Abstract

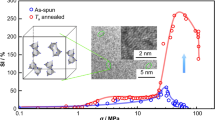

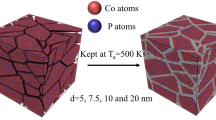

Structural relaxations of grain boundary and glass–glass interfaces (GGIs) play an important role in the mechanical behaviors of polycrystalline metals and metallic nano-glasses (NGs), respectively. Although the former has been well investigated by anelastic or mechanical spectrum measurement, such meaningful technique has not been applied to characterize the structural relaxation of GGIs in NGs as far. In this work, the structural relaxations in Co–Fe–Ni–P NGs with various average sizes (Davg) of glassy grains are investigated by anelastic measurements, which have been synthesized by a pulse electrodeposition method. The results provide direct evidences that a new glass phase could be formed at interfaces in NGs, as characterized by an activation energy (0.91 eV) for glass transition of GGIs much different than that (1.99 eV) in the interiors of glassy grains. From the analyses on dynamical scaling for mechanical losses (Q−1) in the glass and supercooled-liquid (SC-liquid) states, i.e., \({Q}^{-1}\propto ({\omega )}^{-n}\), where \(\omega \) is the angular frequency, it is suggested that the atomic structures at GGIs in NGs with Davg < 150 nm could be dominated by solid-like atomic clusters, whereas those in NGs with Davg > 250 nm might be liquid-like. The size effects on the glass forming ability of NGs are also quantitatively measured by exponents of the dynamical scaling in the SC-liquid state, suggesting that NGs with Davg < 40 nm could be good glass formers. The atomic structures at GGIs revealed in this work could facilitate the development of NGs with desirable mechanical properties through GGI engineering.

Similar content being viewed by others

References

H. Gleiter: Beilstein J. Nanotechnol., 2013, vol. 4, pp. 517–33.

H. Gleiter, T. Schimmel, and H. Hahn: Nano Today, 2014, vol. 9, pp. 17–68.

N. Chen, D.V. Louzguine-Luzgin, and K. Yao: J. Alloys Compd., 2017, vol. 707, pp. 371–78.

T. Feng, H. Hahn, and H. Gleiter: Acta Phys. Sin., 2017, vol. 66, p. 176110.

S.V. Ketov, X. Shi, G. Xie, R. Kumashiro, A.Y. Churyumov, A.I. Bazlov, N. Chen, Y. Ishikawa, N. Asao, H. Wu, and D.V. Louzguine-Luzgin: Sci. Rep., 2015, vol. 5, p. 7799.

K. Wu, F. Chu, Y. Meng, K. Edalati, Q. Gao, W. Li, and H.-J. Lin: J. Mater. Chem. A, 2021, vol. 9, pp. 12152–60.

X. Wang, F. Jiang, H. Hahn, J. Li, H. Gleiter, J. Sun, and J. Fang: Scr. Mater., 2016, vol. 116, pp. 95–99.

Q. Hu, J. Wu, and B. Zhang: Phys. B, 2017, vol. 521, pp. 28–31.

F.C. Li, T.Y. Wang, Q.F. He, B.A. Sun, C.Y. Guo, T. Feng, and Y. Yang: Scr. Mater., 2018, vol. 154, pp. 186–91.

C. Guo, Y. Fang, F. Chen, and T. Feng: Intermetallics, 2019, vol. 110, p. 106480.

C. Pei, R. Zhao, Y. Fang, S. Wu, Z. Cui, B. Sun, S. Lan, P. Luo, W. Wang, and T. Feng: J. Alloys Compd., 2020, vol. 836, p. 155506.

S.P. Singh, M.R. Chellali, L. Velasco, Y. Ivanisenko, E. Boltynjuk, H. Gleiter, and H. Hahn: J. Alloys Compd., 2020, vol. 821, p. 153486.

T. Li and G. Zheng: Metall. Mater. Trans. A, 2021, vol. 52, pp. 1939–46.

Q. Yang, C.-Q. Pei, H.-B. Yu, and T. Feng: Nano Lett., 2021, vol. 21, pp. 6051–56.

S.H. Nandam, R. Schwaiger, A. Kobler, C. Kübel, C. Wang, Y. Ivanisenko, and H. Hahn: J. Mater. Res., 2021, vol. 36, pp. 2903–14.

J.L. Ma, H.Y. Song, M.R. An, W.W. Li, and R.Q. Han: J. Non. Cryst. Solids, 2021, vol. 553, p. 120464.

