Abstract

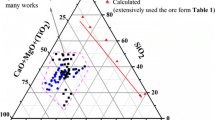

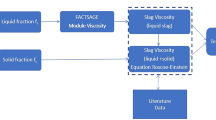

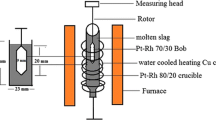

Metallurgical properties of slag are determined to a great extent by its viscosity. High-temperature viscosity measurements are time-consuming and expensive. It is necessary to develop an accurate viscosity model for blast furnace slag in the SiO2-Al2O3-CaO-MgO system using reliable viscosity data. This paper describes a systemic evaluation procedure to determine the viscosity data to be used for model development. 1780 viscosity data from 10 to 65 wt pct SiO2, 3.5 to 40 wt pct Al2O3, 2 to 60 wt pct CaO, and 2 to 38 wt pct MgO in the SiO2-Al2O3-CaO-MgO system have been accepted for model evaluation after critical reviews. The existing 14 viscosity models in SiO2-Al2O3-CaO-MgO system is also reviewed and evaluated. Based on the structure of alumina-silicate slag and evaluated viscosity data, a new viscosity model has been proposed for the system SiO2-Al2O3-CaO-MgO. A new term “probability,” based on the basic oxide and electronegativity, is introduced to calculate the integral activation energy of slag. The model has been evaluated and compared with existing viscosity models in three different composition ranges in SiO2-Al2O3-CaO-MgO system for different applications. The new model reports an outstanding agreement between predictions and experimental data. The industrial implications of the new model have also been discussed in ironmaking and steelmaking processes.

Similar content being viewed by others

References

A.K. Biswas: Principles of Blast Furnace Ironmaking, 2nd ed., Cootha Publication House, Brisbane, Australia, 1981, p. 329.

C. Wu, Y.Q. Sum, D.X. Luo, and Y.X. Lu: Journal of Wuhan University of Science and Technology, 2013, vol.36, pp. 254-57.

J.W. Matousek: The Minerals, Metals & Materials Society, 2015, vol.67, pp. 1216-22.

L. Zhou, X.H. Wang, and J. Wang: J. Iron Steel Res., 2014. vol.21, pp. 70-3.

K.C. Mills and S. Sridhar: Ironmaking Steelmaking, 1999, vol. 26, pp. 262-68.

M. Chen, D. Zhang, M. Kou, and B. Zhao: ISIJ Int., 2014, vol. 54, pp. 2025-30.

L. Forsbacka, L. Holappa, T. Iida, Y. Kita, and Y. Toda: Scand. J. Metall, 2003, vol. 32, pp. 273-80.

Y.M. Gao, S.B. Wang, C. Hong, X.J. Ma, and F. Yang: International Journal of Minerals, Metallurgy, and Materials, 2014, vol. 21, pp. 353-62.

I. Gultyai: Izv. Akad. Nauk SSSR, 1962, vol. 5, pp. 52-65.

V.K. Gupta and V. Seshadri: Trans. Indian Inst. Met., 1973, vol. 26, pp. 55-64.

J.W. Han, E.H. Kwon, S.S. Han, J.H. Chi, B.S. Kim, and J.C. Lee: Mater. Sci. Forum, 2003, vol. 439, pp. 149-55.

E.E. Hofmann: Berg- und hüttenmännische monatshefte, 1959, vol. 106, pp. 397-407.

E.E. Hofmann: Stahl und Eisen, 1959, vol. 79, pp. 846-53.

F. Johannsen and H. Brunion: Zeitschrift fur Erzbergbau und Metallhutten-Wesen, 1959, vol. 12, pp. 272-79.

Y. Kawai: The science reports of the Research Institutes, Tohoku University, Physics, 1952, vol. A, pp. 615–21.

H. Kim, H. Matsuura, F. Tsukihashi, W. Wang, D.J. Min, and I. Sohn: Metall. Mater. Trans. B, 2012, vol. 44, pp. 5-12.

J.R. Kim, Y.S. Lee, and D.J. Min: ISSTech. Conference, 2003, Indianapolis, USA, p. 515.

S.H. Kim and J.D. Seo: Iron & Steelmaker, 1999, vol. 26, pp. 51-7.

T. Koshida, T. Ogasawara, and H. Kishidaka: Tetsu to Hagane, 1981, vol. 67, pp. 1491-97.

P.C.Li and X.J. Ning: Metall. Mater. Trans. B., 2016, vol. 47, pp. 446-57

Y.S. Lee, J.H. Park, D.J. Min, S.H. Yi, and W.W. Huh: Ironmaking Conf. Proc., 2002, vol. 61, pp. 155-65.

