Abstract

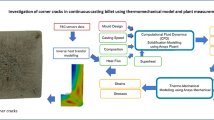

Billets produced by continuous casting sometimes show the presence of subsurface cracks that can compromise the quality of the final product. The presence of these cracks is revealed by Baumann prints of billet cross sections in which the chill zone is visible and the short radial cracks are located only where the chill zone thickness is thinner. This experimental finding induces the hypothesis that cracks are formed as a result of the presence of unevenness in the mold heat extraction around the billet perimeter. Cracks start to open in the dendritic front in regions where the shell growth in the mold is slower. The study presented in this article focused on steels with a sulfur content of about 300 ppm. The Baumann prints taken from billet samples of numerous different heats allowed detecting the presence of subsurface cracks and their location nearby visible chill zone thinning areas. To understand the mechanisms of crack formation and to define the possible corrections, a modeling activity has been carried out using the finite element technique on 148-mm diameter billets continuously cast at TenarisDalmine (Dalmine, Italy). The model performs a two-dimensional thermomechanical analysis of the solidification in the mold and within about 4 cm below the mold exit, along which the shell surface is cooled only by radiation to the environment, before the sprays of the first ring impact on the strand. The model includes the contact of the shell with the mold inner surface, which moves according to taper and distortion (this last part is calculated by means of a separate mold model); the steel creep behavior; the calculation of the heat transfer through the gap depending on the local mutual distance between the two surfaces; the effect of the liquid steel fluid dynamics on the solidification growth as a result of the temperature distribution; and the calculation of a hot tearing indicator represented by the porosity fraction caused by mechanical strains applied at the dendrite roots. From the simulation results, it is concluded that subsurface cracks are generated in the space between the mold exit and the first cooling ring; the involved mechanisms of formation also are withdrawn. Nucleation of MnS precipitates of large dimensions is an additional cause of defectiveness in controlled sulfur steels. As a final conclusion of this work, the most important actions to eliminate subsurface cracks are derived.

Similar content being viewed by others

Abbreviations

- C:

-

carbon content dependent parameter (Pa–n s–m–1)

- d air :

-

M, air gap thickness

- d f :

-

M, flux layer thickness

- k air :

-

air thermal conductivity (W/(mK))

- k f :

-

flux layer lattice thermal conductivity (W/(mK))

- f l :

-

liquid fraction

- f s :

-

solid fraction

- \( f_{\text{p}}^{\text{l}} \) :

-

porosity resulting from shrinkage

- \( f_{\text{p}}^{\text{s}} \) :

-

porosity due to mechanical strains

- g :

-

gravity acceleration (m/s2)

- I :

-

hot cracking/hot tearing index

- m :

-

time exponent in the constitutive equation

- n :

-

equivalent stress exponent

- n Q :

-

z exponent in the heat flux equation

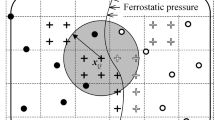

- p :

-

Ferrostatic pressure (Pa)

- Q(z):

-

mold heat flux at a distance z from meniscus (W/m2)

- Q T :

-

activation energy constant (K)

- \( \overline{Q} \) :

-

average mold heat flux (W/m2)

- R cont :

-

contact thermal resistance ((m2K)/W)

- R tot :

-

global thermal resistance ((m2K)/W)

- R irr :

-

radiation thermal resistance ((m2K)/W)

- R f :

-

flux layer thermal resistance ((m2K)/W)

- R air :

-

air gap thermal resistance ((m2K)/W)

- R fmin :

-

flux layer thermal resistance at the meniscus ((m2K)/W)

- t :

-

time (s)

- T :

-

absolute temperature (K)

- Tl, Th:

-

reference temperatures in the steel conductivity curve (K)

- T liq :

-

liquidus temperature (K)

- T m :

-

mold inner surface temperature (K)

- T s :

-

shell surface temperature (K)

- v l :

-

liquid velocity (m/s)

- v p :

-

pore velocity (m/s)

- v s :

-

solid velocity (m/s)

- v c :

-

casting speed (m/s)

- z :

-

distance below meniscus (m)

- z m :

-

mold wetted height (m)

- α(T):

-

instantaneous linear thermal expansion coefficient (1/K)

- ΔT n :

-

bulk heterogeneous nucleation undercooling (K)

- ΔT c :

-

constitutional undercooling (K)

- ε :

-

emissivity through the gap

- ε el :

-

equivalent elastic strain

- ε in :

-

equivalent inelastic strain

- ε th :

