Abstract

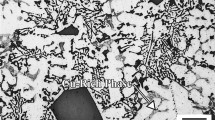

Objective of this work is to study the generation of hot tears during solidification of Al-1 wt pct Cu alloy, which contain both columnar and equiaxed structures at various strain rates. To reach this goal, an experimental test was designed for applying tensile load on the solidifying shell. The shells were loaded at various pull-rates of 0.1, 0.2, and 0.3 mm/s. The produced samples were studied using scanning electron microscope (SEM) equipped with energy dispersive X-ray spectroscopy probe and metallography techniques. SEM images revealed that both segregated hot tear (i.e., filled or healed crack) and open hot tears were formed. Hot tears had created severely segregated zones with high concentration of Cu and Fe elements formed in between dendrite arms along the primary grain boundaries. In all cases, open hot tears were formed due to cracking of the segregated zones. With increasing strain rate, lengths of segregated hot tears were increased, moving closer toward the center of the cast. At the highest strain rate, segregated hot tears were formed in the equiaxed grain region along the primary grain boundary.

Similar content being viewed by others

Abbreviations

- \( \dot{\varepsilon } \) :

-

Strain rate (s−1)

- V :

-

Separation rate (mm/s)

- H :

-

Height (mm)

- ρ :

-

Mass density (kg/m3)

- T :

-

Temperature (K)

- t :

-

Time (seconds)

- r :

-

Radial distance (m)

- K :

-

Thermal conductivity (W/m K)

- c′:

-

Equivalent heat capacity (J/kg K)

- c :

-

Specific heat (J/kg K)

- L :

-

Latent heat (J/kg)

- T l :

-

Liquidus temperature (K)

- T s :

-

Solidus temperature (K)

- f s :

-

Solid fraction

- k 0 :

-

Equilibrium partition coefficient

- T pouring :

-

Pouring temperature (K)

- h :

-

Transient transfer coefficient (J/m2 K)

- T ∞ :

-

Ambient temperature (K)

References

D.G. Eskin and L. Katgerman: Metall. Mater. Trans. A, 2007, vol. 38A, pp. 1511–19. doi:10.1007/s11661-007-9169-7.

J.G. Kaufman and E.L. Rooy: Aluminum Alloy Castings Properties, Processes, and Applications, ASM International, Materials Park, 2004.

F. D’Elia, C. Ravindran, and D. Sediako: Mater. Sci. Eng. A, 2015, vol. 624, pp. 169–80. doi:10.1016/j.msea.2014.11.057.

S. Li, K. Sadayappan, and D. Apelian: Mater. Trans. B, 2013, vol. 44, pp. 614–23. doi:10.1007/s11663-013-9801-4.

X. Zhang, J. Sun, M. Wang, Y. Zhang, N. Ma, and H. Wang: J. Rare Earth, 2015, vol. 33, pp. 1335–40. doi:10.1016/S1002-0721(14)60566-4.

A. Stangeland, A. Mo, M. M’Hamdi, D. Viano, and C. Davidson: Metall. Mater. Trans. A, 2006, vol. 37A, pp. 705–14. doi:10.1007/s11661-006-0042-x.

H. Kamguo Kamga, D. Larouche, M. Bournane, and A. Rahem: Mater. Sci. Eng. A, 2010, vol. 527, pp. 7413–23. doi:10.1016/j.msea.2010.08.025.

M.R. Nasr-Esfahani and B. Niroumand: Mater. Charact., 2010, vol. 61, pp. 318–24. doi:10.1016/j.matchar.2009.12.015.

D.G. Eskin, V.I. Savran, and L. Katgerman: Metall. Mater. Trans. A, 2005, vol. 36A, pp. 1965–76. doi:10.1007/s11661-005-0059-6.

Suyitno, D.G. Eskin, V.I. Savran and L. Katgerman: Metall. Mater. Trans. A, 2004, vol. 35A, pp. 3551–61. doi:10.1007/s11661-004-0192-7.

O. Ludwig, J.M. Drezet, C.L. Martin, and M. Suery: Metall. Mater. Trans. A, 2005, vol. 36A, pp. 1525–35. doi:10.1007/s11661-005-0244-7.

J.M. Drezet, B. Mireux, Z. Szaraz, and T. Pirling: JOM J. Miner. Met. Mater. Soc., 2014, vol. 66, pp. 1425–30. doi:10.1007/s11837-014-1018-8.

J. Campbell: Castings, 2nd ed., Butterworth-Heinemann, Oxford, 2003.

M. Merlin: Frattura Integrità Strutturale, 2010, vol. 14, pp. 64–74.

X. Yan and J.C. Lin: Metall. Mater. Trans. B, 2006, vol. 37B, pp. 913–18. doi:10.1007/BF02735013.

V.R. Voller and C.R. Swaminathan: Numer. Heat Transf. B, 1991, vol. 19, pp. 175–89. doi:10.1080/10407799108944962.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted September 3, 2016.

Rights and permissions

About this article

Cite this article

Bagheri, M., Alizadeh, M. & Ahmadi, A.R. A Study on Hot Tearing Behavior of Al-1 Wt Pct Cu Alloy Under Various Strain Rates During Casting Process. Metall Mater Trans A 48, 1856–1863 (2017). https://doi.org/10.1007/s11661-017-3993-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-017-3993-1