Abstract

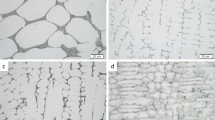

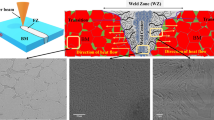

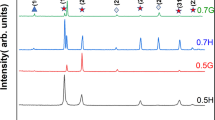

Weld solidification and weldability of AlxCoCrCuyFeNi high-entropy alloys (HEA) were characterized as a function of Al and Cu molar ratio in the alloy composition. Autogenous gas tungsten arc welding (GTAW) was performed on the as-melted ingots. Fusion zone and heat-affected zone microstructures were investigated using optical and electron microscopy, and compared to thermodynamic CALPHAD-based calculations. Weld cracking susceptibility was compared to cast pin tear test (CPTT) results. It was found that strong Cu segregation on solidification promotes hot cracking in fusion welds on AlCoCrCuyFeNi alloys (y > 0.1). Cu-rich liquid forms during the final stages of solidification and facilitates solidification cracking in the fusion zone. The Cu-rich interdendritic readily remelts during reheating and promotes liquation cracking in the heat-affected zone. The cracking mechanisms in the welds change to brittle intergranular cracking in low and no Cu alloy compositions due to a high-hardness BCC microstructure (> 500 HV). Lowering the Al molar ratio in AlxCoCrCu0.1FeNi alloys (x ≤ 0.5) mitigates brittle cracking by promoting FCC solidification structure.

Similar content being viewed by others

Change history

31 July 2020

The Acknowledgments in the original article are incomplete. Following is the updated text.

References

[1] J.-W. Yeh, S.-K. Chen, S.-J. Lin, J.-Y. Gan, T.-S. Chin, T.-T. Shun, C.-H. Tsau, and S.-Y. Chang: Adv. Eng. Mater., 2004, vol. 6, pp. 299–303.

[2] M.-H. Tsai and J.-W. Yeh: Mater. Res. Lett., 2014, vol. 2, pp. 107–23.

[3] D.B. Miracle and O.N. Senkov: Acta Mater., 2017, vol. 122, pp. 448–511.

[4] W.-R. Wang, W.-L. Wang, and J.-W. Yeh: J. Alloys Compd., 2014, vol. 589, pp. 143–52.

[5] C.-J. Tong, M.-R. Chen, J.-W. Yeh, S.-J. Lin, S.-K. Chen, T.-T. Shun, and S.-Y. Chang: Metall. Mater. Trans. A, 2005, vol. 36, pp. 1263–71.

[6] W.-R. Wang, W.-L. Wang, S.-C. Wang, Y.-C. Tsai, C.-H. Lai, and J.-W. Yeh: Intermetallics, 2012, vol. 26, pp. 44–51.

[7] C.-J. Tong, Y.-L. Chen, J.-W. Yeh, S.-J. Lin, S.-K. Chen, T.-T. Shun, C.-H. Tsau, and S.-Y. Chang: Metall. Mater. Trans. A, 2005, vol. 36, pp. 881–93.

[8] C.-C. Tung, J.-W. Yeh, T. Shun, S.-K. Chen, Y.-S. Huang, and H.-C. Chen: Mater. Lett., 2007, vol. 61, pp. 1–5.

[9] Y.-F. Kao, T.-J. Chen, S.-K. Chen, and J.-W. Yeh: J. Alloys Compd., 2009, vol. 488, pp. 57–64.

[10] C.-M. Lin and H.-L. Tsai: Intermetallics, 2011, vol. 19, pp. 288–94.

[11] S. Singh, N. Wanderka, B.S. Murty, U. Glatzel, and J. Banhart: Acta Mater., 2011, vol. 59, pp. 182–90.

M. Nahmany, Z. Hooper, A. Stern, V. Geanta, and I. Voiculescu: Metallogr., Microstruct., Anal., 2016, vol. 5, pp. 229–40.

[13] T. Yue, H. Xie, X. Lin, H. Yang, and G. Meng: Entropy, 2013, vol. 15, pp. 2833–45.

[14] T.M. Yue, H. Xie, X. Lin, H.O. Yang, and G.H. Meng: J. Alloys Compd., 2014, vol. 587, pp. 588–93.

[15] B.A. Welk, R.E.A. Williams, G.B. Viswanathan, M.A. Gibson, P.K. Liaw, and H.L. Fraser: Ultramicroscopy, 2013, vol. 134, pp. 193–9.

[16] A.C. Martin and C. Fink: Weld. World, 2019, vol. 63, pp. 739–50.

[17] K. Poorhaydari, B.M. Patchett, and D.G. Ivey: Weld. J., 2005, vol. 84, pp. 149s–155s.

[18] B.T. Alexandrov and J.C. Lippold: Weld. World, 2013, vol. 57, pp. 635–48.

G. Vander-Voort and E. Manilova: Microsc. Microanal., 2004, vol. 10, pp. 690–1.

[20] J.M. Sosa, D.E. Huber, B. Welk, and H.L. Fraser: Integrating Materials, 2014, vol. 3, pp. 123-40.

Acknowledgments

This work was supported by the Institute of Materials Research (IMR) at The Ohio State University, and by the American Welding Society (AWS) Foundation. The authors express their gratitude to Brady Soulivong, high school intern in the Welding Engineering Program at The Ohio State University. Electron microscopy was performed at the Center for Electron Microscopy and Analysis (CEMAS) at The Ohio State University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted June 26, 2019.

Rights and permissions

About this article

Cite this article

Martin, A.C., Oliveira, J.P. & Fink, C. Elemental Effects on Weld Cracking Susceptibility in AlxCoCrCuyFeNi High-Entropy Alloy. Metall Mater Trans A 51, 778–787 (2020). https://doi.org/10.1007/s11661-019-05564-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05564-8