-

equivalent thermal strain increment

- \( {\dot\varepsilon}_{in}\) :

-

equivalent inelastic strain rate (1/s)

- \( \dot{\varepsilon }_{xx} \), \( \dot{\varepsilon}_{yy} \), \( \dot{\varepsilon }_{zz} \):

-

main compontents of the mechanical strain rate tensor (s–1)

- ρ :

-

liquid steel density (kg/m3)

- ρ l :

-

liquid density (kg/m3)

- ρ s :

-

solid density (kg/m3)

- σ :

-

Stefan–Boltzmann constant (W/(m2K4))

- σ e :

-

equivalent stress (Pa)

References

J.K. Park, B.G. Thomas, and I.V. Samarasekera: Ironmaking Steelmaking, 2002, vol. 29, no. 5, pp. 359-75.

C. Li and B.G. Thomas: Metall. Mater. Trans. B, vol. 35B, 2004, pp. 1151–72.

M.R. Ridolfi, A. Gotti, J.J. Laraudogoitia, and V. Santisteban: Ironmaking Steelmaking, vol. 31, no. 5, 2004, pp. 371-75.

Y. Hebi, Y. Man, Z. Huiying, and F. Dacheng: ISIJ Int., 2006, vol. 46, no. 4, pp. 546-52.

K. Harste and K. Schwerdtfeger: ISIJ Int., vol. 43, 2003, no. 7, pp. 1011-20.

K. Schwerdtfeger, M. Sato, and K.-H. Tacke: Metall. Mater. Trans. B, 1998, vol. 29B, pp. 1057-68.

B.G. Thomas, W.R. Storkman, and A. Moitra: Proc. of the 6th Int. Iron and Steel Congress, Nagoya, Japan, 1990, pp. 348–54.

P.F. Kozlowski, B.G. Thomas, J.A. Azzi, and H. Wan: Metall. Trans. A, 1992, vol. 23A, pp. 903-18.

D.J. Seol, Y.M. Won, K.H. Oh, Y.C. Shin, and C.H. Yim: ISIJ Int., 2000, vol. 40, no. 4, pp. 356-63.

H.N. Han, Y.G. Lee, K. Kim, K.H. Oh, and D.N. Lee: Mater. Sci. Eng. A, 1996, vol. A206, pp. 81-89.

K.J. Seol, Y.M. Won, T.J. Yeo, K.H. Oh, J.K. Park, and C.H. Yim: ISIJ Int., 1999, vol. 39, pp. 91-98.

A. Yamanaka, K. Nakajima, K, Yasumoto, H. Kawashima, and K. Nakai: Proc. of the 5 th Int. Conf. on Casting, Welding and Advanced Solidification Processes, Warrendale, PA, 1991, pp. 279–84.

Y.M. Won, T.J. Yeo, D.J. Seol, and K.H. Ho: Metall. Mater. Trans. B, 2000, vol. 31B, pp. 779-94.

M. Bellet, O. Cerri, M. Bobadilla, and Y. Chastel: Metall. Mater. Trans. A, 2009, vol. 40A, pp. 2705-17.

M. Rappaz, J.-M. Drezet, and M. Gremaud: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 449-55.

C. A. Monroe and C. Beckermann: Mater. Sci. Eng. A, 2005, vol. 413–414, pp. 30–36.

M. De Santis and A. Ferretti: ISIJ Int., 1996, vol. 36, no. 6, pp. 673-80.

J.H. Weiner and B.A. Boley: J. Mech. Phys. Solids, 1963, vol. 11, pp. 145-54.

J. Miettinen: Metall. Trans. A, 1992, vol. 23A, pp. 1155-70.

J. Miettinen: Metall. Mater. Trans. B, 2000, vol. 31B, pp. 365-79.

M. El-Bealy: Metall. Mater. Trans. B, 2000, vol. 31B, pp. 331-43.

M. El-Bealy: Metall. Mater. Trans. B, 2000, vol. 31B, pp. 345-55.

M.R. Bridge and G.D. Rogers: Metall. Trans. B, 1984, vol. 15B, pp. 581-89.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted February 10, 2010.

Rights and permissions

About this article

Cite this article

Ridolfi, M.R., Fraschetti, S., de Vito, A. et al. Mathematical Modeling of Hot Tearing in the Solidification of Continuously Cast Round Billets. Metall Mater Trans B 41, 1293–1309 (2010). https://doi.org/10.1007/s11663-010-9427-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-010-9427-8