Abstract

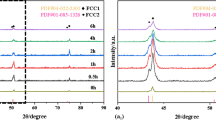

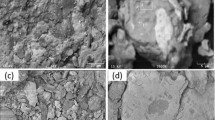

Thermal behavior investigation of CuNiCoZnAl high-entropy alloy powder produced by mechanical alloying indicated that a FCC single-phase solid solution transformed into two new phases at 500 °C. Despite this phase transformation, no indication of intermetallic compounds or amorphous phases was detected. Heat treatment of the high-entropy alloy was then carried out for 2 hours, and the nanocrystalline structure of heat-treated milled powder was retained up to 1000 °C. Besides, grain growth of CuNiCoZnAl high-entropy alloy powder at high homologous temperatures (> 0.6 Tm) was studied, and sluggish grain growth of the powder was observed clearly. Consolidation of the alloy powder was performed by spark plasma sintering at 800 °C, and a sample with porosity of 6.87 pct and density of 7.32 g cm−3 was achieved. Elastic moduli, Vickers microhardness, and fracture toughness of the bulk sample were measured as 186 ± 17 GPa, 599 ± 31 HV, and 4.45 MPa m0.5, respectively. The evaluation of wear behavior indicated that the dominant wear mechanism was adhesive wear. Moreover, tribochemical wear (oxidation) was found to be the minor wear mechanism. The present study revealed that CuNiCoZnAl high-entropy alloy has the potential to be used in many applications that high hardness and low elastic moduli are favorable.

Similar content being viewed by others

References

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, S.Y. Chang, Adv. Eng. Mater., 2004, vol. 6, pp. 299-303.

[2] N. Liu, W. Ding, X.J. Wang, C. Mu, J.J. Du, L.X. Liu, Metall. Mater. Trans. A, 2020, https://doi.org/10.1007/s11661-020-05751-y

A.S.M. Ang, Ch.C. Berndt, M.L. Sesso, A. Anupam, P.S.R.S. Kottada, B.S. Murty, Metall. Mater. Trans. A, 2015, vol. 46A, pp. 791-800.

[4] B.S. Murty, J.W. Ye, S. Ranganathan: High entropy alloys, 3rd ed, Elsevier, London, 2014.

X.W. Qiu, J. Alloys Compd., 2013, vol. 555, pp. 246-249.

S. Praveen, B.S. Murty, R.S. Kottada, Mater. Sci. Eng. A, 2012, vol. 534, pp. 83-89.

K.B. Zhang, Z.Y. Fu, J.Y. Zhang, J. Shi, W.M. Wang, Y. Wang, C. Wang, Q.J. Zhang, J. Alloys Compd, 2009, vol. 485, pp. L31-L34

[8] Z. Lyu, Ch. Lee, Sh.Y. Wang, X. Fan, J.W. Yeh, P.K. Liaw, Metall. Mater. Trans. A, 2018, https://doi.org/10.1007/s11661-018-4970-z.

I. Moravcik, J. Cizek, J. Zapletal, Z. Kovacova, J. Vesely, P. Minarik, M. Kitzmantel, E. Neubauer, I. Dlouhy, Mater. Des, 2017, vol. 119, pp. 141-150.

Z. Fu, W. Chen, H. Wen, D. Zhang, Z. Chen, B. Zheng, Y. Zhou, E.J. Lavernia, Acta. Mater, 2016, vol. 107, pp. 59-71.

L. M. Gouvea, I. Moravcik, M. Omasta, J. Vesely, J. Cizek, P. Minarik, J. Cupera, A. Zaděra, V. Jan, I. Dlouhy, Mater. Charact., 2020, vol. 159, pp. 110046.

[12] J. Miao, T. Guo, J. Ren, A. Zhang, B. Su, J. Meng, Vacuum. 2018 https://doi.org/10.1016/j.vacuum.2018.01.012.

S. Kumar, D. Kumar, O. Maulik, A.K. Pradhan, V. Kumar, A. Patniak, Metall. Mater. Trans. A, 2018, vol. 49A, pp. 5607–18.

S. Mridha, S. Samal, P.Y. Khan, K. Biswas, A. Govind, Metall. Mater. Trans. A, 2013, vol. 44A, pp. 4532-4541.

C.M. Liu, H.M. Wang, S.Q. Zhang, H.B. Tang, J. Alloys Compd, 2014, vol. 583, pp. 162-169

