Onkal Engin, G., Muftuoglu, B., & Senturk, E. (2012). Dynamic biosorption characteristics and mechanisms of dried activated sludge and Spirulina platensis for the removal of Cu2+ ions from aqueous solutions. Desalination and Water Treatment, 47, 310–321.

Prasad, K., Gopikrishna, P., Kala, R., et al. (2006). Solid phase extraction vis-à-vis coprecipitation preconcentration of cadmium and lead from soils onto 5,7-dibromoquinoline-8-ol embedded benzophenone and determination by FAAS. Talanta, 69, 938–945. https://doi.org/10.1016/j.talanta.2005.11.040

Punia, P., Aggarwal, R. K., Kumar, R., et al. (2022). Adsorption of Cd and Cr ions from industrial wastewater using Ca doped Ni–Zn nanoferrites: Synthesis, characterization and isotherm analysis. Ceramics International, 48, 18048–18056. https://doi.org/10.1016/j.ceramint.2022.02.234

Rodríguez Giraldo, Y., Rodriguez Sánchez, E., Torres, L. G., Montenegro, A. C., & Pichimata, M. A. (2022). Development of validation methods to determine cadmium in cocoa almond from the beans by ICP-MS and ICP-OES. Talanta Open, 5, 100078. https://doi.org/10.1016/j.talo.2021.100078

Sadeghi, M., Moradian, M., Tayebi, H. A., & Mirabi, A. (2023). Removal of Penicillin G from aqueous medium by PPI@SBA-15/ZIF-8 super adsorbent: Adsorption isotherm, thermodynamic, and kinetic studies. Chemosphere, 311, 136887. https://doi.org/10.1016/j.chemosphere.2022.136887

Sethy, S. K., Kishore, M. V., Bhagat, C., & Kumar, M. (2023). Periodic monitoring of nano clay as the potential adsorbent to remove metal and dyes from wastewater: A review. Total Environment Research Themes, 7, 100067. https://doi.org/10.1016/j.totert.2023.100067

Shao, Z., Xue, M., Liu, Q., et al. (2020). Determination of cadmium in rice bran oils by ICP-MS with rapid ultrasound-assisted acid leaching extraction. Journal of Consumer Protection and Food Safety, 15, 193–198.

Sixto, A., Mollo, A., & Knochen, M. (2019). Fast and simple method using DLLME and FAAS for the determination of trace cadmium in honey. Journal of Food Composition and Analysis, 82, 103229. https://doi.org/10.1016/j.jfca.2019.06.001

Valasques, S. G., dos Santos, A. M. P., de Souza, S. V., et al. (2020). Multivariate optimization for the determination of cadmium and lead in crude palm oil by graphite furnace atomic absorption spectrometry after extraction induced by emulsion breaking. Microchemical Journal, 153, 104401. https://doi.org/10.1016/j.microc.2019.104401

Who, W. H. O. (2011). Cadmium in drinking-water: Background document for development of WHO guidelines for drinking-water quality. World Health Organization.

Yadav, V. K., Ali, D., Khan, S. H., et al. (2020). Synthesis and characterization of amorphous iron oxide nanoparticles by the sonochemical method and their application for the remediation of heavy metals from wastewater. Nanomaterials, 10, 1551.

Yang, Y., Ye, X., He, B., & Liu, J. (2016). Cadmium potentiates toxicity of cypermethrin in zebrafish. Environmental Toxicology and Chemistry, 35, 435–445.

Yuan, X., Yang, L., Liu, S., et al. (2018). An effective analytical system based on an ultraviolet atomizer for trace cadmium determination using atomic fluorescence spectrometry. Analytical Methods, 10, 4821–4826.

ZeiniJahromi, E., Bidari, A., Assadi, Y., et al. (2007). Dispersive liquid–liquid microextraction combined with graphite furnace atomic absorption spectrometry: Ultra trace determination of cadmium in water samples. Analytica Chimica Acta, 585, 305–311. https://doi.org/10.1016/j.aca.2007.01.007

Zergui, A., Aledeh, M., & Hamad, S. (2022). Metallic profile of Zamzam water: Determination of minerals, metals and metalloids by ICP-MS. Journal of Trace Elements and Minerals, 2, 100031. https://doi.org/10.1016/j.jtemin.2022.100031

Acknowledgements

The authors dedicated this publication to the 100th anniversary of the Republic of Türkiye. As scientists raised by Türkiye, they are proud to be citizens of this country.

Funding

Open access funding provided by the Scientific and Technological Research Council of Türkiye (TÜBİTAK).

Author information

Authors and Affiliations

Contributions

Münevver Toprak: Data curation, Formal analysis, Methodology, Validation, Visualization, Writing – original draft.

Barış Yıldız: Formal analysis, Validation, Writing – original draft.

Buse Tuğba Zaman: Data curation, Validation, Visualization, Writing – original draft.

Gamze Dalgıç Bozyiğit: Data curation, Validation, Visualization, Writing – original draft.

İlknur Durukan Temuge: Conceptualization, Data curation, Writing – original draft.

Gülten Çetin: Conceptualization, Co-supervision, Validation, Writing– review & editing.

Sezgin Bakırdere: Conceptualization, Investigation, Methodology, Supervision, Validation, Writing– review & editing.

Corresponding author

Ethics declarations

Ethical Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Consent to Participate

Not applicable.

Consent to Publish

Not applicable.

Competing Interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Toprak, M., Yıldız, B., Zaman, B.T. et al. Microwave-Assisted Hydrothermal Synthesis of Zinc-tin Based Nanoflower for the Adsorptive Removal of Cadmium from Synthetic Wastewater. Water Air Soil Pollut 235, 318 (2024). https://doi.org/10.1007/s11270-024-07129-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-024-07129-x