Abstract

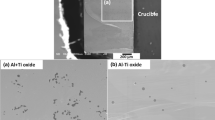

Ti-bearing oxide inclusions are utilized to enhance the properties of steel used in shipbuilding, multi-purpose gas carriers, and pipelines in accordance with the principles of oxide metallurgy. Conventionally, Ti-bearing oxide inclusions have been assumed to be stable during isothermal holding. The authors propose the possibility of modifying Ti-bearing oxide inclusions by appropriate heat treatment. To provide fundamental information on the evolution of Ti-bearing inclusions in solid steel during isothermal holding, the effect of the isothermal holding time on their evolution at 1573 K (1300 °C) was studied systematically. For heterogeneous phase Al+Ti oxide in the as-cast alloys, the composition and size distribution were maintained during isothermal holding. In contrast, homogeneous phase Al-Ti oxide in the as-cast alloys changed to a heterogeneous oxide consisting of an Al-rich part and a Ti-rich part and its shape changed from spherical to irregular. The composition of the Al-Ti oxide changed upon isothermal holding for 0.5 hour, and it occurred earlier in the Al-Ti oxide with a higher Al content. The evolution mechanism is considered to involve the precipitation of Al2O3 from the Al-Ti oxide owing to crystallization of glassy oxide during isothermal holding. The results challenge the long-held opinion that Ti-bearing oxide inclusions are maintained in solid steel during isothermal holding, which is the first step toward modifying oxide inclusions by heat treatment as a new concept in oxide metallurgy.

Similar content being viewed by others

References

D. Zhang, H. Terasaki, and Y. Komizo: Acta Materialia, 2010, 58, 1369-1378.

Y. Hou, W. Zheng, Z. Wu, G. Li, N. Moelans, M. Guo, and B. S. Khan: Acta Materialia, 2016, 118, 8-16.

J. Shim, Y. Suh, Y. Cho, J. Shim, J. Byun, and D. Lee: Acta Materialia, 2001, 49, 2115-2122.

J. M. Gregg, and H. K. D. Bhadeshia: Acta Materialia, 1997, 45, 739-748.

J. Byun, J. Shim, Y. Cho, and D. Lee: Acta Materialia, 2003, 51, 1593-1606.

J. Shim, Y. Cho, S. Chung, J. Shim, and D. Lee: Acta Materialia, 1999, 47, 2751-2760.

H. Mabuchi, R. Uemori, and M. Fujioka: ISIJ Int., 1996, 36, 1406-1412.

J. L. Lee, and Y. T. Pan: ISIJ Int., 1995, 35, 1027-1033.

Y. Kang, J. Jang, J. Park, and C. Lee: Met. Mater. Int., 2014, 1, 119-127.

Y. Li, J. Liu, Y. Deng, X. Han, W. Hu, and C. Zhong: Journal of Alloys and Compounds, 2016, 673, 28-37.

Takahashi T, Sakae T, Yoshida T (1967) Tetsu-to-Hagané 53:342-49.

K. Takano, R. Nakao, S. Fukuoto, T. Tsutiyama, and S. Takaki: Tetsu-to-Hagané, 2003, 89, 616-622.

H. Shibata, T. Tanaka, K. Kimura, and S. Kitamura: Ironmaking Steelmaking, 2010, 37, 522-528.

Y. Ren, L. Zhang, and P.C. Pistorius: Metall. Mater. Trans. B, 2017, 48, 2281-2292.

H. Shibata, K. Kimura, T. Tanaka, and S. Kitamura: ISIJ Int., 2011, 51, 1944-1950.

K. Kim, S.J. Kim, H. Shibata, and S. Kitamura: ISIJ Int., 2014, 54, 2144-2153.

K. Kim, H. Shibata, and S. Kitamura: ISIJ Int., 2014, 54, 2678-2686.

C. Liu, K. Kim, S. Kim, J. Li, S. Ueda, X. Gao, H. Shibata, and S. Kitamura: Metall. Mater. Trans. B, 2015, 46, 1875-1884.

C. Liu, S. Yang, J. Li, H. Ni, and X. Zhang: Metall. Mater. Trans. B, 2017, 48, 1348-1357.

F. Ruby-Meyer, J. Lehmann, and H. Gaye: Scand. J. Metall., 2000, 29, 206-212.

I. Jung, S. A. Decterov, and A. D. Pelton: ISIJ Int., 2004, 44, 527-536.

I. Jung, G. Eriksson, P. Wu, and A. D. Pelton: ISIJ Int., 2009, 49, 1290-1297.

Y. Kang, and J. Lee: ISIJ Int., 2017, 57, 1665-1667.

H. Matsuura, C. Wang, G. H. Wen, and S. Sridhar: ISIJ Int., 2007, 47, 1265-1274.

C. Wang, N. T. Nufher, and S. Sridhar: Metall. Mater. Trans. B, 2009, 40, 1005-1021.

C. Wang, N. T. Nufher, and S. Sridhar: Metall. Mater. Trans. B, 2009, 40, 1022-1034.

C. Wang, N. T. Nufher, and S. Sridhar: Metall. Mater. Trans. B, 2010, 41, 1084-1094.

C. Wang, N. Verma, Y. Kwon, W. Tiekink, N. Kikuchi, and S. Sridhar: ISIJ Int., 2011, 51, 375-381.

M. Li, H. Matsuura, and F. Tsukihashi: Metall. Mater. Trans. B, 2017, 48, 1915-1923.

M. Nagano, S. Nagashima, H. Maeda, and A. Kato: Ceramics Int., 1999, 25, 681-687.

C. Xuan, A. V. Karasev, and P. G. Jönsson,: ISIJ Int., 2016, 56, 1204-1209.

C. Xuan, A. V. Karasev, P. G. Jönsson, and K. Nakajima: Steel Research Int., 2017, 88, 262-270.

K. Nakajima: Tetsu-to-Hagané, 1994, 80, 383-388.

M. Humenik, and W. D. Kingery: J. Am. Ceram. Soc., 1954, 37, 18-23.

H. Ito, M. Hino, and S. Ban-ya: Tetsu-to-Hagané, 1997, 83, 773-778.

W. Y. Cha, T. Miki, Y. Sasaki, and M. Hino: ISIJ Int., 2008, 48, 729-738.

K. Yamamoto, T. Hasegawa, and J. Takamura: Tetsu-to-Hagané, 1993, 79, 1169-1175.

Y. Kang and H. Lee: ISIJ Int., 2010, 50, 501-508.

M. Jiang, X. H. Wang, Z. Y Hu, K. P. Wang, C. W. Yang, and S. R. Li: Materials Characterization, 2015, 108, 58-67.

Q. Huang, X. Wang, M. Jiang, Z.Hu, and C. Yang: Steel Research Int., 2015, 87, 445-455.

Z. Yang, F. Wang, S. Wang, and B. Song: Steel Research. Int., 2008, 79, 390-395.

Acknowledgments

The authors would like to thank Professor Xiaojun Hu and Dr. Huijing Cheng in the State Key Laboratory of Advanced Metallurgy, University of Science and Technology Beijing for their assistance in the analysis by automatic SEM-EDS.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted June 26, 2018.

Rights and permissions

About this article

Cite this article

Li, M., Matsuura, H. & Tsukihashi, F. Time-Dependent Evolution of Ti-Bearing Oxide Inclusions During Isothermal Holding at 1573 K (1300 °C). Metall Mater Trans A 50, 863–873 (2019). https://doi.org/10.1007/s11661-018-5015-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-018-5015-3