S. Yuan and P.S. Branicio: Scr. Mater., 2021, vol. 194, p. 113639.

O. Adjaoud and K. Albe: Front. Mater., 2021, vol. 8, p. 664220.

C. Kalcher, O. Adjaoud, and K. Albe: Front. Mater., 2020, vol. 7, p. 223.

S. Yuan and P.S. Branicio: Int. J. Plast., 2020, p. 102845.

S.D. Feng, Y.D. Liu, L.M. Wang, and R.P. Liu: J. Non. Cryst. Solids, 2020, vol. 546, p. 120265.

A. Baksi, S.H. Nandam, D. Wang, R. Kruk, M.R. Chellali, J. Ivanisenko, I. Gallino, H. Hahn, and S. Bag: ACS Appl. Nano Mater., 2020, vol. 3, pp. 7252–59.

M. Ghafari, X. Mu, J. Bednarcik, W.D. Hutchison, H. Gleiter, and S.J. Campbell: J. Magn. Magn. Mater., 2020, vol. 494, p. 165819.

J. Cheng, T. Li, S. Ullah, F. Luo, H. Wang, M. Yan, and G. Zheng: Nanotechnology, 2020, vol. 31, p. 385704.

J.Q. Wang, N. Chen, P. Liu, Z. Wang, D.V. Louzguine-Luzgin, M.W. Chen, and J.H. Perepezko: Acta Mater., 2014, vol. 79, pp. 30–36.

M. Mohri, D. Wang, J. Ivanisenko, H. Gleiter, and H. Hahn: J. Alloys Compd., 2018, vol. 735, pp. 2197–2204.

S.H. Nandam, O. Adjaoud, R. Schwaiger, Y. Ivanisenko, M.R. Chellali, D. Wang, K. Albe, and H. Hahn: Acta Mater., 2020, vol. 193, pp. 252–60.

M. Mohri, M.R. Chellali, D. Wang, and J. Ivanisenko: Met. Mater. Int., 2021.

T. Li, K. Ma, and G. Zheng: J. Mater. Res., 2021, vol. 36, pp. 4951–62.

H. Gleiter: Small, 2016, vol. 12, pp. 2225–33.

N. Chen, D. Wang, T. Feng, R. Kruk, K.F. Yao, D.V. Louzguine-Luzgin, H. Hahn, and H. Gleiter: Nanoscale, 2015, vol. 7, pp. 6607–11.

S.H. Nandam, Y. Ivanisenko, R. Schwaiger, Z. Śniadecki, X. Mu, D. Wang, R. Chellali, T. Boll, A. Kilmametov, T. Bergfeldt, H. Gleiter, and H. Hahn: Acta Mater., 2017, vol. 136, pp. 181–89.

Z. Sniadecki, D. Wang, Y. Ivanisenko, V.S.K. Chakravadhanula, C. Kübel, H. Hahn, and H. Gleiter: Mater. Charact., 2016, vol. 113, pp. 26–33.

M. Mohri, D. Wang, J. Ivanisenko, H. Gleiter, and H. Hahn: Mater. Charact., 2017, vol. 131, pp. 140–47.

X.D. Wang, Q.P. Cao, J.Z. Jiang, H. Franz, J. Schroers, R.Z. Valiev, Y. Ivanisenko, H. Gleiter, and H.J. Fecht: Scr. Mater., 2011, vol. 64, pp. 81–84.

H. Shao, Y. Xu, B. Shi, C. Yu, H. Hahn, H. Gleiter, and J. Li: J. Alloys Compd., 2013, vol. 548, pp. 77–81.

C. Guo, Y. Fang, B. Wu, S. Lan, G. Peng, X.L. Wang, H. Hahn, H. Gleiter, and T. Feng: Mater. Res. Lett., 2017, vol. 5, pp. 293–99.

O. Franke, D. Leisen, H. Gleiter, and H. Hahn: J. Mater. Res., 2014, vol. 29, pp. 1210–16.

A. Sharma, S.H. Nandam, H. Hahn, and K.E. Prasad: Scr. Mater., 2021, vol. 191, pp. 17–22.

X.L. Wang, F. Jiang, H. Hahn, J. Li, H. Gleiter, J. Sun, and J.X. Fang: Scr. Mater., 2015, vol. 98, pp. 40–43.

