Abstract

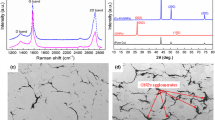

Copper/graphene nanoplatelet (GNP) nanocomposites were produced by a wet mixing method followed by a classical powder metallurgy technique. A qualitative evaluation of the structure of graphene after mixing indicated that wet mixing is an appropriate dispersion method. Thereafter, the effects of two post-processing techniques such as repressing–annealing and hot isostatic pressing (HIP) on density, interfacial bonding, hardness, and thermal and electrical conductivity of the nanocomposites were analyzed. Density evaluations showed that the relative density of specimens increased after the post-processing steps so that after HIPing almost full densification was achieved. The Vickers hardness of specimens increased considerably after the post-processing techniques. The thermal conductivity of pure copper was very low in the case of the as-sintered samples containing 2 to 3 pct porosity and increased considerably to a maximum value in the case of HIPed samples which contained only 0.1 to 0.2 pct porosity. Electrical conductivity measurements showed that by increasing the graphene content electrical conductivity decreased.

Similar content being viewed by others

References

H. Du, D. Lu, J. Qi, Y. Shen, L. Yin, Y. Wang, Z. Zheng, and T. Xiong. (2014) Heat dissipation performance of porous copper with elongated cylindrical pores. J. Mater. Sci. Technol. 30:934–938.

J. Kováčik and Š. Emmer, “Thermal expansion of Cu/graphite composites : effect of copper coating,” Kov. Mater. 49, 411–416 (2011).

B. Chen, Q. Bi, J. Yang, Y. Xia, and J. Hao, “Tribology International Tribological properties of solid lubricants (graphite, h-BN) for Cu-based P/M friction composites,” Tribol. Int. 41, 1145–1152 (2008).

A. Saboori, M. Pavese, C. Badini, and P. Fino (2017) Microstructure and thermal conductivity of Al-Graphene composites fabricated by powder metallurgy and hot rolling techniques. Acta Metall. Sin. 30:675–687.

M. Rashad, F. Pan, Y. Liu, X. Chen, and H. Lin. (2016) High temperature formability of graphene nanoplatelets-AZ31 composites fabricated by stir-casting method. J. Magnes. Alloy. 4:270–277.

A. Saboori, M. Pavese, C. Badini, and P. Fino (2017) A novel Cu–GNPs nanocomposite with improved thermal and mechanical properties. Acta Metall. Sin. https://doi.org/10.1007/s40195-017-0643-y.

M. Rashad, F. Pan, H. Hu, M. Asif, S. Hussain, and J. She. (2015) Enhanced tensile properties of magnesium composites reinforced with graphene nanoplatelets,” Mater. Sci. Eng. A 630, 36–44.

JR Davis (2001) Powder metallurgy: copper and copper alloys. In JR Davis (ed.) ASM Specialty Handbook. ASM International, Materials park.

R. N. Caron, Copper Alloys: Properties and Applications, Encycl. Mater. Sci. Technol., 2nd ed. (2001).

K. J. A. Kundig and J. G. Cowie., Mechanical Engineers’ Handbook : Materials and Mechanical Design, 3rd ed., M. Kutz, Ed. (John Wiley & Sons, Inc., 2006).

T. Varol and A. Canakci, “Microstructure, Electrical Conductivity and Hardness of Multilayer Graphene/Copper Nanocomposites Synthesized by Flake Powder Metallurgy,” Met. Mater. Int. 21, 704–712 (2015).

T. Varol and A. Canakci, “The effect of type and ratio of reinforcement on the synthesis and characterization Cu-based nanocomposites by flake powder metallurgy,” J. Alloys Compd. 649, 1066–1074 (2015).

M. Rashad, F. Pan, M. Asif, and A. Tang, “Powder metallurgy of Mg–1%Al–1%Sn alloy reinforced with low content of graphene nanoplatelets (GNPs),” J. Ind. Eng. Chem. 20, 4250–4255 (2014).

L. Liu, M. Qing, Y. Wang, and S. Chen (2015) Defects in Graphene : Generation, Healing, and Their Effects on the Properties of Graphene : A Review,” J. Mater. Sci. Technol. 31, 599–606.

M. Rashad, F. Pan, A. Tang, M. Asif, S. Hussain, J. Gou, and J. Mao (2015)Improved strength and ductility of magnesium with addition of aluminum and graphene nanoplatelets (Al + GNPs) using semi powder metallurgy method. J. Ind. Eng. Chem. 23, 243–250.

A. Saboori, C. Novara, M. Pavese, C. Badini, F. Giorgis, and P. Fino (2017)An Investigation on the Sinterability and the Compaction Behavior of Aluminum/Graphene Nanoplatelets (GNPs) Prepared by Powder Metallurgy. J. Mater. Eng. Perform. 26, 993–999.

A. C. Ferrari and J. Robertson, “Resonant Raman spectroscopy of disordered, amorphous, and diamondlike carbon,” Phys. Rev. B 64, 1–13 (2001).

