Abstract

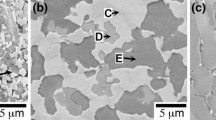

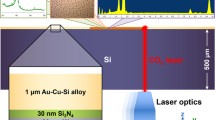

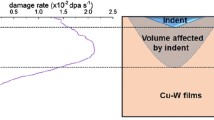

Compositionally graded Cu-Zr specimens covering a wide composition range (30 to 60 at. pct Zr) were fabricated by direct laser deposition. By observing the surface topography of the as-fabricated specimens with differential interference contrast microscopy, primarily amorphous regions corresponding to compositions of high glass-forming ability were rapidly identified. Electron diffraction results confirmed the relationship between surface topography and atomic structure. The compositional widths of the amorphous regions were observed to narrow with increasing heat input from the laser, enabling further identification of local maxima in the glass-forming landscape of Cu-Zr alloys. In this work, we report two peaks in the glass-forming ability, located at Cu64.7Zr35.3 and Cu50.2Zr49.8. These two compositions find excellent agreement with previously reported results based on casting of discrete compositions.

Similar content being viewed by others

References

W. Klement, R. Willens, and P. Duwez, Nature 187, 869–70 (1960).

J. F. Löffler, Intermetallics 11, 529–40 (2003).

A. Inoue, N. Nishiyama, and H. Kimura, Mater. Trans. JIM 38, 179–83 (1997).

D. Turnbull, Contemp. Phys. 10, 473–88 (1969).

A. Inoue, T. Zhang, and T. Masumoto, J. Non. Cryst. Solids 156, 473–80 (1993).

Z. Lu and C. Liu, Phys. Rev. Lett. 91, 1155051-54 (2003).

Z. L. Long, G. Q. Xie, H. Q. Wei, X. P. Su, J. Peng, P. Zhang, and A. Inoue, Mater. Sci. Eng. A 509, 23–30 (2009).

T. A. Waniuk, J. Schroers, and W. L. Johnson, Appl. Phys. Lett. 78, 1213–15 (2001).

Y. Li, J. Mater. Sci. Technol. 15, 97–110 (1999).

D. B. Miracle, Acta Mater. 54, 4317–36 (2006).

D. B. Miracle, Nat. Mater. 3, 697–702 (2004).

D.B. Miracle, A.L. Greer, and K.F. Kelton: J. Non-Cryst. Solids 354, 4049–55, 2008.

A. P. Wang, J. Q. Wang, and E. Ma, Appl. Phys. Lett. 90, 1219121–23 (2007).

J. H. Na, M. D. Demetriou, M. Floyd, A. Hoff, G. R. Garrett, and W. L. Johnson, Proc. Natl. Acad. Sci. U. S. A. 111, 9031–36 (2014).

Y. P. Deng, Y. F. Guan, J. D. Fowkes, S. Q. Wen, F. X. Liu, G. M. Pharr, P. K. Liaw, C. T. Liu, and P. D. Rack, Intermetallics 15, 1208–16 (2007).

A. Y. Li, Q. Guo, J. A. Kalb, C. V Thompson, and Y. Li, Science 322, 1816–19 (2008).

S. Y. Ding, J. Gregoire, J. J. Vlassak, and J. Schroers, J. Appl. Phys. 111, 1149011–16 (2012).

S. Y. Ding, Y. H. Liu, Y. L. Li, Z. Liu, S. Sohn, F. J. Walker, and J. Schroers, Nat. Mater. 13, 494–500 (2014).

P. Tsai and K. M. Flores, Intermetallics 55, 162–66 (2014).

J. Kim, D. Lee, S. Shin, and C. Lee, Mater. Sci. Eng. A 434, 194–201 (2006).

B. Li, Z. Y. Li, J. G. Xiong, L. Xing, D. Wang, and Y. Li, J. Alloys Compd. 413, 118–21 (2006).

D. Carvalho, S. Cardoso, and R. Vilar, Scripta Mater. 37, 523–27 (2003).

F. Audebert, R. Colaco, R. Vilar, and H. Sirkin, Scripta Mater. 48, 281–86 (2003).

X. L. Wu and Y. S. Hong, Surf. Coatings Technol. 132, 194–97 (2000).

X. Wu, B. Xu, and Y. Hong, Mater. Lett. 56, 838–41 (2002).

B. Q. Chen, Y. Li, Y. Cai, R. Li, S. J. Pang, and T. Zhang, J. Alloys Compd. 511, 215–20 (2012).

B. Zheng, Y. Zhou, J. E. Smugeresky, and E. J. Lavernia, Metall. Mater. Trans. A 40, 1235–45 (2009).

G. L. Yang, X. Lin, F. C. Liu, Q. Hu, L. Ma, J. F. Li, and W. D. Huang, Intermetallics 22, 110–15 (2012).

R. Petters, M. Stoica, S. Scudino, S. Pauly, and L. Lo, Mater. Today 16, 37–41 (2013).

D. Ausserré and M. P. Valignat, Nano Lett. 6, 1384–88 (2006).

H. Sun and K. M. Flores, J. Mater. Res. 23, 2692–703 (2011).

H. Sun and K. M. Flores, Metall. Mater. Trans. A 41, 1752–57 (2010).

D. Wang, Y. Li, B. B. Sun, M. L. Sui, K. Lu, and E. Ma, Appl. Phys. Lett. 84, 4029–31 (2004).

D. Xu, B. Lohwongwatana, G. Duan, W. L. Johnson, and C. Garland, Acta Mater. 52, 2621–24 (2004).

D. C. Hofmann, G. Duan, and W. L. Johnson, Scripta Mater. 54, 1117–22 (2005).

G. Duan, D. H. Xu, Q. Zhang, G. Y. Zhang, T. Cagin, W. L. Johnson, and W. A. Goddard, Phys. Rev. B 71, 2242081–89 (2005).

O. J. Kwon, Y. C. Kim, K. B. Kim, Y. K. Lee, and E. Fleury, Met. Mater. Int. 12, 207–12 (2006).

X. H. Lin, W. L. Johnson, and W. K. Rhim, Mater. Trans. JIM 38, 473–77 (1997).

Acknowledgments

This work was funded by the Defense Threat Reduction Agency, award number HDTRA1-11-1-0047, and the Air Force Office of Scientific Research, award number FA9550-12-1-0059. Copper powder was provided by the Materials Preparation Center, Ames Laboratory, US DOE Basic Energy Sciences, Ames, IA, USA.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted December 31, 2014.

Rights and permissions

About this article

Cite this article

Tsai, P., Flores, K.M. A Laser Deposition Strategy for the Efficient Identification of Glass-Forming Alloys. Metall Mater Trans A 46, 3876–3882 (2015). https://doi.org/10.1007/s11661-015-2900-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-015-2900-x