R. Sriharitha, B.S. Murty, R.S. Kottada, J. Alloys Compd, 2014, vol. 583, pp. 419-426.

S. Praveen, J. Basu, S. Kashyap, R.S. Kottada, J. Alloys Compd. 2016, vol. 662, pp. 361-367.

J. Cheng, D. Liu, X. Liang, B. Xu, Acta. Metall. Sin. Engl. Lett., 2014. vol. 6, pp. 27.

Z. Cai, X. Cui, Z. Liu, Y. Li, M. Dong, G. Jin, Opt. Laser. Tech, 2018, vol. 99, pp. 276-281.

L. Jiang, Y. Lu, W. Wu, Z. Cao, T. Li, J. Mater. Sci. Technol, 2016, vol. 32, pp. 245–250.

P. Wang, P. Cai, S. Zhou, L. Xu, J. Alloys Compd, 2017. vol. 695, pp. 462-475.

S. Varalakshmi, G.A. Rao, M. Kamaraj, B.S. Murty, J. Mater. Sci., 2010, vol. 45, pp. 5158-5163.

P.F. Yu, L.J. Zhang, H. Cheng, H. Zhang, M.Z. Ma, Y.C. Li, G. Li, P.K. Liaw, R.P. Liu, Intermetallics, 2016, vol. 70, pp. 82-87.

R.S. Ganji, P.S. Karthik, K.B.S. Rao, K.V. Rajulapati, Acta. Mater, 2017, vol. 125, pp. 58-68.

X. Liu, H. Cheng, Z. Li, H. Wang, F. Chang, W. Wang, Q. Tang, P. Dai, Vacuum, 2019, vol. 165, pp. 297–304.

H. Cheng, X. Liu, Q. Tang, W. Wang, X. Yan, P. Dai, J. Alloys Compd., 2019, vol. 775, pp. 742-751.

L.R. Kanyane, A. P. Popoola, N. Malatji, Results Phys., 2019, vol. 12, pp. 1754–1761.

P. Chauhan, S. Yebaji, V. N. Nadakuduru, T. Shanmugasundaram, J. Alloys Compd., 2020, 10.1016/j.jallcom.2019.153367.

A.I. Yurkova, V.V. Cherniavsky, V. Bolbut, M. Krüger, I. Bogomol, J. Alloys Compd., 2019, vol. 786, pp. 139-148.

Q. Liu, G. Wang, X. Sui, Y. Liu, X. Li, J. Yang, J. Mater. Sci. Technol., 2019, vol. 35, pp. 2600–2607.

F. Jiang, C. Zhao, D. Liang, W. Zhu, Y. Zhang, S. Pan, F. Ren, Mater. Sci. Eng. A, 2020, vol. 771, pp. 138625.

[32] P. Parameswaran, A.M. Rameshbabu, V. Vijayan, G.S. Kumar, C. Sakthivel, N. Pargunam, A.G. Antony, Metal. Powder. Report, 2019, https://doi.org/10.1016/j.mprp.2019.0

X. Ji, C. Ji, J. Cheng, Y. Shan, S. Tian, Wear, 2018, pp. 178–82.

Y. Yu, J. Wang, J. Li, J. Yang, H. Kou, W. Liu, J. Mater. Sci. Technol., 2016, vol. 32, pp. 470–476.

S. Varalakshmi, M. Kamaraj, B.S. Murty, Metall. Mater. Trans. A, 2010, vol. 41A, pp. 2703-2709.

S. Mohanty, N.P. Gurao, K. Biswas, Mater. Sci. Eng. A, 2014, vol. 617, pp. 211-218.

F. Salemi, M.H. Abbasi, F. Karimzadeh, J. Alloys Compd., 2016, vol. 685, pp. 278-286.

C.B. Ponton, R.D. Rawlings, Mater. Sci. Technol., 1989, vol. 5, pp. 865-872.

[39] P.J. Blau: ASM handbook of Friction, Lubrication and Wear Technology, ASM International, Novelty, 1992.

[40] B.D. Cullity: Stock SR, Elements of X-ray diffraction, third ed, Pearson, Upper Saddle River, 2001.

[41] D.R. Lide: Handbook of chemistry and physics, 84th ed, CRC, New York, 2004.

H. Celik, E. Aldirmaz, I. Aksoy, GUJ Sci., 2012, vol. 25, pp. 337-342.

[43] M. Wagner: Thermal analysis in practice: fundamentals aspects, Hanser, Munich, 2018.

Y.X. Zhuang, H.D. Xue, Z.Y. Chen, Z.Y. Hu, J.C. He, Mater. Sci. Eng. A, 2013, vol. 572, pp. 30-35.

Z. Fu, W. Chen, H. Xiao, L. Zhou, D. Zhu, S. Yang, Mater. Des, 2013, vol. 44, pp. 535-539.

S. Fang, W. Chen, Zh. Fu, Mater. Des., 2014, vol. 54, pp. 973-979.

B. Niu, W. Ji, N. Li, F. Zhang, Y. Wu, Mater. Sci. Technol., 2016, vol. 32, pp. 94-98.

H. Prasad, S. Singh, B.B. Panigrahi, J. Alloys Compd., 2017, vol. 692, pp. 720-726.

O. Maulik, D. Kumar, S. Kumar, D.M. Fabijanic, V. Kumar, Intermetallics, 2016, vol. 77, pp. 46-56.

N.T.B.N. Koundinya, C.S. Babu, K. Sivaprasad, P. Susila, N.K. Babu, J. Baburao, J. Mater. Eng. Perform., 2013, vol. 22, pp 3077-3084.