T. M. G. Mohiuddin, A. Lombardo, R. R. Nair, A. Bonetti, G. Savini, R. Jalil, N. Bonini, D. M. Basko, C. Galiotis, et al., “Uniaxial strain in graphene by Raman spectroscopy : G peak splitting, Grüneisen parameters, and sample orientation,” Phys. Rev. B 79, 1–8 (2009).

R. Perez-Bustamante, D. Bolanos-Morales, J. Bonilla-Maetinez, and I. Estrada-Guel, “Microstructural and hardness behavior of graphene-nanoplatelets/aluminum composites synthesized by mechanical alloying,” J. Alloy. compd. 615, S578–S582 (2014).

R. Pérez-Bustamante, C. D. Gómez-Esparza, I. Estrada-Guel, M. Miki-Yoshida, L. Licea-Jiménez, S. A. Pérez-García, and R. Martínez-Sánchez, “Microstructural and mechanical characterization of Al–MWCNT composites produced by mechanical milling,” Mater.Sci. Eng. A 502, 159–163 (2009).

M. Tabandeh-khorshid, J. B. Ferguson, B. F. Schultz, C. Kim, K. Cho, and P. K. Rohatgi (2016) Strengthening mechanisms of graphene- and Al2O3 -reinforced aluminum nanocomposites synthesized by room temperature milling. Mater. Des. 92, 79–87.

K. Chu and C. C. Jia, “Enhanced strength in bulk graphene-copper composite,” Phys. Status Solidi A 211, 184–190 (2014).

F. Akhtar, S. Javid, K. Ali, X. Du, and S. Guo, “Microstructure, mechanical properties, electrical conductivity and wear behavior of high volume TiC reinforced Cu-matrix composites,” Mater. Charact. 60, 327–336 (2009).

K. Rajkumar and S. Aravindan, “Tribological behavior of microwave processed copper – nanographite composites,” Tribiology Int. 57, 282–296 (2013).

F. Chen, J. Ying, Y. Wang, S. Du, Z. Liu, and Q. Huang (2016) Effects of graphene content on the microstructure and properties of copper matrix composites. Carbon N. Y. 96, 836–842.

P. Goli, H. Ning, X. Li, C. Y. Lu, K. S. Novoselov, and A. A. Balandin, “Thermal properties of graphene–copper–graphene heterogeneous films,” NANO Lett. 14, 1497–1503 (2014).

J. P. Tu, W. Rong, S. Y. Guo, and Y. Z. Yang, “Dry sliding wear behavior of in situ Cu – TiB 2 nanocomposites against medium carbon steel against medium carbon steel,” Wear 255, 832–835 (2003).

A. Nadkarani: Dispersion strengthened metal composites. U.S. Patent No. 4,752,334. 1988.

T. Varol and A. Canakci, “Effect of the CNT Content on Microstructure, Physical and Mechanical Properties of Cu-Based Electrical Contact Materials Produced by Flake Powder Metallurgy,” Arab. J. Sci. Eng. 40, 2711–2720 (2015).

Claire Arnaud, Florence Lecouturier, David Mesguich, Nelson Ferreira,Geoffroy Chevallier, “High strength – High conductivity double-walled carbon nanotube – Copper composite wires,” Carbon N. Y. 96, 212–215 (2016).

QHF Chen, Jiamin Ying, Yifei Wang, Shiyu Du, Zhaoping Liu (2016) Effects of graphene content on the microstructure and properties of copper matrix composites. Carbon 96:836–842.

S. F. Moustafa, S. A. El-Badry, A. M. Sanad, and B. Kieback, “Friction and wear of copper–graphite composites made with Cu-coated and uncoated graphite powders,” Wear 253, 699–710 (2002).

S. F. Moustafa, S. A. El-Badry, and A. M. Sanad, “Effect of Graphite with and Without Copper Coating on Consolidation Behaviour and Sintering of Copper–Graphite Composite,” Powder Metall. 40, 201–206 (1997).

G. C. Yao, Q. S. Mei, J. Y. Li, C. L. Li, Y. Ma, F. Chen, and M. Liu, “Cu/C composites with a good combination of hardness and electrical conductivity fabricated from Cu and graphite by accumulative roll-bonding,” Mater. Des. 110, 124–129 (2016).

S. Zhao, Z. Zheng, Z. Huang, S. Dong, P. Luo, Z. Zhang, and Y. Wang, “Cu matrix composites reinforced with aligned carbon nanotubes : Mechanical, electrical and thermal properties,” Mater. Sci. Eng. A 675, 82–91 (2016).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted April 6, 2017.

Rights and permissions

About this article

Cite this article

Saboori, A., Pavese, M., Badini, C. et al. A Novel Approach to Enhance the Mechanical Strength and Electrical and Thermal Conductivity of Cu-GNP Nanocomposites. Metall Mater Trans A 49, 333–345 (2018). https://doi.org/10.1007/s11661-017-4409-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-017-4409-y