Abstract

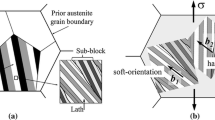

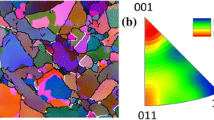

A lath martensite steel containing 0.22 mass pct carbon was analyzed in situ during tensile deformation by high-resolution time-of-flight neutron diffraction to clarify the large work-hardening behavior at the beginning of plastic deformation. The diffraction peaks in plastically deformed states exhibit asymmetries as the reflection of redistributions of the stress and dislocation densities/arrangements in two lath packets: soft packet, where the dislocation glides are favorable, and hard packet, where they are unfavorable. The dislocation density was as high as 1015 m−2 in the as-heat-treated state. During tensile straining, the load and dislocation density became different between the two lath packets. The dislocation character and arrangement varied in the hard packet but hardly changed in the soft packet. In the hard packet, dislocations that were mainly screw-type in the as-heat-treated state became primarily edge-type and rearranged towards a dipole character related to constructing cell walls. The hard packet played an important role in the work hardening in martensite, which could be understood by considering the increase in dislocation density along with the change in dislocation arrangement.

Similar content being viewed by others

References

T. Maki: Proc. 1st Int. Symp. on Steel Sci., 2007, pp. 1–10.

S. Morito, H. Tanaka, R. Konishi, T. Furuhara and T. Maki: Acta Mater., 2003, vol. 51, pp. 1789–99.

H. Kitahara, R. Ueji, N. Tsuji and Y. Minamino: Acta Mater., 2006, vol. 54, pp. 1279–88.

K. Nakashima, Y. Fujimura, H. Matsubayashi, T. Tsuchiyama and S. Takaki: Tetsu-to-Hagane, 2007, vol. 93, pp. 459–65.

S. Morooka, Y. Tomota and T. Kamiyama: ISIJ Int., 2008, vol. 48, pp. 525–30.

G.K. Williamson and R.E. Smallman: Phil. Mag., 1956, vol. 1, pp. 34–46.

G.I. Taylor: Proc. R. Soc. A, 1934, vol. 45, pp. 362–87.

T. Ungár, L. Li, G. Tichy, W. Pantleon, H. Choo and P.K. Liaw: Scripta Mater., 2011, vol. 64, pp. 876–79.

B. Hutchinson, D. Lindell and M. Barnett: ISIJ Int., 2015, vol. 55, pp. 1114–22.

M.R. Daymond, C.N. Tomé and M.A.M. Bourke: Acta Mater., 2000, vol. 48, pp. 553–64.

Y. Tomota, P. Lukas, S. Harjo, J-H. Park, N. Tsuchida and D. Neov: Acta Mater., 2003, vol. 51, pp. 819–30.

Y. Tomota, H. Tokuda, Y. Adachi, M. Wakita, N. Minakawa, A. Moriai and Y. Morii: Acta Mater., 2004, vol. 52, pp. 5737–45.

M.R. Daymond, C. Hartig and H. Mecking: Acta Mater., 2005, vol. 53, pp. 2805–13.

O. Muransky, P. Sittner, J. Zrnik and E.C. Oliver: Acta Mater., 2008, vol. 56, pp. 3367–79.

S. Harjo, J. Abe, K. Aizawa, W. Gong and T. Iwahashi: JPS Conf. Proc., 2014, vol. 1, 014017.

S. Morooka, T. Tsuchiyama, S. Harjo and K. Aizawa: CAMP-ISIJ, 2014, vol. 168, p. 866.

T. Ungár, S. Harjo, T. Kawasaki, Y. Tomota, G. Ribarik and Z. Shi: Metall. Mat. Trans. A, 2016, vol 48A, pp. 159–167.

H. Mughrabi, T. Ungár, W. Kienle and M. Wilkens: Philos. Mag. A, 1986, vol. 53, pp. 793–813.

B. Jakobsen, H.F. Poulsen, U. Lienert, J. Almer, S.D. Shastri, H.O. Sørensen, C. Gundlach and W. Pantleon: Science, 2006, vol. 312, pp. 889–92.

T. Ungár, J. Gubicza, G. Ribarik and A. Borbely: J. Appl. Cryst., 2001, vol. 34, pp. 298–310.

G. Ribarik and T. Ungár: Mater. Sci. Eng. A, 2010, vol. 528, pp. 112-21.

Z. Shi, K. Liu, M. Wang, J. Shi, H. Dong, J. Pu, B. Chi, Y. Zhang and L. Jian: Met. Mater. Int., 2012, vol. 18, pp. 317–20.

S. Harjo, T. Ito, K. Aizawa, H. Arima, J. Abe, A. Moriai, T. Iwahashi and T. Kamiyama: Mater. Sci. Forum, 2011, vol. 681, pp. 443–48.

