Abstract

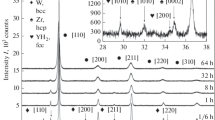

Electron backscatter diffraction (EBSD) has been used to investigate the microstructure and texture-based features of an industrial tertiary oxide scale formed on a micro-alloyed low-carbon steel from a hot strip mill. EBSD-derived maps demonstrate that the oxide scale consists primarily of magnetite (Fe3O4) with a small amount of hematite (α-Fe2O3) which scatters near the surface, at the oxide/steel interface and at the cracking edges. The results extracted from these maps reveal that there is a significant difference between the industrial and the laboratory oxide scales in their grain boundaries, phase boundaries, and texture evolutions. There are high proportions of special coincidence site lattice boundaries Σ3 and Σ13b in the magnetite of the industrial oxide scale, rather than the lower orders of Σ5, Σ7, and Σ17b, which develop in the experimental oxide scale. Within the phase boundaries, the orientation relationships between the magnetite and the hematite correspond to the matching planes and directions {111}Fe3O4||{0001}α-Fe2O3 and {110}Fe3O4||{110}α-Fe2O3. Magnetite in both of these oxide scales develops a relatively weak {001} fiber texture component including a strong {001}〈100〉 cube and a slightly strong {100}〈210〉 texture components. Unlike the {001}〈110〉 rotated cube component in the experimental oxide scale, the magnetite in the industrial tertiary oxide scale develops a strong {112}〈110〉 and a relatively strong {113}〈110〉 and {111}〈110〉 texture components. These findings have the potential to provide a convincing step forward for oxidation research.

Similar content being viewed by others

References

T. Brune, D. Senk, R. Walpot, and B. Steenken: Metall. Mater. Trans. B, 2015, vol. 46, pp. 1400–8.

M. Kiviö, L. Holappa, and T. Iung: Metall. Mater. Trans. B, 2010, vol. 41, pp. 1194–204.

F. Ma, G. Wen, P. Tang, G. Xu, F. Mei, and W. Wang: Metall. Mater. Trans. B, 2011, vol. 42, pp. 81–6.

J. Hu, L.X. Du, J.J. Wang, and Q.Y. Sun: Mater. Des. 2014, vol. 53, pp. 332–7.

T. Jia, Z. Liu, H. Hu, and G. Wang: ISIJ Int., 2011, vol. 51, pp. 1468–73.

X. Yu, Z. Jiang, J. Zhao, D. Wei, C. Zhou, and Q. Huang: Corros. Sci., 2014, vol. 85, pp. 115–25.

M. Krzyzanowski, J.H. Beynon, and C.M. Sellars: Metall. Mater. Trans. B, 2000, vol. 31, pp. 1483–90.

Z. Jiang, X. Yu, J. Zhao, C. Zhou, Q. Huang, G. Luo, and K. Linghu: Adv. Mater. Res., 2014, vol. 1017, pp. 435–40.

H.R. Le, and M.P.F. Sutcliffe: Metall. Mater. Trans. B, 2004, vol. 35, pp. 919–28.

X. Yu, Z. Jiang, J. Zhao, D. Wei, J. Zhou, C. Zhou, and Q. Huang: Surf. Coat. Tech., 2015, vol. 272, pp. 39–49.

X. Yu, Z. Jiang, J. Zhao, D. Wei, C. Zhou, and Q. Huang: Wear, 2015, vol. 332–333, pp. 1286–92.

R.Y. Chen and W.Y.D. Yuen: Oxid. Met., 2003, vol. 59, pp. 433–68.

M. Krzyzanowski, J.H. Beynon, and D.C. Farrugia: Oxide Scale Behavior in High Temperature Metal Processing, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim, 2010.

X.L. Yu, Z.Y. Jiang, X.D. Wang, D.B. Wei, and Q. Yang: Adv. Mater. Res., 2012, vol. 415–7, pp. 853–8.

S.S. Mohapatra, J.M. Jha, S.V. Ravikumar, A. Singh, C. Bhatacharya, S.K. Pal, S. Chakraborty: Exp. Heat Transfer, 2015, vol. 28, pp. 156–73.

