Abstract

This study proposes a method for protecting 6061 aluminum alloy from corrosion fatigue. Corrosion fatigue can reduce fatigue strength at the endurance limit (108 cycles) from 55 pct yield tensile strength (YTS) to less than 30 pct YTS. This study revealed that anodizing and powder coating, which are commonly used in industry to prevent base metal corrosion, do not protect against damage from corrosion fatigue. Introduction of electrodeposition after anodizing was found to improve the resistance to corrosion fatigue. Electrodeposition increased the fatigue lives of anodized specimens in both ambient and corrosive environments.

Similar content being viewed by others

References

ASM International: ASM Handbook Volume 2 Properties and Selection: Nonferrous Alloys and Special -Purpose Materials, 2001.

J.R. Davis: Corrosion of Aluminum and Aluminum Alloys, ASM International, Materilas Park, 1999.

K. El-Menshawy, A.W.A. El-Sayed, M.E. El-Bedawy, H.A. Ahmed, and S.M. El-Raghy: Corros. Sci., 2012, vol. 54, pp. 167–73.

T. Minoda and H. Yoshida: Metall. Mater. Trans. A, 2002, vol. 33A, pp. 2891–98.

N. Zakerin and P. Najafisayar: J. Mater. Res. Technol., 2020, vol. 9, pp. 14990–15000.

G.M. Dominguez Almaraz, V.H. Mercado Lemus, and J. Jesús Villalon Lopez: Procedia Eng., 2010, vol. 2, pp. 805–13.

G.M. Dominguez Almaraz, V.H. Mercado Lemus, and J.J. Villalón López: in Supplemental Proceedings: Materials Fabrication, Properties, Characterization, and Modeling, 2011, vol. 2, pp. 643–50.

G.M.D. Almaraz, A.D. Aburto, and E.C. Gómez: Metall. Mater. Trans. A, 2014, vol. 45A, pp. 280–86.

Y. Takahashi, T. Shikama, S. Yoshihara, T. Aiura, and H. Noguchi: Acta Mater., 2012, vol. 60, pp. 2554–67.

Y. Takahashi, H. Yoshitake, R. Nakamichi, T. Wada, M. Takuma, T. Shikama, and H. Noguchi: Mater. Sci. Eng. A, 2014, vol. 614, pp. 243–49.

K. Chanyathunyaroj, S. Phetchcrai, G. Laungsopapun, and A. Rengsomboon: Int. J. Fatigue, 2020, vol. 133, p. 105420.

K. Morshed-Behbahani, P. Najafisayar, R. Hessam, and N. Zakerin: Metall. Mater. Trans. A, 2020, vol. 51A, pp. 5475–83.

I.C. Chung, C.K. Chung, and Y.K. Su: Surf. Coat. Technol., 2017, vol. 313, pp. 299–306.

H. Ashour Elkilany, M.A. Shoeib, and O.E. Abdel-Salam: Metallogr. Microstruct. Anal., 2019, vol. 8, pp. 861–70.

K.H. Rashid, A.A. Khadom, and H.B. Mahood: Met. Mater. Int., 2021, vol. 27, pp. 4059–73.

M. Franco, T.H. Krishna, A.M. Pillai, A. Rajendra, and A.K. Sharma: Acta Metall. Sin., 2013, vol. 26, pp. 647–56.

G. Sundararajan, N.P. Wasekar, and N. Ravi: Trans. Indian Inst. Met., 2010, vol. 63, pp. 203–08.

J.R. Davis: Aluminum and Aluminum Alloys, ASM International, Materials Park, 1993.

L. Telmenbayar, A.G. Ramu, D. Yang, M. Song, T.O. Erdenebat, and D. Choi: Surf. Coat. Technol., 2020, vol. 403, p. 126433.

J. Cabral-Miramontes, C. Gaona-Tiburcio, F. Estupinán-López, M. Lara-Banda, P. Zambrano-Robledo, D. Nieves-Mendoza, E. Maldonado-Bandala, J. Chacón-Nava, and F. Almeraya-Calderón: Coatings, 2020, vol. 10, p. 601.

