Abstract

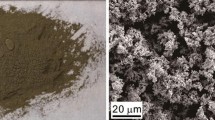

We demonstrate a new continuous smelting process for Ti that combines magnesiothermic reduction of TiCl4 into liquid Bi and refining by vacuum distillation. TiCl4 is reduced by Mg into liquid Bi to form Bi-Ti liquid alloys, and subsequently refined by vacuum distillation. The Bi-Ti liquid alloys can be easily transferred from a reduction vessel to a refining vessel; consequently, the reduction and refining steps can be performed continuously. Bi-Ti alloys with various compositions were confirmed to form, and the compositions were controllable via adjustment of the nominal composition of TiCl4, Mg, and Bi. After reduction, the alloys were efficiently separated from MgCl2 by differences in their densities. In addition, vacuum distillation of the alloys purified Ti to be greater than 99.6 at pct. Moreover, consideration of the heat balance in the reduction step indicated that the proposed process has the potential to unlimitedly improve the feed rate of TiCl4 when the concentration of Ti in the alloy is 6 to 7 at pct.

Similar content being viewed by others

References

Y. Kado, A. Kishimoto, and T. Uda: J. Electrochem. Soc., 2013, vol. 160 (10), pp. E139–42.

W.W. Gleave and J.P. Quin: US Patent, 2757135, 1956.

K. Sato and E. Kimura: Shigen-to-Sozai, 1989, vol. 105, pp. 623–26.

G. P. Vassilev: Z. Metallk., 2004, vol. 95, pp. 813–17.

Scientific Group Thermodata Europe (SGTE): Springer-Verlag, Berlin-Heidelberg, 1999.

S. Maruyama, Y. Kado, and T. Uda: J. Phase Equilib. Diff., 2013, vol. 34(4), pp. 289–96.

J. L. Murray: Phase Diagrams of Binary Titanium Alloys, ASM, Ohio, 1987, p. 282.

T. Tomonari: Chitan kogyo to sono tenbo (Japanese), The Japan Titanium Society, Japan, 2001.

A. Moriya, and A. Kanai: Shigen-to-Sozai, 1993, vol. 109, pp. 1164–69.

M.W. Chase, C.A. Davies, J.R. Downey, D.J. Frurip, R.A. McDonald, and A.N. Syverud: JANAF Thermochemical Tables Third Edition., JPCRD 14, Suppl. 1, 1985, p. 1856.

M. Chase, Jr.: NIST-JANAF, Thermochemical Tables Fourth Edition., Monograph 9 (Part I and Part II), 1998, p. 1963.

Acknowledgments

This study was financially supported by the Advanced Low Carbon Technology Research and Development Program (Japan Science and Technology Agency). The authors would like to acknowledge Kamioka Mining & Smelting Co., Ltd. for supplying the Bi metal used in this study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted April 9, 2014.

Rights and permissions

About this article

Cite this article

Kado, Y., Kishimoto, A. & Uda, T. New Smelting Process for Titanium: Magnesiothermic Reduction of TiCl4 into Liquid Bi and Subsequent Refining by Vacuum Distillation. Metall Mater Trans B 46, 57–61 (2015). https://doi.org/10.1007/s11663-014-0164-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-014-0164-2