R.Y. Chen and W.Y.D. Yuen: Oxid. Met., 2001, vol. 56, pp. 89–118.

J. Miao, T.M. Pollock, and J.W. Jones: Acta Mater., 2012, vol. 60, pp. 2840–54.

K.S. Chan: Metall. Mater. Trans. A, 2015, vol. 46, pp. 2491–505.

H. Abuluwefa, R.I.L. Guthrie, J.H. Root, and F. Ajersch: Metall. Mater. Trans. B, 1996, vol. 27, pp. 993–7.

N. Birks, G.H. Meier, and F.S. Pettit: Introduction to the High Temperature Oxidation of Metals, second ed., Cambridge University Press, New York, 2006, pp. 83–86.

D.J. Young: High Temperature Oxidation and Corrosion of Metals, Elsevier, New York, 2008, pp. 37–42.

S. Hayashi, K. Mizumoto, S. Yoneda, Y. Kondo, H. Tanei, and S. Ukai: Oxid. Met., 2014, vol. 81, pp. 357–71.

B. Gleeson, S.M.M. Hadavi, and D.J. Young: Mater. High. Temp., 2000, vol. 17, pp. 311–9.

S.I. Wright, M.M. Nowell, R. de Kloe, P. Camus, and T. Rampton: Ultramicroscopy, 2015, vol. 148, pp. 132–45.

A.A. Gazder, A.A. Saleh, M.J. Nancarrow, D.R. Mitchell, and E.V. Pereloma: Steel Res. Int., 2015, vol. 86, No. 9999, pp. 1–11.

O. Engler and V. Randle: Introduction to Texture Analysis: Macrotexture, Microtexture, and Orientation Mapping, CRC press, Boca Raton, 2010, pp. 147–69.

Y. Tomota, S. Daikuhara, S. Nagayama, M. Sugawara, N. Ozawa, Y. Adachi, S. Harjo, and S. Hattori: Metall. Mater. Trans. A, 2014, vol. 45, pp. 6103–17.

C. Juricic, H. Pinto, D. Cardinali, M. Klaus, C. Genzel, and A.R. Pyzalla: Oxid. Met., 2010, vol. 73, pp. 15–41.

S. Liu, H. Wu, X. Li, H. Jiang, and D. Tang: J. Iron Steel Res. Int., 2014, vol. 21, pp. 215–21.

S. Birosca, D. Dingley, and R.L. Higginson: J. Microsc., 2004, vol. 213, pp. 235–40.

R.L. Higginson, B. Roebuck, and E.J. Palmiere: Scripta Mater., 2002, vol. 47, pp. 337–42.

B.K. Kim and J.A. Szpunar: Orientation imaging microscopy in research on high temperature oxidation, In: Schwartz, A.J. (Ed.), Electron Backscatter Diffraction in Materials Science, Springer, New York, 2009, pp. 361–393.

L. Suárez, P. Rodríguez-Calvillo, Y. Houbaert, N.F. Garza-Montes-de-Oca, and R. Colás: Oxid. Met., 2011, vol. 75, pp. 281–95.

M. Zhang and G. Shao: Mater. Sci. Eng. A, 2007, vol. 452–3, pp. 189–93.

X. Yu, Z. Jiang, Q. Yang: Adv. Mater. Res., 2011, vol. 145, pp. 111–6.

X. Yu, Z. Jiang, J. Zhao, D. Wei, C. Zhou, and Q. Huang: Corros. Sci., 2015, vol. 90, pp. 140–52.

J.J.L. Mulders, R.T.J.P. Geurts, P.H.F. Trompenaars, and E.G.T. Bosch: Low energy ion milling or deposition, 2014, U.S. Patent Application 14/243,583.

M. Afshar, and S. Zaefferer: Mater. Charact., 2015, vol. 101, pp. 130–5.

H.-J. Bunge: Texture Analysis in Materials Science: Mathematical Methods, Butterworth & Co., Berlin, 1982, pp. 3–41.

