Abstract

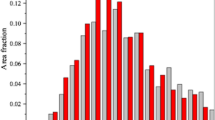

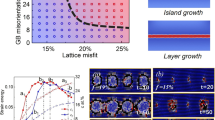

The influence of concurrent precipitation on recrystallization is analyzed by comparing the nucleation and growth behavior of P ({011} 〈566〉), Cube ({001} 〈100〉), and 20 deg ND-rotated Cube ({001} 〈310〉, NDcube)-oriented grains in Al-xMn-Fe-Si (x = 0, 0.4, 1.0 wt pct) alloys. The number densities of recrystallized grains in alloys annealed at various temperatures clearly demonstrate that concurrent precipitation significantly reduces the nucleation density of recrystallization. However, this effect varies strongly with grain orientation, and the P orientation is affected less than other orientations, in particular the Cube orientation. The number fraction of P-oriented grains can increase ten times as the effect of concurrent precipitation enhances. The P- and NDcube-oriented grains grow faster than Cube grains when strong concurrent precipitation occurs. However, on the other hand, when precipitation is limited or completely absent, P grains grow more slowly than Cube (and NDcube) grains. Micro-segregation enhances the effect of concurrent precipitation, indicating that the effect is closely related to heterogeneous distribution of precipitation.

Similar content being viewed by others

References

1. Humphreys FJ, Hatherly M : Recrystallization and Related Annealing Phenomena. Amsterdam: Elsevier; 2004.

Somerday M, Humphreys FJ: Recrystallisation behaviour of supersaturated Al–Mn alloys Part 1 – Al–13 wt%Mn. Mater Sci Technol, 2003;vol. 19, no.1, pp. 20-29.

3. Tangen S, Sjølstad K, Furu T, Nes E : Effect of Concurrent Precipitation on Recrystallization and Evolution of the P-Texture Component in a Commercial Al-Mn Alloy. Metall Mater Trans A, 2010;vol. 41, no.11, pp. 2970-2983. doi:10.1007/s11661-010-0265-8.

4. Benum S, Nes E : Effect of precipitation on the evolution of cube recrystallisation texture. Acta Mater, 1997;vol. 45, no.11, pp. 4593-4602. doi:10.1016/S1359-6454(97)00157-2.

5. Huang K, Wang N, Li Y, Marthinsen K : The influence of microchemistry on the softening behaviour of two cold-rolled Al–Mn–Fe–Si alloys. Mater Sci Eng A, 2014;vol. 601, pp. 86-96. doi:10.1016/j.msea.2014.02.037.

6. Huang K, Engler O, Li YJ, Marthinsen K : Evolution in microstructure and properties during non-isothermal annealing of a cold-rolled Al–Mn–Fe–Si alloy with different microchemistry states. Mater Sci Eng A, 2015;vol. 628, pp. 216-229. doi:10.1016/j.msea.2015.01.064.

7. Huang K, Zhao Q, Li Y, Marthinsen K : Two-stage annealing of a cold-rolled Al–Mn–Fe–Si alloy with different microchemistry states. J Mater Process Technol, 2015;vol. 221, pp. 87-99. doi:10.1016/j.jmatprotec.2015.02.016.

Humphreys FJ (1977) The nucleation of recrystallization at second phase particles in deformed aluminium. Acta Metall vol. 25, pp. 1323-1344. doi:10.1016/0001-6160(77)90109-2.

Zhang Y, Juulensen D, Zhang Y, Lin F, Zhang Z, Liu Q (2012) Three-dimensional investigation of recrystallization nucleation in a particle-containing Al alloy. Scr Mater, vol. 67, no.4, pp. 320-323. doi:10.1016/j.scriptamat.2012.05.006.

10. Vatne HE, Engler O, Nes E : Influence of particles on recrystallisation textures and microstructures of aluminium alloy 3103. Mater Sci Technol, 1997;vol. 13, no.2, pp. 93-102. doi:10.1179/mst.1997.13.2.93.

11. Engler O, Vatne HE, Nes E : The roles of oriented nucleation and oriented growth on recrystallization textures in commercial purity aluminium. Mater Sci Eng A, 1996;vol. 205, no.1-2, pp. 187-198. doi:10.1016/0921-5093(95)09879-8.

12. Schäfer C, Song J, Gottstein G : Modeling of texture evolution in the deformation zone of second-phase particles. Acta Mater, 2009;vol. 57, no.4, pp. 1026-1034. doi:10.1016/j.actamat.2008.10.052.

13. Schäfer C, Gottstein G : The origin and development of the P{011}<111> orientation during recrystallization of particle-containing alloys. Int J Mater Res, 2011;vol. 102, no.09, pp. 1106-1114. doi:10.3139/146.110567.

14. Sidor JJ, Petrov RH, Kestens LAI : Modeling the crystallographic texture changes in aluminum alloys during recrystallization. Acta Mater, 2011;vol. 59, no.14, pp. 5735-5748. doi:10.1016/j.actamat.2011.05.050.

15. Sidor JJ, Decroos K, Petrov RH, Kestens LAI : Evolution of recrystallization textures in particle containing Al alloys after various rolling reductions: Experimental study and modeling. Int J Plast, 2015;vol. 66, no.0, pp. 119-137. doi:10.1016/j.ijplas.2014.08.009.

16. Nes E, Ryum N, Hunderi O : Acta Metall, 1985;vol. 33, no.1, pp. 11-22. doi:10.1016/0001-6160(85)90214-7.

17. Liu WC, Morris JG : Recrystallization textures of the M{113} 〈110〉 and P{011} 〈455〉 orientations in a supersaturated Al–Mn alloy. Scr Mater, 2007;vol. 56, no.3, pp. 217-220. doi:10.1016/j.scriptamat.2006.10.011.

