Abstract

Mesoscopic obstacles (e.g., precipitates) serve as an important strengthening and hardening mechanism in metallic alloy systems. Several example material systems include Mg and Al alloys as well as those found in nuclear reactors. Material strength in these systems originates from dislocation–obstacle interactions, in which the obstacles impede the motion of dislocations. The spatial distribution of obstacles in alloy systems is known to be stochastic in nature. Since alloy strengthening scales inversely with obstacle spacing, a spatial distribution of obstacles yields a statistical distribution of strengths. To elucidate relations between planar obstacle density (\(\rho \)), size (D), and the statistical distribution of alloy strength (\(\tau_{crit}\)), we conduct a large number of simulations, yielding statistically representative samples of \(\tau _{crit}\) for randomly generated spatial distributions of obstacles. We interpret the simulation results probabilistically, treating \(\tau _{crit}\) as a random variable with an associated distribution function. To rationalize our results, we develop a weakest link type statistical analysis in which the key quantity is the spatial distribution of link lengths between obstacles. Our analysis yields an expectation and standard deviation of \(\tau _{crit}\) which approximately scale with \(\sim \sqrt{\rho } \ln (D)\). Our analysis corroborates our simulations and unifies similar studies found in the literature.

Similar content being viewed by others

Change history

19 June 2023

A Correction to this paper has been published: https://doi.org/10.1007/s11661-023-07102-z

References

E. Orowan: Z. Angew. Phys., 1934, vol. 89(9), pp. 634–59. https://doi.org/10.1007/BF01341480.

A.J.E. Foreman and M.J. Makin: Philos. Mag., 1966, vol. 14, pp. 911–24.

A.J.E. Foreman and M.J. Makin: Can. J. Phys., 1967, vol. 45, pp. 511–17.

U.F. Kocks: Philos. Mag., 1966, vol. 13, pp. 541–66.

U.F. Kocks: Can. J. Phys., 1967, vol. 45, pp. 737–55.

P.S. Phani, K.E. Johanns, E.P. George, and G.M. Pharr: Acta Mater., 2013, vol. 61, pp. 2489–99.

G. Peterffy, P.D. Ispanovity, M.E. Foster, X. Zhou, and R.B. Sills: Mater. Theory, 2020, vol. 4, p. 66.

Y. Hu and W.A. Curtin: J. Mech. Phys. Solids, 2021, vol. 151, 104378.

L.K. Aagesen, J. Miao, J.E. Allison, S. Aubry, and A. Arsenlis: Metall. Mater. Trans. A, 2018, vol. 49A, pp. 1908–15.

J.F. Nie: Metall. Mater. Trans. A, 2012, vol. 43A, pp. 3891–39.

J.-F. Nie: 20-Physical metallurgy of light alloys, in Physical Metallurgy. D.E. Laughlin and K. Hono, eds., Elsevier, Oxford, 2014, pp. 2009–56.

J. Hernandez-Sandoval, M.H. Abdelaziz, H.W. Doty, and F.H. Samuel: Adv. Mater. Sci. Eng., 2021, vol. 2021, p. 9933168.

C.V. Singh and D.H. Warner: Metall. Mater. Trans. A, 2013, vol. 44A, pp. 2625–44.

G. Esteban-Manzanares, E. Martinez, J. Segurado, L. Capulungo, and J. Llorca: Acta Mater., 2019, vol. 162, pp. 189–201.

J. Hirsch: Mater. Sci. Forum, 1997, vol. 242, pp. 33–50.

J. Miao, M. Li, J. Allison: Proceedings of the 9th international conference on magnesium alloys and their applications: in: 9th International Conference on Magnesium Alloys and Their Applications: July 8–12, 2012, 2012.

S. Queyreau, G. Monnet, and B. Devincre: Acta Mater., 2010, vol. 58, pp. 5586–95.

C. Sobie, N. Bertin, and L. Capulungo: Metall. Mater. Trans. A, 2015, vol. 46, pp. 3761–72.

W. Cui, Y. Cui, and W. Liu: Scripta Mater., 2021, vol. 201, 113959.

A. Lehtinen, L. Laurson, F. Granberg, K. Nordlund, and M.J. Alava: Sci. Rep., 2018, vol. 8, p. 6914.

R. Li, R.C. Picu, and J. Weiss: Phys. Rev. E, 2010, vol. 82, 022107.

R.C. Picu, R. Li, and Z. Xu: Mater. Sci. Eng. A, 2009, vol. 502, pp. 164–71.