Y.S. Lee, D.J. Min, S.M. Jung, and S.H. Yi: ISIJ Int., 2004, vol. 44, 1283-89.

U. Mishra, B. Thakur, and M. Thakur: SEAISI Quarterly, 1994, vol. 23, pp. 72-82.

A.M. Muratov and I.S. Kulikov: Izvestiya Akademii Nauk SSSR. Metally., 1965, vol.1, pp. 57-62.

M. Nakamoto, T. Tanaka, J. Lee, and T. Usui: ISIJ Int., 2004, vol. 44, pp. 2115-19.

H. Park, J.Y. Park, G.H. Kim, and I. Sohn: Steel Res. Int., 2012, vol. 83, pp. 150-56.

N. Saito, N. Hori, K. Nakashima, and K. Mori: Metall. Mater. Trans. B, 2003, vol. 34, pp. 509-11.

C. Scarfe, D. Cronin, J. Wenzel, and D. Kauffman: Am. Mineral., 1983, vol. 68, pp. 1083-88.

A. Shankar, M. Görnerup, A.K. Lahiri, and S. Seetharaman: Metall. Mater. Trans. B, 2007, vol. 38, pp. 911-15.

M. Song, Q. Shu, and D. Sichen: Steel Res. Int., 2011, vol. 82, pp. 260-68.

X.L. Tang, Z.T. Zhang, M. Guo, M. Zhang, and X.D. Wang: J. Iron Steel Res. Int., 2011, vol. 18, pp. 1-17.

G.P. Vyatkin, N.L. Zhilo, and M.Y. Ostroukhov: Izvestiya Vysshikh Uchebnykh Zavedenii. Chernaya Metallurgia., 1962, vol. 5, pp. 25-9.

L.Yao, S.Ren, X.Q.Wang, Q.C.Liu, L.Y.Dong, J.F.Yang, and J.B.Liu: Steel Res.Int., 2016. Vol. 87, pp. 241-49.

Y. Kita, A. Handa, and T. Iida: Journal of High Temperature Society of Japan, 2001, vol. 27, pp. 144-50.

J.S. Machin and D.L. Hanna: J. Am. Ceram. Soc., 1945, vol. 28, pp. 310-16.

J.S. Machin and T.B. Yee: J. Am. Ceram. Soc., 1954, vol. 37, pp. 177-86.

J.S. Machin, T.B. Yee, and D.L. Hanna: J. Am. Ceram. Soc., 1952, vol. 35, pp. 322-25.

L.N. Sheludyakov, E.T. Sarancha, and A.A. Vakhitov: Trans. Inst. Khim. Nauk, Akad. Nauk Kaz. SSR, 1967, vol. 15, pp. 158–63.

A.I. Tsybulnikov, G.A. Toporishchev, G.A. Vachugov, E.D. Mokhir, and V.V. Vetysheva: Izvestiya Vysshikh Uchebnykh Zavedenii. Chernaya Metallurgia, 1973, vol. 2, pp. 5–9.

A.M. Yakushev, V.M. Romashin, and V.A Amfiteatrov: Izvestiya Vysshikh Uchebnykh Zavedenii. Chernaya Metallurgia, 1977, vol. 55–58.

M. Kato and S. Minowa: Trans. Iron Steel Inst. Jpn., 1969, vol. 9, pp. 31-38.

H. Taniguchi: Contrib. Mineral. Petrol., 1992, vol. 109, pp. 295-303.

VDEh: Slag Atlas, 2nd edn, Verlag Stahleisen, Dusseldorf, 1995, p. 351.

G. Leblanc, R. Secco, and M. Kostic: The Measurement, Instrumentation and Sensors Handbook, 1999, Springer, Berlin

E.F. Riebling: Rev. Sci. Instrum., 1963, vol. 34, pp. 568-72.

J.O.M. Bockris, J.D. Mackenzie, and J.A. Kitchener: Trans. Faraday Soc., 1955, vol. 51, pp. 1734-48.

C. Bale, P. Chartrand, S. Degterov, G. Eriksson, K. Hack, R. Ben Mahfoud, J. Melançon, A. Pelton, and S. Petersen: Calphad, 2002, vol. 26, pp. 189-228.

M.Chen, D.W. Zhang, and B. Zhao: Proceeding of 4th Australia-China-Japan Joint Symposium on Iron and Steel-making, 2012, Shenyang, China. pp. 115–27.