H. Okada, T. Fukagawa, H. Ishihara, A. Okamoto, M. Azuma, and Y. Matsuda: ISIJ Int., 1995, vol. 35, pp. 886–91.

M. Graf, and R. Kawalla: Metall. Ital., 2014, vol. 2, pp. 43–49.

A.A. Gazder, V.Q. Vu, A.A. Saleh, P.E. Markovsky, O.M. Ivasishin, C.H. Davies, and E.V. Pereloma: J. Alloys Compound., 2014, vol. 585, pp. 245–59.

X. Zhang, K. Matsuura, and M. Ohno: Micron, 2014, vol. 59, pp. 28–32.

H.E. Evans, H.Y. Li, and P. Bowen: Scripta Mater., 2013, vol. 69, pp. 179–82.

J.A. Nychka, C. Pullen, M.Y. He, and D.R. Clarke: Acta Mater., 2004, vol. 52, pp. 1097–105.

H.E. Evans: Int. Mater. Rev., 1995, vol. 40, pp. 1–40.

G.C. Wood, and J. Stringer: J. Phys. IV, 1993, vol. 3, pp. 65–74.

M. Schütze: Protective Oxide Scales and their Breakdown, Institute of Corrosion and Wiley, Chichester, 1997.

B.M. Morrow, R.J. McCabe, E.K. Cerreta, and C.N. Tomé: Metall. Mater. Trans. A, 2014, vol. 45, pp. 36–40.

J.O. Liu, S. Somnath, and W.P. King: Sensor. Actuat. A-Phys., 2013, vol. 201, pp. 141–7.

F. Yang, X. Zhao, and P. Xiao: Oxid. Met., 2014, vol. 81, pp. 331–43.

J. Robertson, and M.I. Manning: Mater. Sci. Tech., 1990, vol. 6, pp. 81–92.

V. Randle: The Measurement of Grain Boundary Geometry, IOP Publishing, Bristol and Philadelphia, 1993, pp. 33–56.

S. Kobayashi, A. Kamata, and T. Watanabe: Acta Mater., 2015, vol. 91, pp. 70–82.

E.M. Lehockey, A.M. Brennenstuhl, and I. Thompson: Corros. Sci., 2004, vol. 46, pp. 2383–404.

J.H. Kim, B.K. Kim, D.I. Kim, P.P. Choi, D. Raabe, and K.W. Yi: Corros. Sci., 2015, vol. 96, pp. 52–66.

J.Y. Kang, B. Bacroix, H. Réglé, K.H. Oh, and H.C. Lee: Acta Mater., 2007, vol. 55, pp. 4935–46.

A.S. Azar, L.E. Svensson, and B. Nyhus, Int. J. Fatigue, 2015, vol. 77, pp. 95–104.

M. Shimada, H. Kokawa, Z.J. Wang, Y.S. Sato, and I. Karibe: Acta Mater., 2002, vol. 50, pp. 2331–41.

S. Tsurekawa, S. Nakamichi, and T. Watanabe: Acta Mater., 2006, vol. 54, pp. 3617–26.

M.A. Arafin, and J.A. Szpunar: Corros. Sci., 2009, vol. 51, pp. 119–28.

R. Pokharel, J. Lind, A.K. Kanjarla, R.A. Lebensohn, S.F. Li, P. Kenesei, R.M. Suter, and A.D. Rollett: Annu. Rev. Condens. Matter Phys., 2014, vol. 5, 317–46.

Acknowledgments

We are grateful to Dr. Daijun Yang at Shougang Research Institute of Technology, China, for the provision of the steel samples. Special thanks are given to Dr. Azdiar Gazder and Dr. Mitchell Nancarrow for their support and sharing enormous experiences on sample preparation and EBSD. The authors acknowledge the use of facilities within the UOW Electron Microscopy Centre. The authors wish to gratefully acknowledge the help of Dr. Madeleine Strong Cincotta in the final language editing of this paper.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Manuscript submitted March 29, 2015.

Rights and permissions

About this article

Cite this article

Yu, X., Jiang, Z., Zhao, J. et al. A Comparison of Texture Development in an Experimental and Industrial Tertiary Oxide Scale in a Hot Strip Mill. Metall Mater Trans B 46, 2503–2513 (2015). https://doi.org/10.1007/s11663-015-0443-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-015-0443-6