18. Liu WC, Yuan H, Huang MJ : Effect of Rolling Reduction on the P {011} <455> Recrystallization Texture in a Supersaturated Al-Mn-Mg Alloy. Metall Mater Trans A, 2009;vol. 40, no.12, pp. 2794-2797. doi:10.1007/s11661-009-9998-7.

19. Zeng Q, Wen X, Zhai T : Effect of Precipitates on the Development of P Orientation {011} <566> in a Recrystallized Continuous Cast AA 3004 Aluminum Alloy after Cold Rolling. Metall Mater Trans A, 2009;vol. 40, no.10, pp. 2488-2497. doi:10.1007/s11661-009-9942-x.

20. Huang K, Li YJ, Marthinsen K : Factors affecting the strength of P{011} 〈566〉-texture after annealing of a cold-rolled Al–Mn–Fe–Si alloy. J Mater Sci, 2015;vol. 50, no.14, pp. 5091-5103. doi:10.1007/s10853-015-9063-4.

Juul Jensen D: Growth rates and misorientation relationships between growing nuclei/grains and the surrounding deformed matrix during recrystallization. Acta Metall Mater, 1995;vol. 43, pp. 4117-4129. doi:10.1016/0956-7151(95)00111-8.

Mishin OV, Juul Jensen D, Hansen N: Evolution of Microstructure and Texture during Annealing of Aluminum AA1050 Cold Rolled to High and Ultrahigh Strains. Metall Mater Trans A, 2010;vol. 41, no.11, pp. 2936-2948. doi:10.1007/s11661-010-0291-6.

Engler O: Nucleation and growth during recrystallisation of aluminium alloys investigated by local texture analysis. Mater Sci Technol, 1996;vol. 12, pp. 859-872. doi:10.1179/mst.1996.12.10.859.

24. Daaland O, Nes E : Recrystallization texture development in commercial Al-Mn-Mg alloys. Acta Mater, 1996;vol. 44, no.4, pp. 1413-1435. doi:10.1016/1359-6454(95)00290-1.

25. Zhao Q, Holmedal B, Li Y : Influence of dispersoids on microstructure evolution and work hardening of aluminium alloys during tension and cold rolling. Philos Mag, 2013;vol. 93, no.22, pp. 2995-3011. doi:10.1080/14786435.2013.794315.

26. Li YJ, Arnberg L : Quantitative study on the precipitation behavior of dispersoids in DC-cast AA3003 alloy during heating and homogenization. Acta Mater, 2003;vol. 51, no.12, pp. 3415-3428. doi:10.1016/S1359-6454(03)00160-5.

27. Zhao Q, Holmedal B : Influence of dispersoids on grain subdivision and texture evolution in aluminium alloys during cold rolling. Trans Nonferrous Met Soc China, 2014;vol. 24, pp. 2072-2078. doi:10.1016/S1003-6326(14)63314-8.

28. Truszkowski W, Krol J, Major B : On Penetration of Shear Texture into the Rolled Aluminum and Copper. Metall Trans A, 1982;vol. 13, no.4, pp. 665-669. doi:10.1007/BF02644432.

S. Bunkholt: PhD Thesis, Norwegian University of Science and Technology, Trondheim, 2013.

N. Wang, J.E. Flatøy, Y. Li, and K. Marthinsen: ICAA13: 13th International Conference on Aluminum Alloys, Wiley, 2012, pp. 1837–42, DOI:10.1002/9781118495292.ch275.

31. Chan HM, Humphreys FJ : The recrystallisation of aluminium-silicon alloys containing a bimodal particle distribution. Acta Metall, 1984;vol. 32, no.2, pp. 235-243. doi:10.1016/0001-6160(84)90052-X.

Juuljensen D, Hansen N, Humphreys FJ: Texture development during recrystallization of aluminium containing large particles. Acta Metall, 1985; vol. 33, pp. 2155-2162. doi:10.1016/0001-6160(85)90176-2.

F.N. Rhines and R.T. DeHoff, eds.: Quantitative Microscopy, McGraw-Hill, New York, 1968.

34. Engler O, Yang P, Kong XW : On the formation of recrystallization textures in binary Al-1.3% Mn investigated by means of local texture analysis. Acta Mater, 1996;vol. 44, no.8, pp. 3349-3369. doi:10.1016/1359-6454(95)00416-5.

35. Fan GH, Zhang YB, Driver JH, Juul Jensen D : Oriented growth during recrystallization revisited in three dimensions. Scr Mater, 2014;vol. 72-73, pp. 9-12. doi:10.1016/j.scriptamat.2013.09.031.

Mishin OV, Godfrey A, Juuljensen D, Hansen N: Recovery and recrystallization in commercial purity aluminum cold rolled to an ultrahigh strain. Acta Mater, 2013;vol. 61, pp. 5354-5364. doi:10.1016/j.actamat.2013.05.024.

Acknowledgments

This work was carried out as a part of the KMB Project (193179/I40) funded by the Research Council of Norway, Hydro Aluminum and Sapa Technology. KH acknowledges the financial support from PX group EPFL.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Manuscript submitted June 13, 2015.

Rights and permissions

About this article

Cite this article

Zhao, Q., Huang, K., Li, Y. et al. Orientation Preference of Recrystallization in Supersaturated Aluminum Alloys Influenced by Concurrent Precipitation. Metall Mater Trans A 47, 1378–1388 (2016). https://doi.org/10.1007/s11661-015-3314-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-015-3314-5