Abstract

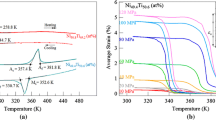

Uranium-6 wt pct niobium (14 at pct niobium) displays the shape memory effect (SME), where deformation proceeds by twinning and twin rearrangement via boundary migration within the SME regime. In-situ neutron diffraction during deformation suggests that after SME strain is exhausted, deformation proceeds via another twinning mechanism that does not recover to the original parent orientation upon reheating and transformation. Here we show from in-situ tensile and compressive loading and unloading experiments that early post-SME twins partially reverse during unloading, which is evident by rapid texture evolution, and this reversion is responsible for the inelastic portion of the previously reported ~ 2 pct strain recovery.

Similar content being viewed by others

Notes

The rotation for the (010) vs the (100) twin differs by only ~5 deg, too small to be differentiated by the texture data. Therefore, the twin will be henceforth referred to as (010), with the understanding that either it or its reciprocal could be responsible for the observed rotation.[11]

In both the tension and compression curves, there is a lowering of the work hardening rate (WHR), which is often referred to in the literature as a plateau, even though the WHR does not go to zero.

References

[1] R.J. Jackson, Rocky Flats Division, The Dow Chemical Company, Golden, Colorado, 1970.

[2] R.A. Vandermeer, J.C. Ogle, W.B. Snyder, Scr. Metall., 1978, vol. 12, pp. 243-248.

[3] R.A. Vandermeer, J.C. Ogle, W.G. Northcutt, Metall. Trans. A, 1981, vol. 12, pp. 733-741.

[4] D.W. Brown, M.A.M. Bourke, P.S. Dunn, R.D. Field, M.G. Stout, D.J. Thoma, Metall. Mater. Trans. A, 2001, vol. 32A, pp. 2219-2228.

[5] R.A. Vandermeer, Acta Metall., 1980, vol. 28, pp. 383-393.

[6] D.A. Carpenter, R.A. Vandermeer, Adv. X-Ray Anal., 1985, vol. 26, pp. 307-312.

[7] R.D. Field, D.W. Brown, D.J. Thoma, Phil. Mag., 2005, vol. 85, pp. 1441-1457.

[8] R.D. Field, D.W. Brown, D.J. Thoma, Phil. Mag., 2005, vol. 85, pp. 2593-2609.

[9] R.D. Field, D.J. Thoma, P.S. Dunn, D.W. Brown, C.M. Cady, Phil. Mag. A, 2001, vol. 81, pp. 1691-1724.

[10] D.W. Brown, M.A.M. Bourke, A.J. Clarke, R.D. Field, R.E. Hackenberg, W.L. Hults, D.J. Thoma, J. Nuc. Matl., 2016, vol. 481, pp. 164-175.

[11] C.N. Tupper, D.W. Brown, R.D. Field, T.A. Sisneros, B. Clausen, Metall. Mater. Trans. A, 2012, vol. 43A, pp. 520-530.

[12] D.W. Brown, M.A.M. Bourke, P.S. Dunn, R.D. Field, M.G. Stout, D.F. Teter, D.J. Thoma, S.C. Vogel, in: S. Bhatia, P. Khalifah, D. Pochan, P. Radaelli (Eds.) Materials Research Society Fall Meeting, Materials Research Society, Boston, MA, 2005, pp. 205-210.

[13] A.J. Clarke, R.D. Field, R.J. McCabe, C.M. Cady, R.E. Hackenberg, D.J. Thoma, Acta Mater., 2008, vol. 56, pp. 2638-2648.

[14] A.J. Clarke, R.D. Field, P.O. Dickerson, R.J. McCabe, J.G. Swadener, R.E. Hackenberg, D.J. Thoma, Scr. Mater., 2009, vol. 60, pp. 890-892.

[15] Y. Zhang, X. Wang, X. Chen, D. Xiao, Rare Metal Materials and Engineering, 2015, vol. 44, pp. 1094-1098.

[16] Z.Y. Ren, R. Ma, G.C. Hu, J. Wu, Z.H. Wang, C. Luo, J. Nuc. Matl., 2017, vol. 494, pp. 72-78.

[17] Y.Z. Zhang, D.P. Wang, W.J. Guan, X.L. Chen, X.L. Wang, Powder Diffr., 2017, vol. 32, pp. 72-77.

[18] M.A.M. Bourke, D.C. Dunand, E. Ustundag, Appl. Phys. A, 2002, vol. A74, pp. S1707-S1709.

[19] R.B. Vondreele, J.D. Jorgensen, C.G. Windsor, J. App. Crys., 1982, vol. 15, pp. 581-589.

[20] R.B. Von Dreele, J. App. Crys., 1997, vol. 30, pp. 517-525.

B. Clausen, Los Alamos National Lab, Los Alamos, NM, 2004.

[22] P.W. Stephens, J. App. Crys., 1999, vol. 32, pp. 281-289.

[23] B.A. Hatt, J. Nuc. Matl., 1966, vol. 19, pp. 133-141.

B. Clausen, PhD. Technical University of Denmark, 1997.

[25] S.R. MacEwen, J. Faber, A.P.L. Turner, Acta Metall., 1983, vol. 31, pp. 657-676.

[26] M.R. Daymond, M.A.M. Bourke, R.B. Von Dreele, B. Clausen, T. Lorentzen, J. App. Phys., 1997, vol. 82, pp. 1554-1562.

[27] D.W. Brown, S.P. Abeln, W.R. Blumenthal, M.A.M. Bourke, M.C. Mataya, C.N. Tome, Metall. Mater. Trans. A, 2005, vol. 36A, pp. 929-939.

[28] M.R. Daymond, C.N. Tome, M.A.M. Bourke, Acta Mater., 2000, vol. 48, pp. 553-564.

[29] S.R. Agnew, D.W. Brown, C.N. Tome, Acta Mater., 2006, vol. 54, pp. 4841-4852.

[30] R.E. Stoller, S.J. Zinkle, J. Nuc. Matl., 2000, vol. 283, pp. 349-352.

Acknowledgments

This work was supported by the US Department of Energy through the Los Alamos National Laboratory and benefited from the use of the Lujan Neutron Scattering Center at LANSCE, LANL. Los Alamos National Laboratory is operated by Triad National Security, LLC, for the National Nuclear Security Administration of U.S. Department of Energy (Contract No. 89233218CNA000001). AJC acknowledges support by the Center for Advanced Non-Ferrous Structural Alloys (CANFSA), a National Science Foundation Industry/University Cooperative Research Center (I/UCRC) [Award No. 1624836], at the Colorado School of Mines and Iowa State University during the preparation of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted April 27, 2019.

Rights and permissions

About this article

Cite this article

Clarke, A.J., Brown, D.W., Clausen, B. et al. Reversion of Post-Shape Memory Effect Twins During Unloading of Uranium-6 wt pct Niobium. Metall Mater Trans A 51, 1614–1624 (2020). https://doi.org/10.1007/s11661-020-05647-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-05647-x