C. Suryanarayana, Prog. Mater Sci., 2001, vol. 46, pp. 1-184.

H.F. Sheng, M. Gong, L.M. Peng, Mater. Sci. Eng. A, 2013, vol. 567, pp. 14-20.

Z.P. Lu, H. Wang, M.W. Chen, I. Baker, J.W. Yeh, C.T. Liu, T.G. Nieh, Intermetallics, 2015, vol. 66, pp. 67-76.

C. Sajithbabu, N.T.B.N. Koundinya, K. Sivaprasad, J.A. Szpunar, Procedia. Mater. Sci., 2014, vol. 6, pp. 641-647.

C. Sajithbabu, K. Sivaprasad, V. Muthupandi, J.A. Szpunar, Procedia Mater. Sci, 2014, vol. 5, pp. 1020-1026.

R.S. Ganji, K.V. Rajulapati, K.B.S. Rao, Trans. Indian Inst. Met. 2020. 10.1007/s12666-020-01875-2

[57] W. Luo, Y. Liu, Y. Luo, M. Wu, J. Alloys Compd, 2018, https://doi.org/10.1016/j.jallcom.2018.04.270.

A. Zhang, J. Han, J. Meng, B. Su, P. Li, Mater. Lett., 2016, vol. 181, pp. 82–85.

[59] H. Baker: ASM handbook of properties and selection: nonferrous alloys and special-purpose materials, Cleveland, ASM International, 1990.

Z. Fu, W. Chen, S. Fang, D. Zhang, H. Xiao, D. Zhu, J. Alloys Compd., 2013, vol. 553, pp. 316-323.

K.B. Zhang, Z.Y. Fu, J.Y. Zhang, W.M. Wang, S.W. Lee, K. Niihara, J. Alloys Compd, 2010, vol. 495, pp. 33-38.

X.W. Qiu, C.X. Huang, M.J. Wu, C.G. Liu, Y.P. Zhang, J. Alloys Compd, 2016, vol. 658, pp. 1-5.

H. Khanchandani, P. Sharma, R. Kumar, O. Maulik, V. Kumar, Adv. Powder Technol, 2016, vol. 27, pp. 289-294.

Y. Yu, J. Wang, J. Li, J. Yang, H. Kou, W. Liu, J. Mater. Sci. Technol., 2016, vol. 32, pp. 470-476.

B. Zahmatkesh, M.H. Enayati, F. Karimzadeh, Mater. Des, 2010, vol. 31, pp. 4891-4896.

[66] J. Takadoum: Materials and surface engineering in tribology pp. 1-89, John Wiley, New York, 2008.

Y. Mazaheri, F. Karimzadeh, M.H. Enayati, J. Mater. Sci. Technol., 2013, vol. 29, pp. 813-820.

D.Y. Lin, N.N. Zhang, B. He, G.W. Zhang, Y. Zhang, D.Y. Li, J. Iron. Steel. Res. Int., 2017, vol. 24, pp. 184-189.

Z. Yazdani, F. Karimzadeh, M.H. Abbasi, A. Amini, Trans. Indian. Inst. Met., 2015, vol. 68, pp. 927-934.

H. Ait-Sadi, L. Hemmouche, L. Hattali, M. Britah, A. Iost, N. Mesrati, Tribology. Int., 2015, vol. 90, pp. 372-385.

H.F. Sun, C.M. Wang, X. Zhang, R.Z. Li, L.Y. Ruan, Mater. Res. Innov., 2015, vol. 19, pp. 89-93.

M. Jafari, M.H. Enayati, M.H. Abbasi, F. Karimzadeh, Mater. Des, 2010, vol. 31, pp. 663-669.

C. Huang, Y.Z. Tang, Y.Z. Zhang, A.P. Dong, J. Tu, L.J. Chai, Z.M. Zhou, Rare Met., 2017, pp. 1–7.

E. MohammadSharifi, F. Karimzadeh, M.H. Enayati, Mater. Des., 2011, vol. 32, pp. 3263-3271.

L. Jiang, W. Wu, Z. Cao, D. Deng, T. Li, J. Therm. Spray Technol., 2016, vol. 25, pp. 806-814.

Conflict of interest

No potential conflict of interest was reported by the authors.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted March 30, 2020; accepted February 14, 2021.

Rights and permissions

About this article

Cite this article

Salemi, F., Karimzadeh, F. & Abbasi, M.H. Evaluation of Thermal and Mechanical Behavior of CuNiCoZnAl High-Entropy Alloy Fabricated Using Mechanical Alloying and Spark Plasma Sintering. Metall Mater Trans A 52, 1947–1962 (2021). https://doi.org/10.1007/s11661-021-06205-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-021-06205-9