M. Hiratani and V.V. Bulatov: Philos. Mag. Lett., 2004, vol. 84, pp. 461–70.

V. Mohles: Philos. Mag. A, 2001, vol. 81, pp. 971–90.

V. Mohles: Mater. Sci. Eng. A, 2001, vol. 319–321, pp. 201–05.

Y. Dong, T. Nogaret, and W.A. Curtin: Metall. Mater. Trans. A, 2010, vol. 41, pp. 1954–60.

B.A. Szajewski, J.C. Crone, and J. Knap: Materialia, 2020, vol. 11, 100671.

J. Friedel: Dislocations: International Series of Monographs on Solid State Physics, Elsevier, Amsterdam, 2013.

R.C. Picu and R. Li: Acta Mater., 2010, vol. 58, pp. 5443–46.

Y. Gu, D.W. Eastman, K.J. Hemker, and J.A. El-Awady: J. Mech. Phys. Solids, 2021, vol. 147, 104245.

A. Arsenlis, W. Cai, M. Tang, M. Rhee, T. Oppelstrup, G. Hommes, T.G. Pierce, and V.V. Bulatov: Modell. Simul. Mater. Sci. Eng., 2007, vol. 15, p. 553.

C.R. Hutchinson, J.F. Nie, and S. Gorsse: Metall. Mater. Trans. A, 2005, vol. 36A, pp. 2093–05.

C.S. Roberts: Magnesium and Its Alloys, Wiley, Hoboken, 1960.

S. Wenner, C.D. Marioara, S.J. Andersen, and R. Holmestad: Int. J. Mater. Res., 2012, vol. 103(8), pp. 948–54. https://doi.org/10.3139/146.110795.

T.A. Parthasarathy, S.I. Rao, D.M. Dimiduk, M.D. Uchic, and D.R. Trinkle: Scripta Mater., 2007, vol. 56, pp. 313–16.

B.A. Szajewski, J.C. Crone, and J. Knap: Philos. Magn. Lett., 2019, vol. 99, pp. 77–86.

D.J. Bacon, U.F. Kocks, and R.O. Scattergood: Philos. Magn., 1973, vol. 28, pp. 1241–63.

J.P. Hirth and J. Lothe: Theory of Dislocations, 2nd ed. Wiley, New York, 1982.

Acknowledgments

BAS, JCC and JK were supported by the CCDC Army Research Laboratory’s Enterprise for Multiscale Research of Materials. Computing support was provided by the DoD Supercomputing Resource Center located at the CCDC Army Research Laboratory.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Review of Dislocation Line Tension

In this section we provide a salient review of the elastic dislocation line tension. More details may be found in References.[27,36,37,38] Consider a dislocation network with line energy W(S), dependent on the configuration of the dislocation line S. For a small change in the configuration of the dislocation (\(\text{d}S\)) there is an associated small change in the energy of the dislocation line, i.e.,

In this expression, \(\Gamma (S) \equiv \partial W(S)/\partial S\) represents the dislocation line tension. It bears emphasis that \(\Gamma (S)\) depends on the configuration of the entire dislocation network; elastic interactions between dislocation segments are nonlocal. Given this fact, unique dislocation configurations yield unique values of \(\Gamma \). One example is the Frank–Read dislocation source, which is comprised an isolated bowing dislocation segment pinned at two points separated by \(L_{crit}\), (cf. Reference 36),

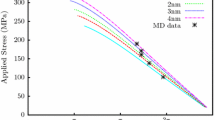

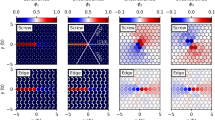

in this expression \(A(\theta ) \equiv (1-\nu \sin ^2(\theta ))/(1-\nu )\) for dislocation character angle \(\theta \) and Poisson’s ratio \(\nu \). A second example is the hexagonal lattice bowout for a dislocation bypassing the lattice depicted in the inset of Figure 1(a),[27]

In deriving \(\Gamma _{FR}\) and \(\Gamma _{hex}\) the notion of dislocation core energy is excluded. As a consequence, both of these expressions include a term \(\mathcal {O}(1)\) which is materials system specific and beyond the scope of the analyses. In surveying the literature, another more well-known example that also describes a dislocation bypassing the hexagonal lattice depicted in the inset of Figure 1(a) is that developed by Bacon et al.[37]:

where \(\bar{D} \equiv DL_{crit}/(D+L_{crit})\). The constant of 0.7 in this expression was best-fit to simulation data. Within the same work Bacon et al.[37] extend \(\Gamma _{BKS, hex}\) to describe bypass through a field of randomly distributed obstacles:

This expression has been employed in several subsequent works to describe bypass through a field of randomly distributed obstacles.[17,18] Each of these expressions (A2) to (A5) relate a surrounding dislocation network to forces on an individual bowing dislocation segment. As such, Eq. [1] yields the critical bypass stress for a bowing dislocation segment of length \(L_{crit}\) embedded in a dislocation network described by any of these expressions for \(\Gamma \).

Standard Error Analysis

From our numerical simulations, we would like to estimate the population distribution of \(\tau _{crit}\) along with the mean, standard deviation and skew; however, due to finite sample sizes, we are limited to computing a sample distribution, sample mean (\(\mathbb {E}[\tau _{crit}]\)), sample standard deviation (\(\mathbb {STD}[\tau _{crit}]\)) and sample skew (\(\mathbb {SKEW}[\tau _{crit}]\)), as tabulated in Table III. Each of these statistics have inherent variability across sets of n samples. Employing the distributions in Figure 3, determined as determined by simulations, we can quantify the uncertainty in our simulated \(\mathbb {E}[\tau _{crit}]\), \(\mathbb {STD}[\tau _{crit}]\) and our maximum likelihood estimate of the line tension, \(\Gamma _{MLE}\), with respect to n.

In the following analysis we focus on the large obstacles high density condition (for which we have 446 samples), but emphasize that similar trends are observed for all (D, \(\rho \)) parameter sets. By assuming our simulation data represents the true population, we draw n samples with replacement of \(\tau _{crit}\) and compute the sample mean, \(\bar{\tau }_{crit}\), the sample standard deviation s, and \(\Gamma _{MLE}\). We repeat this process 100, 000 times for a fixed n for several values of n between \(n=5\) and \(n=1000\). The PDFs for \(\bar{\tau }_{crit}\), normalized \(\Gamma _{MLE}\), and s for \(n=[5,20,446]\) samples are shown in Figures 7(a) to (c), respectively. The PDFs for \(n=5\) and \(n=20\) correspond to sample sizes typically employed in previous studies[8,9,18,19] and \(n=446\) is the sample size used in this work. While the means of these distributions are the same in \(\bar{\tau }_{crit}\) and \(\Gamma _{MLE}\) and similar in s to those in Table III, the PDFs show that these statistics calculated from a single set of 5 or 20 samples may vary from the population values. For \(\bar{\tau }_{crit}\), the variability is relatively small; when \(n=5\), the probability is less than 4 pct that the sample mean is more than 10 pct from the population mean. Therefore, small sample sizes are sufficient when only interested in the mean response. On the other hand, 5 samples can produce a significant spread in the value for s. In Figure 7(c) the population value is assumed to be 4.6, yet 5 samples may produce values ranging from less than 2 to greater than 8.

By increasing n, the sample estimates of \(\bar{\tau }_{crit}\), \(\Gamma _{MLE}\) and s become more precise. This precision is quantitatively measured by the standard error (SE), defined as the standard deviation of the sample statistics. The SE values for \(\bar{\tau }_{crit}\), \(\Gamma _{MLE}\) and s are shown in Figure 5 as a function of n using the large obstacles high density condition simulation data for \(\tau _{crit}\) along with SE for the mean and standard deviation as obtained from a Gaussian distribution with matching first and second statistical moments. The SE decays slowly as \(n^{-1/2}\). The SE of the mean from the simulation data matches identically with the Gaussian distribution. This result is not surprising as it is a direct consequence of the central limit theorem. The SE of the standard deviation does not match the Gaussian. However, the Gaussian provides a tight lower bound. The results in Figures 7 and 5 suggest that the sample sizes employed in this work are able to precisely estimate \(\mathbb {E}[\tau _{crit}]\), \(\Gamma _{MLE}\), and \(\mathbb {STD}[\tau _{crit}]\).

Rights and permissions

About this article

Cite this article

Szajewski, B.A., Crone, J.C. & Knap, J. Statistical Modeling of the Orowan Bypass Mechanism for Randomly Distributed Obstacles. Metall Mater Trans A 54, 2178–2190 (2023). https://doi.org/10.1007/s11661-023-06990-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-023-06990-5