Abstract

Strain-controlled low-cycle fatigue (LCF) tests were conducted on ductile cast iron (DCI) at strain rates of 0.02, 0.002, and 0.0002/s in the temperature range from room temperature to 1073 K (800 °C). A constitutive-damage model was developed within the integrated creep-fatigue theory (ICFT) framework on the premise of strain decomposition into rate-independent plasticity and time-dependent creep. Four major damage mechanisms: (i) plasticity-induced fatigue, (ii) intergranular embrittlement (IE), (iii) creep, and (iv) oxidation were considered in a nonlinear creep-fatigue interaction model which represents the overall damage accumulation process consisting of oxidation-assisted fatigue crack nucleation and propagation in coalescence with internally distributed damage (e.g., IE and creep), leading to final fracture. The model was found to agree with the experimental observations of the complex DCI-LCF phenomena, for which the linear damage summation rule would fail.

Similar content being viewed by others

References

J.R. Davis, ed.: ASM Specialty Handbook: Cast Irons, ASM International, Materials Park, OH, 1996.

G.M. Goodrich, Technical Editor: Iron Castings Engineering Handbook, American Foundry Society (AFS), Des Plaines, IL, 2003.

R. Elliott, Cast Iron Technology, Butterworths, London, UK, 1988.

D. Li, R. Perrin, G. Burger, D. McFarlan, B. Black, R. Logan, and R. Williams: in Advances in Lightweight Automotive Castings and Wrought Aluminum Alloys, 2004 SAE World Congress, Detroit, MI, March 8–11, 2004, No. 2004-01-0792.

B. Black, G. Burger, R. Logan, R. Perrin, and R. Gundlach: Microstructure and Dimensional Stability in Si-Mo Ductile Irons for Elevated Temperature Applications, SAE International, No. 2002-01-2115.

D.L. Sponseller, W.G. Scholz, and D.F. Rundle, “Development of Low-Alloy Ductile Irons for Service at 1200-1500 F” AFS Trans. 1968, vol. 76, pp. 353-368.

T. Kobayashi, K. Nishino, Y. Kimoto, Y. Awano, Y. Hibino, and H. Ueno, “673K Embrittlement of Ferritic Spheroidal Graphite Cast Iron by Magnesium”, Casting Engineering, 1998, vol. 70, pp. 273-278.

D. Li and C. Sloss: Ferrous High-Temperature Alloys for Exhaust Component Applications, 2010 SAE World Congress, Detroit, MI, SAE International, No. 2010-01-0654, April 13–15, 2010.

Y.-J. Kim, H. Jang, and Y.-J. Oh, Metall. and Mater. Trans. A, 2009, vol. 40A, pp. 2087-2097.

F. Szmytka, L. Rémy, H. Maitournam, A. Köster, Int. J. Plasticity, 2010, vol. 26, pp. 905-924.

L.Rémy, F.Szmytka, L.Bucher, Int. J. Fatigue, 2013, vol. 53, pp. 2-14.

T. Seifert, H. Riedel, Int. J. Fatigue, 2010, vol. 32, pp. 1358-1367.

T. Seifert, G. Maier, A. Uihlein, K.-H. Lang, H. Riedel, Int. J. Fatigue, 2010, vol. 32, pp. 1368-1377.

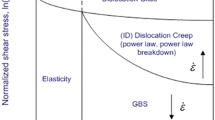

Frost, H.J. and Ashby, M.F., Deformation Mechanisms Maps, Pergamon Press, Oxford. 1982.

X.J. Wu and A.K. Koul: in Creep and Stress Relaxation in Miniature Structures and Components, H. Merchant ed., TMS, Warrendale, PA, 1996, pp. 3–19.

X.J. Wu, S. Williams, and D.G. Gong: J. Mater. Eng. Perform., 2012, DOI:10.1007/s11665-012-0191-6.

D. Slavik, and H. Sehitoglu, “Thermal stress, materials deformation, and thermo-mechanical Fatigue”, ASME, PVP 123, 1987, pp. 65-82.

J. Lemaitre, and J.L. Chaboche, Mécanique des Matériaux Solides, Dunod, Bordas, Paris, 1999.

X.J. Wu: in Gas Turbine, I. Gurrappa, ed., Sciyo, Rijeka, 2010, pp. 215–82.

X.J. Wu: Trans. ASME J. Eng. Gas Turbines Power, 2009, vol. 131, pp. 032101/1–1/6.

Wescast Industries Inc.: Internal Communication, 2011.

L.F. Coffin, Transactions of the ASME, 1954, vol. 76, pp. 931-950.

S.S. Manson, “Behaviour of Materials under Conditions of Thermal Stresses, National Advisory Co mmision on Aeronautics Report 1170, Lewis Flight Propulsion Laboratory, Cleveland, OH, 1954.

R. Neu and H. Sehitoglu: Metall. Trans. A, 1989, vol. 20A, pp. 1769–83.

M. Reger and L. Remy, Mater. Sci. Eng. A., 1988, vol. 101, pp. 47-54.

S.S. Manson, Expl. Mech. 1965, vol. 5, p. 193.

T.J. Marrow, J.-Y. Buffiere, P.J. Withers, G. Johnson, D. Engelberg, Int. J. Fatigue 2004, vol. 26, pp. 717–725.

K. Tanaka, and T. Mura, J. Appl. Mech. 1981, vol. 48, pp. 97-103.

X.J. Wu, A.K. Koul, and K.S. Krausz, Metall. Trans. A, 1993, vol. 24A, pp. 1373-1380.

G.R. Irwin: Fracture Dynamics, ASM, Cleveland, OH, 1948, pp. 147-66.

J.R. Rice: J. Appl. Mech., 1968, vol. 35, pp. 379–86.

Acknowledgments

The work was carried as collaboration between the National Research Council Canada (NRC) and Wescast Industries Inc. with partial financial support from the company. The TEM analysis was performed by Drs. Xiang Wang and Hatem Zurob at McMaster University. Luc Lafleur and Weijie Chen of NRC assisted in test equipment calibration and SEM fractorgraphy, respectively. Dr. Xiaoyang Liu of Wescast helped to construct Figure 26.

Author information

Authors and Affiliations

Corresponding author

Additional information

The following pertains only to authors Wu, MacNeil, and Zhang: Published with permission of National Research Council of Canada (the Crown in Right of Canada).

Manuscript submitted January 9, 2014.

Rights and permissions

About this article

Cite this article

Wu, X., Quan, G., MacNeil, R. et al. Failure Mechanisms and Damage Model of Ductile Cast Iron Under Low-Cycle Fatigue Conditions. Metall Mater Trans A 45, 5085–5097 (2014). https://doi.org/10.1007/s11661-014-2468-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-014-2468-x