K. Albe, Y. Ritter, and D. Şopu: Mech. Mater., 2013, vol. 67, pp. 94–103.

S. Adibi, P.S. Branicio, Y.W. Zhang, and S.P. Joshi: J. Appl. Phys., 2014, vol. 116, p. 043522.

S. Adibi, P.S. Branicio, and S.P. Joshi: Sci. Rep., 2015, vol. 5, p. 15611.

K. Zheng and P. Branicio: Phys. Rev. Mater., 2020, vol. 4, p. 076001.

C. Wang, D. Wang, X. Mu, S. Goel, T. Feng, Y. Ivanisenko, H. Hahn, and H. Gleiter: Mater. Lett., 2016, vol. 181, pp. 248–52.

X. Mu, L. Chen, R. Mikut, H. Hahn, and C. Kübel: Acta Mater., 2021, vol. 212, p. 116932.

J.X. Fang, U. Vainio, W. Puff, R. Würschum, X.L. Wang, D. Wang, M. Ghafari, F. Jiang, J. Sun, H. Hahn, and H. Gleiter: Nano Lett., 2012, vol. 12, pp. 458–63.

Y. Ritter, D. Opu, H. Gleiter, and K. Albe: Acta Mater., 2011, vol. 59, pp. 6588–93.

K. Zheng, S. Yuan, H. Hahn, and P.S. Branicio: Sci. Rep., 2021, vol. 11, p. 19246.

R. Witte, T. Feng, J.X. Fang, A. Fischer, M. Ghafari, R. Kruk, R.A. Brand, D. Wang, H. Hahn, and H. Gleiter: Appl. Phys. Lett., 2013, vol. 103, p. 073106.

C. Liu, E. Pineda, and D. Crespo: Metals, 2015, vol. 5, pp. 1073–1111.

E. Bonetti: Philos. Mag. B, 1987, vol. 56, p. 185.

H. Okumura, H.S. Chen, A. Inoue, and T. Masumoto: Jpn. J. Appl. Phys., 1991, vol. 30, pp. 2553–57.

Y. He and X. Li: Phys. Status Solidi, 1987, vol. 99, pp. 115–20.

X.-G. Li, Y. Zhang, and Y. He: J. Phys. Condens. Matter, 1990, vol. 2, pp. 809–16.

Q. Wang, S.T. Zhang, Y. Yang, Y.D. Dong, C.T. Liu, and J. Lu: Nat. Commun., 2015, vol. 6, p. 7876.

Y. Ueno, M. Hojo, H. Numakura, T. Ichitsubo, and J. Saida: Mater. Sci. Eng. A, 2009, vol. 521–522, pp. 232–35.

B. Cai, L.Y. Shang, P. Cui, and J. Eckert: Phys. Rev. B, 2004, vol. 70, p. 184208.

Q. Wang, J.M. Pelletier, Y. Da Dong, Y.F. Ji, and H. Xiu: Mater. Sci. Eng. A, 2004, vol. 379, pp. 197–203.

Z. Wang, D. Wang, P. Jiang, W. Wu, X. Li, F. Zu, and J. Shui: J. Wuhan Univ. Technol. Sci. Ed., 2017, vol. 32, pp. 1476–80.

M.A. Meyers and K.K. Chawla: Mechanical Behavior of Materials, 1999.

C.W. Macosko: Rheology: Principles, Measurements, and Applications, 1996.

A. Nowick and B.S. Berry: Anelastic Relaxation in Crystalline Solids, 1972.

N. Chen, D. Wang, P.F. Guan, H.Y. Bai, W.H. Wang, Z.J. Zhang, H. Hahn, and H. Gleiter: Appl. Phys. Lett., 2019, vol. 114, p. 043103.

T. Li, Y. Shen, and G. Zheng: Scr. Mater., 2021, vol. 203, p. 114109.

Acknowledgments

This work was supported by a grant from the Research Grants Council of the Hong Kong Special Administrative Region, China (PolyU152607/16E).

Data Availability

The datasets generated and/or analyzed during the current study are available from the corresponding author on reasonable request.

Conflict of interest

The authors have no conflicts of interest to declare that are relevant to the content of this article.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted March 23, 2022; accepted July 23, 2022.

Rights and permissions

About this article

Cite this article

Li, T., Zheng, G. The Anelastic Behaviors of Co–Fe–Ni–P Metallic Nano-glasses: Studies on the Viscous Glass–Glass Interfaces. Metall Mater Trans A 53, 3736–3748 (2022). https://doi.org/10.1007/s11661-022-06781-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-022-06781-4