Abstract

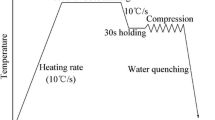

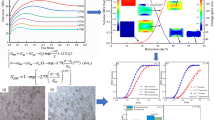

Constitutive modeling of the ingot breakdown process of large size ingots of high strength steel was carried out through comprehensive thermomechanical processing using Gleeble 3800® thermomechanical simulator, finite element modeling (FEM), optical and electron back scatter diffraction (EBSD). For this purpose, hot compression tests in the range of 1473 K to 1323 K (1200 °C to 1050 °C) and strain rates of 0.25 to 2 s−1 were carried out. The stress-strain curves describing the deformation behavior of the dendritic microstructure of the cast ingot were analyzed in terms of the Arrhenius and Hansel-Spittel models which were implemented in Forge NxT 1.0® FEM software. The results indicated that the Arrhenius model was more reliable in predicting microstructure evolution of the as-cast structure during ingot breakdown, particularly the occurrence of dynamic recrystallization (DRX) process which was a vital parameter in estimating the optimum loads for forming of large size components. The accuracy and reliability of both models were compared in terms of correlation coefficient (R) and the average absolute relative error (ARRE).

Similar content being viewed by others

References

SF2000 Data Sheet (2013), http://www.sorelforge.com. Accessed September 2013.

H.J. McQueen and J.J. Jonas, in Treatise on Materials Science & Technology, ed. A. R.J, Elsevier, 1975, vol. Volume 6, pp. 393–493.

E.I. Poliak and J.J. Jonas, ISIJ International, 2003, 43, 684-691.

E.I. Poliak and J.J. Jonas, ISIJ International, 2003, 43, 692-700.

A. Marchattiwar, A. Sarkar, J.K. Chakravartty and B.P. Kashyap, J. of Materi Eng and Perform, 2013, 22, 2168-2175.

Y. Han, G. Qiao, J. Sun and D. Zou, Computational Materials Science, 2013, 67, 93-103.

Y.C. Lin and C. Xiao-Min, Materials & Design, 2011, 32, 1733-1759.

Y.C. Lin and X.M. Chen, Computational Materials Science, 2010, 49, 628-633.

D. Samantaray, S. Mandal and A.K. Bhaduri, Computational Materials Science, 2009, 47, 568-576.

D.L. Preston, D.L. Tonks and D.C. Wallace, Journal of Applied Physics, 2003, 93, 211-220.

M.C. Price, A.T. Kearsley and M.J. Burchell, International Journal of Impact Engineering, 2013, 52, 1-10.

H.Y. Li, D.-D. Wei, Y.H. Li and X.F. Wang, Materials & Design, 2012, 35, 557-562.

O. Sabokpa, A. Zarei-Hanzaki, H.R. Abedi and N. Haghdadi, Materials & Design, 2012, 39, 390-396.

Y.F. Li, Z.H. Wang, L.Y. Zhang, C. Luo and X.C. Lai, Transactions of Nonferrous Metals Society of China, 2015, 25, 1889-1900.

H.J. McQueen and N.D. Ryan, Materials Science and Engineering: A, 2002, 322, 43-63.

M. El Mehtedi, F. Musharavati and S. Spigarelli, Materials & Design, 2014, 54, 869-873.

A. Hensel and T. Spittel, Kraft-und Arbeitsbedarf bildsamer Formgeburgsverfahren. VEB DeutscherVerlag fur Grundstoffindustrie, Leipzig, 1978 (in German).

Y.C. Lin, M.S. Chen and J. Zhong, Computational Materials Science, 2008, 42, 470-477.

Y.C. Lin, M.S. Chen and J. Zhong, Mechanics Research Communications, 2008, 35, 142-150.

Y.C. Lin and G. Liu, Computational Materials Science, 2010, 48, 54-58.

W. Peng, W. Zeng, Q. Wang and H. Yu, Materials & Design, 2013, 51, 95-104.

H. Yuan-Chun, Y.C. Lin, D. Jiao, L. Ge and C. Ming-Song, Materials & Design, 2014, 53, 349-356.

S. Marie, R. Ducloux, P. Lasne, J. Barlier and L. Fourment, ESAFORM 2014, Espoo, Finland, 2014.

P. Opla, I. Schindler, T. Petrek, P. Kawulok, F. Vanura, R. Kawulok and S. Rusz, METAL 2014, Brno, Czech republic, 2014.

X. Duan and T. Sheppard, Journal of Materials Processing Technology, 2004, 150, 100-06.

S.L. Semiatin, D.S. Weaver, R.C. Kramb, P.N. Fagin, M.G. Glavicic, R.L. Goetz, N.D. Frey and M.M. Antony, Metallurgical and Materials Transactions A, 2004, 35A, 679-693.

S.I. Oh, S.L. Semiatin and J.J. Jonas, MTA, 1992, 23, 963-975.

G.E. Dieter, H.A. Kuhn and S.L. Semiatin, Handbook of Workability and Process Design, Asm International, 2003.