M. Shahzad, M. Chaussumier, R. Chieragatti, C. Mabru, and F. Rezai-Aria: Mater. Des., 2011, vol. 32, pp. 3328–35.

C.A. José, C. Santos, and S. Gutierrez Ramón: Eng. Fail. Anal., 2018, vol. 90, pp. 82–89.

T.A. Misev and R. Van Der Linde: Prog. Org. Coat., 1998, vol. 34, pp. 160–68.

S.M. Mirabedini, G.E. Thompson, S. Moradian, and J.D. Scantlebury: Prog. Org. Coat., 2003, vol. 46, pp. 112–20.

J.B. Bajat, J.P. Popić, and V.B. Mišković-Stanković: Prog. Org. Coat., 2010, vol. 69, pp. 316–21.

K. Chanyathunyaroj, W. Samit, C. Poonthananiwatkul, and S. Phetchcrai: Trans. Indian Inst. Met., 2021, vol. 74, pp. 2135–47.

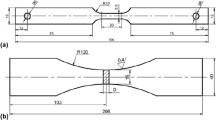

ASTM-B557M: Standard Test Methods for Tension Tesing Wrought and Cast Aluminum- and Magnesium-Alloy Products (Metric), 2015.

ASTM-E466: Standard Practice for Conducting Force Controlled Constant Amplitude Axial Fatigue Tests of Metallic Materials, 2015.

C.A. Grubbs: Met. Finish., 1999, vol. 97, pp. 476–93.

JIS H 8602: Combined Coatings of Anodic Oxide and Organic Coatings on Aluminium and Aluminium Alloys, 2016.

C.M. Sonsino: Int. J. Fatigue, 2007, vol. 29, pp. 2246–58.

C. Berger, B. Pyttel, and T. Trossmann: Int. J. Fatigue, 2006, vol. 28, pp. 1640–46.

C. Vargel: Corrosion of Aluminium, Elsevier, Amsterdam, 2020.

L. Xie, Q. Wang, M. Wang, X. Sheng, and Z. Li: J. Mater. Res., 2017, vol. 32, pp. 1105–17.

J.O. Park, C.H. Paik, Y.H. Huang, and R.C. Alkire: J. Electrochem. Soc., 1999, vol. 146, pp. 517–23.

G. Acosta and L. Veleva: Rev. Met., 2018, vol. 54, p. e134.

M.R. Bayoumi and A.K. Abdellatif: Eng. Fract. Mech., 1995, vol. 51, pp. 861–70.

M. Suraratchai, J. Limido, C. Mabru, and R. Chieragatti: Int. J. Fatigue, 2008, vol. 30, pp. 2119–26.

A. Almansour, M. Azizi, A.M. Jesri, and S. Entakly: Int. J. Acad. Sci. Res., 2015, vol. 3, pp. 37–45.

M. Shahzad, M. Chaussumier, R. Chieragatti, C. Mabru, and F. Rezai Aria: J. Mater. Process. Technol., 2010, vol. 210, pp. 1821–26.

M. Shahzad, M. Chaussumier, R. Chieragatti, C. Mabru, and F. Rezai Aria: Procedia Eng., 2010, vol. 2, pp. 1015–24.

J.S. Gandhi and W.J. Van Ooij: J. Mater. Eng. Perform., 2004, vol. 13, pp. 475–80.

Acknowledgments

This work was supported financially by the National Metal and Materials Technology Center (MTEC Grant No. P1951467). The authors would like to thank Thai Metal Aluminium Co., Ltd., for the specimen coating process and Dr. Julathep Kajornchaiyakul, Dr. Ruangdaj Tongsri, and Dr. John T.H. Pearce for their advice and encouragement throughout this work.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chanyathunyaroj, K., Moonrin, N., Laungsopapun, G. et al. Corrosion Fatigue Study of 6061 Aluminum Alloy: The Effect of Coatings on the Fatigue Characteristics. Metall Mater Trans A 53, 2874–2889 (2022). https://doi.org/10.1007/s11661-022-06712-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-022-06712-3