Abstract

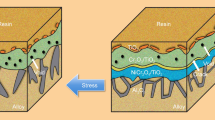

Texture evolutions and recrystallization texture features in warm- and cold-rolled sheets of high silicon electrical steel with two different initial microstructures (columnar-grained and equiaxed-grained microstructures) were investigated. The relationships between the recrystallization textures and the initial textures (the textures before rolling) of the samples were analyzed. The results showed that after annealing at 1073 K (800 °C) for 1 hour, strong {100} recrystallization textures with volume fractions of more than 47 pct were obtained in the columnar-grained samples fabricated by warm and cold rolling along the growing direction of the columnar grains. While after rolling and annealing in the same processes, only 12.8 pct volume fractions of {100} recrystallization texture were revealed in the equiaxed-grained samples. The formation of strong {100} recrystallization texture in the annealed sheets of high silicon electrical steel with initial columnar grains was attributed to the favorable texture inheritance of the initial texture during rolling and annealing. The columnar grains of strong near {100}〈001〉 ({100}〈001〉 ~ {310}〈001〉) orientation in the samples before rolling were transferred into deformed grains with orientations such as {100}〈011〉 and {100}〈012〉. after rolling. Afterwards, these deformed grains were further transferred into {100} oriented recrystallized grains, which formed strong {100} recrystallization texture in the annealed sheets and exhibited preferable soft magnetic properties.

Similar content being viewed by others

References

T. Imamura, Y. Shingaki and Y. Hayakawa: Metall Mater Trans A. 2013, vol. 44A, pp. 1785-1792.

S.W. Cheong, E.J. Hilinski and A.D. Rollett: Metall Mater Trans A. 2003, vol. 34A, pp. 1311-1319.

D. Stojakovic, R.D. Doherty, S.R. Kalidindi and F.J.G. Landgraf: Metall Mater Trans A. 2008, vol. 39, pp. 1738-1746.

M. Gallaugher, A. Samimi, T.W. Krause, L.C. Clapham and R.R. Chromik: Metall Mater Trans A. 2015, vol. 46A, pp. 1262-1276.

R. PremKumar, I. Samajdar, N.N. Viswanathan, V. Singal and V. Seshadri: J Magn Magn Mater. 2003, vol. 264, pp. 75-85.

B.D. Boer and J. Wieting: Scripta Mater. 1997, vol. 37, pp. 753-760.

F.J.G. Landgraf, T. Yonamine, R. Takanohashi, F.Q. Silva, J.P.V. Tosetti, F.B. Neto, E. Albertin, V.N.G. Mazzarella, I.G.S. Falleiros and M. Emura: J Magn Magn Mater. 2003, vol. 254, pp. 364-366.

T. Yonamine, N.A. Castro and F.J.G. Landgraf: Steel Res Int. 2005, vol. 76, pp. 461-463.

L. Cheng, N. Zhang, P. Yang and W.M. Mao: Scripta Mater. 2012, vol. 67, pp. 899-902.

H.Z. Li, H.T. Liu, Z.Y. Liu, H.H. Lu, H.Y. Song and G.D. Wang: Mater Charact. 2014, vol. 88, pp. 1-6.

J.L. Walter and E.F. Koch: Acta Metall. 1963, vol. 11, pp. 923-938.

H.D. Fu, Z.H. Zhang, Y.B. Jiang and J.X. Xie: Mater Lett. 2011, vol. 65, pp. 1416-1419.

H.D. Fu, Z.H. Zhang, Q. Yang and J.X. Xie: Mater Sci Eng A. 2011, vol. 528, pp. 1391-1395.

Z.H. Zhang, W.P. Wang, H.D. Fu and J.X. Xie: Mater Sci Eng A. 2011, vol. 530, pp. 519-524.

Y.K. Mo, Z.H. Zhang, H.D. Fu, H.J. Pan and J.X. Xie: Mater Sci Eng A. 2014, vol. 594, pp. 111-117.

J.X. Xie, H.J. Pan, H.D. Fu and Z.H. Zhang: Procedia Eng. 2014, vol. 81, pp. 149-154.

H.J. Pan, Z.H. Zhang and J.X. Xie: J Magn Magn Mater. 2016, vol. 401, pp. 625-632.

H. Haiji, K. Okada, T. Hiratani, M. Abe and M. Ninomiya: J Magn Magn Mater. 1996, vol. 160, pp. 109-114.

J.J. Sidor, K. Verbeken, E. Gomes, J. Schneider, P.R. Calvillo and L. Kestens: Mater Charact. 2012, vol. 71, pp. 49-51.

L. Kestens, J.J. Jonas, P.V. Houtte and E. Aernout: Metall Mater Trans A. 1996, vol. 27A, pp. 2347-2358.

Y.L. He, E. Hilinski and L. Jian: Metall Mater Trans A. 2015, vol. 46A, pp. 5350-5356.

J.T. Park and J.A. Szpunar: Acta Mater. 2003, vol. 51, pp. 3037-3051.

Acknowledgment

This work was supported by the National Basic Research Program of China (973 Program) under contract number 2011CB606300.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted October 4, 2015.

Rights and permissions

About this article

Cite this article

Pan, H., Zhang, Z. & Xie, J. Preparation of High Silicon Electrical Steel Sheets with Strong {100} Recrystallization Texture by the Texture Inheritance of Initial Columnar Grains. Metall Mater Trans A 47, 2277–2285 (2016). https://doi.org/10.1007/s11661-016-3371-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3371-4