R. Oishi, M. Yonemura, Y. Nishimaki, S. Torii, A. Hoshikawa, T. Ishigaki, T. Morishima, K. Mori and T. Kamiyama: Nucl. Instrum. Methods A, 2009, vol. 600, pp. 94–96.

K. Iakoubovskii, K. Mitsuishi and K. Furuya: Nanotechnology, 2008, vol. 19, 155705.

O.D. Sherby, J. Wadsworth, D.R. Lesuer and C.K. Syn: Mater. Trans., 2008, vol. 49, pp. 2016–27.

Y. Tomota, H. Tokuda, S. Torii and T. Kamiyama: Mater. Sci. Eng. A, 2006, vol. 434, pp. 82–87.

L.D. Landau and E.M. Lifshitz: Theory of Elasticity, 1st English ed., Pergamon Press, London, 1959, pp. 1–42.

T.H. Courtney, Mechanical Behavior of Materials, 2nd ed., Waveland Press Inc., Long Grove, 1990, pp. 44–84.

S.A. Kim and W.L. Johnson: Mater. Sci. Eng. A, 2007, vol. 452–453, pp. 633–39.

T. Ungár and A. Borbély: Appl. Phys. Lett., 1996, vol. 69, pp. 3173–75.

T. Ungár and G. Tichy: Phys. Stat. Sol. (a), 1999, vol. 171, pp. 425–34.

T. Ungár, I. Dragomir, Á. Révész and A. Borbély: J. Appl. Cryst., 1999, vol. 32, pp. 992–1002.

A. Shibata, S. Morito, T. Furuhara and T. Maki: Acta Mater., 2009, vol. 57, pp. 483–92.

S. Morito, J. Nishikawa and T. Maki: ISIJ Int., 2003, vol. 43, pp. 1475–77.

T. Ungár, A.D. Stoica, G. Tichy, X.L. Wang: Acta Mater., 2014, vol. 66, pp. 251–61.

X. Huang, S. Morito, N. Hansen and T. Maki: Metall. Mater. Trans. A, 2012, vol. 43A, pp. 3517–31.

V. Vitek: Phil. Mag., 2004, vol. 84, pp. 415–28.

U. Essmann and H. Mughrabi: Philos. Mag. A, 1979, vol. 40, pp. 731–56.

D. Akama, T. Tsuchiyama and S. Takaki: ISIJ Int., 2016, vol. 56, pp. 1675–80.

S. Morito, T. Ohba, A.K. Das, T. Hayashi and M. Yoshida: ISIJ Int., 2013, vol. 53, pp. 2226–32.

D. A. Hughes and N. Hansen: Acta Mater., 2000, vol. 48, pp. 2985–3004.

J. Stráská, M. Janeček, J. Gubicza, T. Krajňák, E.Y. Yoon, H.S. Kim, Mater. Sci. Eng. A, 2015, vol. 625, pp. 98–106.

H. Mughrabi: Mater. Sci. Eng., 1987, vol. 85, pp. 15–35.

N. Hansen and X. Huang: Acta Mater., 1998, vol. 46, pp. 1827–36.

T. Waitz, H.P. Karnthaler and R.Z. Valiev: in Zehetbauer, M.J., Valiev, R.Z. (Eds.), Nanomaterials by Severe Plastic Deformation, 2004, Wiley-VCH, New York, pp. 337–50.

J.A. El-Awady: Nat. Commun., 2015, vol. 6, 5926.

K. Hanson and J.W. Morris Jr.: J. Appl. Phys., 1975, vol. 46, pp. 983–90.

E. Schafler, K. Simon, S. Bernstorff, P. Hanák, G. Tichy, T. Ungár and M.J. Zehetbauer: Acta Mater., 2005, vol. 53, pp. 315–22.

H. Mughrabi: Curr. Opin. Solid State Mater. Sci., 2016, vol. 20, pp. 411–20.

Acknowledgments

The authors acknowledge Professor Shigeo Sato of Ibaraki University for the valuable discussion. ND experiments were performed at BL19 in the Materials and Life Science Facility of J-PARC under proposals 2014I0019 and 2014P0102. Partial financial support was provided by the Japan Society for the Promotion of Science Grant-in-Aid for Scientific Research (Grant Nos. 26289264, 15H05767) and Education Commission of Hubei Province of China (Grant No. B20161203).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted December 15, 2016.

Rights and permissions

About this article

Cite this article

Harjo, S., Kawasaki, T., Tomota, Y. et al. Work Hardening, Dislocation Structure, and Load Partitioning in Lath Martensite Determined by In Situ Neutron Diffraction Line Profile Analysis. Metall Mater Trans A 48, 4080–4092 (2017). https://doi.org/10.1007/s11661-017-4172-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-017-4172-0