S. Sathivel, J. Huang, and W. Prinyawiwatkul: J. Food Eng., 2008, vol. 84, pp. 187-93.

I. Sohn and D.J. Min: Steel Res.Int., 2012, vol. 83, pp. 611-30.

G. Urbain: Steel Res.Int., 1987, vol. 58, pp. 111-6.

P. Riboud, Y. Roux, L. Lucas, and H. Gaye: Fachberichte Huttenpraxis Metallweiterverarbeitung, 1981, vol. 19, pp. 859-69.

T. Iida, H. Sakai, Y. Kita, and K. Shigeno: ISIJ Int., 2000, vol. 40, pp. S110-14.

K.C. Mills and S. Sridhar: National Physical Lab, 1992.

A. Shankar: Ph.D. Thesis, Royal Institute of Technology, Stockholm, 2007.

H.S. Ray and S. Pal: Ironmaking Steelmaking., 2004, vol. 31, pp. 125-30.

X.J. Hu, Z.S. Ren, G.H. Zhang, L.J. Wang, and K.C. Chou: International Journal of Minerals, Metallurgy, and Materials, 2012, vol. 19, pp. 1088-92.

L. Gan and C. Lai: Metall. Mater. Trans. B, 2013, vol. 45, pp. 875-88.

X.L. Tang, M. Guo, X.D. Wang, Z.T. Zhang, and M. Zhang: Beijing Keji Daxue Xuebao, 2010, vol. 32, pp. 1542-46.

M. Suzuki and E. Jak: Metall. Meter. Trans. B, 2013, vol. 44, pp. 1451-65.

A.N. Grundy, H. Liu, I.H. Jung, S.A. Decterov, and A.D. Pelton: Int. J. Mater. Res., 2008, vol. 99, pp. 1185-94.

A.N. Grundy, I.H. Jung, A.D. Pelton, and S.A. Decterov: Int. J. Mater. Res., 2008, vol. 99, pp. 1195-209.

Q. Shu: Ironmaking and Steelmaking., 2015, vol. 42, pp. 641-47.

G.H. Zhang, K.Mills and C. Chou: Steel Res.Int., 2013, vol. 84, pp. 631-7.

J.Frenkel: Acta phys.-chim. URSS., 1935, vol. 3, pp.913-38.

J.A.Duffy and M.D.Ingram: J.Inorg.Nucl.Chem., 1975, vol. 37, pp. 1203-6.

H. Vogel: Phys. Z., 1921, vol. 22, pp. 645-46.

G.S.Fucher: J.Am.Ceram.Soc., 1925, vol. 8, pp. 339-55.

G.Tammann and W. Hesse: Z. Anorg. Allg. Chem., 1926, vol. 156, pp. 245-57.

J.N. Tiwary, S. Sarkar, B. Mishra, and U.K. Mohanty: Emerging Mater. Res., 2013, vol. 2, pp. 152-162.

H. Ramberg: The Journal of Geology, 1952, vol. 1, pp. 331-55.

T. Licko and V. Danek: Physics and chemistry of glasses, 1986, vol. 27, pp. 22-26.

S.G.Bratsch: J.Chem.Educ., 1988, vol. 65, pp. 223-35.

P.M.Bills: J.Iron Steel Inst., 1963, vol. 201, pp. 133-40.

G. Urbain, Y. Bottinga, and P. Richet: Geochimica et Cosmochimica Acta., 1982, vol. 46, pp. 1061-72.

R.A. Lyutikov and L.M. Tsylev: Izv. Vkad. Nauk. SSSR Otd. TSch. Nauk. Metall. Gorn. Delo, 1963, vol. 1, p. 41.

T. Yasukouchi, K. Nakashima and K. Mori: Tetsu-to-Hagane, 1999, vol. 85, pp. 571-7.

S. Tunezo and Y. Kawai: The Research Insitute of Mineral Dressing and Metallurgy, 1951, pp. 492–501.

G.H. Zhang and K.C. Chou: ISIJ Int., 2013, vol. 53, pp. 177-80.

M.J.Toplis and D.B.Dingwell: Geochim. Cosmochim. Acta, 2004, vol. 68, pp. 5169-88.

Acknowledgments

The authors would like to acknowledge the financial support from Shougang Group, China and Rio Tinto Iron Ore, Australia.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 12, 2016.

Rights and permissions

About this article

Cite this article

Han, C., Chen, M., Zhang, W. et al. Evaluation of Existing Viscosity Data and Models and Developments of New Viscosity Model for Fully Liquid Slag in the SiO2-Al2O3-CaO-MgO System. Metall Mater Trans B 47, 2861–2874 (2016). https://doi.org/10.1007/s11663-016-0744-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-016-0744-4