Abstract

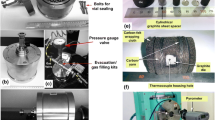

The effect of different regimes of high-energy ball milling (HEBM) on the morphology of reactive Ti–Al powders was studied. It is shown that a “soft” regime of mechanical treatment can be readily used to prepare spheroidal reactive Ti–Al powders with the flow ability suitable for selective laser melting applications. Size distribution of milled powders was found to depend on the diameter of milling balls. Milled powders showed good flow ability of 61.7 and 81.25 s for 2-mm and 6-mm balls, respectively. Combustion reaction in the compacts prepared from milled powders got started at temperatures close to the melting point of Al, and due to the thermal effect of reaction, the temperature jump made a value of about 500°C. The combustion product—Ti–TiAl3 composite—can be recommended for use as a high-temperature structural material.

Similar content being viewed by others

References

X. Ren, H. Shao, T. Lin, and H. Zheng: Mater. Des., 2016, vol.101, pp. 80-87.

A. Levy, A. Miriyev, A. Elliott, S.S. Babu, and N. Frage: Mater. Des., 2017, vol. 118, pp. 198-203.

R. Liu, Z. Wang, T. Sparks, F. Liou, and J. Newkirk: in Laser Additive Manufacturing: Materials, Design, Technologies, and Applications, 2017, pp. 351-71.

S.F.S. Shirazi, S. Gharehkhani, M. Mehrali, H. Yarmand, H.S.C. Metselaar, N. Adib Kadri, and N.A.A. Osman: Sci. Technol. Adv. Mater., 2015, 16 033502.

F. Mangano, M. Bazzoli, L. Tettamanti, D. Farronato, M. Maineri, A. Macchi, and C. Mangano: Lasers Med. Sci., 2013, vol. 28, pp. 1241-47.

P.H. Warnke, H. Seitz, F. Warnke, S.T. Becker, S. Sivananthan, E. Sherry, Q. Liu, J. Wiltfang, and T. Douglas: J. Biomed. Mater. Res. - Part B Appl. Biomater., 2010, vol. 93B, pp. 212-17.

S. Hoeges, A. Zwiren, and C. Schade: Met. Powder Rep., 2017, vol. 72, pp. 11-117.

C.C. Yang, J.L. Hang Chau, C.J. Weng, C.S. Chen, and Y.H. Chou: Mater. Chem. Phys., 2017, vol.202, pp. 151-58.

Y.Y. Kaplanskii, A.A. Zaitsev, Z.A. Sentyurina, E.A. Levashov, Y.S. Pogozhev, P.A. Loginov, and I.A. Logachev: J. Mater. Res. Technol., 2018, vol. 7, pp. 461-68.

G. Chen, S.Y. Zhao, P. Tan, J. Wang, C.S. Xiang, and H.P. Tang: Powder Technol., 2018, vol. 333, pp. 38-46.

V.N. Korzhyk, L.D. Kulak, V.E. Shevchenko, V.V. Kvasnitskiy, N.N. Kuzmenko, X. Liu, Y.X. Cai, L. Wang, H.W. Xie, and L.M. Zou: Mater. Sci. Forum, 2017, vol. 898, pp. 1485-97.

F. Gao and H.M. Wang: Intermetallics, 2008, vol. 16, pp. 202–08.

L.X. Dong and H.M. Wang: J. Alloys Compd., 2008, vol. 465, pp. 83–89.

D. Gu, Y.C. Hagedorn, W. Meiners, K. Wissenbach, and R. Poprawe: Surf. Coatings Technol., 2011, vol. 205, pp. 3285-92.

D. Gu and W. Meiners: Mater. Sci. Eng. A, vol. 527, pp. 7585-92.

Merzhanov A.G., Pis’menskaya E.B., Ponomarev V.I.: Dokl. Phys. Chem., 1998, vol. 363, p. 203-07.

N.F. Shkodich, N.A. Kochetov, A.S. Rogachev, D.Y. Kovalev, and N. V Sachkova: Russ. J. Non-Ferrous Met., 2006, vol. 5, pp. 44–50.

N.F. Shkodich, N.A. Kochetov, A.S. Rogachev, A.E. Grigoryan, M.R. Sharafutdinov, and B.P. Tolochko: Bull. Russ. Acad. Sci. Phys., 2007, vol. 71, pp. 650–52.

Y.S. Itin, V.I. and Naiborodenko: Vysokotemperaturnyi Sintez Intermetallicheskikh Soedinenii (High-Temperature Synthesis of Intermetallic Compounds), Izd. Tomsk. Univ., Tomsk, 1989, p. 214.

N.F. Shkodich, N.A. Kochetov, A.S. Rogachev, A.E. Grigoryan, M.R. Sharafutdinov, and B.P. Tolochko: Bull. Russ. Acad. Sci. Phys., 2007, vol. 71, pp. 650-52.

C. Suryanarayana: Prog. Mater. Sci., 2001, vol. 46, pp. 1-184.

E. Medda, F. Delogu, and G. Cao: Mater. Sci. Eng. A, 2003, vol. 361, pp. 23-28.

A.S. Rogachev, N.F. Shkodich, S.G. Vadchenko, F. Baras, D.Y. Kovalev, S. Rouvimov, A.A. Nepapushev, and A.S. Mukasyan: J. Alloys Compd., 2013, vol. 577, pp. 600–05.

H.C. Yi, A. Petric, and J.J. Moore: J. Mater. Sci., 1992, vol. 27, pp. 6797-6806.

N. Bertolino, M. Monagheddu, A. Tacca, P. Giuliani, C. Zanotti, and U. Anselmi Tamburini: Intermetallics, 2003, vol. 11, pp. 41-49.

Acknowledgments

This work was supported by the Russian Ministry for Science and Higher Education in the framework of the Federal Target Program “Research and Development on Priority Directions of the Scientific and Production Complex of Russia for 2014–2020”, Agreement No. 14.587.21.0051, Project RFMEFI58718X0051.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted 12 April, 2018.

Rights and permissions

About this article

Cite this article

Nepapushev, A.A., Moskovskikh, D.O., Buinevich, V.S. et al. Production of Rounded Reactive Composite Ti/Al Powders for Selective Laser Melting by High-Energy Ball Milling. Metall Mater Trans B 50, 1241–1247 (2019). https://doi.org/10.1007/s11663-019-01553-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-019-01553-9