G.Z. Quan, G.S. Li, T. Chen, Y.X. Wang, Y.W. Zhang and J. Zhou, Materials Science and Engineering: A, 2011, 528, 4643-4651.

M.-S. Chen, Y.C. Lin and X.-S. Ma, Materials Science and Engineering: A, 2012, 556, 260-266.

X. Xiao, G.Q. Liu, B.F. Hu, X. Zheng, L.N. Wang, S.J. Chen and A. Ullah, Computational Materials Science, 2012, 62, 227-234.

J.J. Jonas, C. Ghosh, X. Quelennec and V.V. Basabe, ISIJ International, 2013, 53, 145-151.

E.I. Poliak and J.J. Jonas, Acta Materialia, 1996, 44, 127-136.

K. Chadha, D. Shahriari and M. Jahazi, La Metallurgia Italiana - International Journal of the Italian Association for Metallurgy, 2016, 4, 5-12.

J. Rojek, O.C. Zienkiewicz, E. Oñate and E. Postek, Journal of Materials Processing Technology, 2001, 119, 41-47.

P. Mahajan, L. Fourment and J.L. Chenot, Engineering Computations, 1998, 15, 908-924.

R.L. Goetz and S.L. Semiatin, J. of Materi Eng and Perform, 2001, 10, 710-717.

M.C. Mataya and V.E. Sackschewsky, Metallurgical and Materials Transactions A, 1994, 25, 2737-2752.

K. Chadha, D. Shahriari and M. Jahazi, presented in part at the FiMPART, Hyderabad, India, 2015.

L. Yunping, E. Onodera and A. Chiba, Materials Transactions, 2010, 51, 1210-1215.

Y.C. Lin, M.S. Chen and J. Zhong, Journal of Central South University (Science and Technology), 2008, 39, 549-553.

Y.C. Lin, M.S. Chen and J. Zhong, Computational Materials Science, 2008, 44, 316-321.

S.L. Semiatin, D.S. Weaver, P.N. Fagin, M.G. Glavicic, R.L. Goetz, N.D. Frey, R. C. Kramb and M.M. Antony, Metallurgical and Materials Transactions A (Physical Metallurgy and Materials Science), 2004, 35A, 679-693.

S. Hotta, T. Murakami, T. Narushima, Y. Iguchi and C. Ouchi, ISIJ International, 2005, 45, 338-346.

D. Samantaray, S. Mandal and A.K. Bhaduri, Materials & Design, 2011, 32, 2797-2802.

Acknowledgments

The authors are very much grateful to Finkl Steel for providing the specimens for the present research. The authors would also like to thank National Science Engineering Research Council (NSERC) Canada for their support in the framework of a Collaborative Research and Development project (CRD) and Transvalor Americas Corp for permission to use Forge NxT 1.0® software. One of the authors (Kanwal Chadha) would like to acknowledge the support of ÉTS, Canada for financial support for visiting Indian Institute of Technology, Hyderabad, India for carrying out the EBSD characterization.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Manuscript submitted September 3, 2016.

Appendix

Appendix

Arrhenius-type model[31] is used to describe the relationship between flow stress, deformation temperature and strain rate during high temperature deformation. It is given by

Generally, F (σ) is in the form of power function or exponential function or hyperbolic sine function as listed below:

where, A, n 1, n, α and β are the material constants, with α = β/ n 1 .

In order to find the constants, the value of F (σ) is put into Eq. [A2] which gives the relationship of low-level stress (ασ < 0.8) and high-level stress (ασ > 1.2).

B, B, and \( n_{1} \) are material constants which are independent of deformation temperatures. These constants can be calculated by taking logarithm on both sides of Eq. [A3].

Plotting graphs of lnσ vs ln \( \dot{\varepsilon } \) and σ vs ln \( \dot{\varepsilon } , \) by the linear regression method gives the values of \( n_{1 } \)and β. The values are calculated using the average values of slope of parallel lines from different temperatures. Putting these values, value of α= β/ n 1 can be found.

In order to calculate the value of Q, logarithm on both sides of Eq. [A2] of the function is taken for all values of stress and then assuming it as independent of temperature gives,

\( ln\dot{\varepsilon } \) and 1/T are considered as two independent variables. Differentiating the above equation gives,

(T and \( \dot{\varepsilon } \) taken as independent variables).

Using these equations, plots of \( { \ln }[\sinh \left( {\alpha \sigma } \right)] - { \ln }\dot{\varepsilon } \) and \( {\text{ln}}[\sinh \left( {\alpha \sigma } \right)] - \left( {\frac{1}{T}} \right) \) can be generated and subsequently the value of n and Q can be found using regression analysis of experimental results. The value of the constant lnA can be found from the intercept of \( { \ln }[\sinh \left( {\alpha \sigma } \right)] - { \ln }\dot{\varepsilon } \) plots.

Rights and permissions

About this article

Cite this article

Chadha, K., Shahriari, D., Tremblay, R. et al. Deformation and Recrystallization Behavior of the Cast Structure in Large Size, High Strength Steel Ingots: Experimentation and Modeling. Metall Mater Trans A 48, 4297–4313 (2017). https://doi.org/10.1007/s11661-017-4177-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-017-4177-8