Abstract

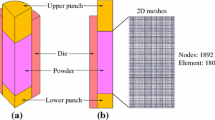

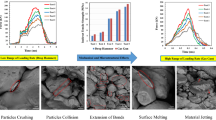

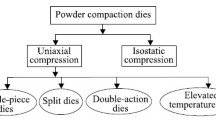

Physical experiments were carried out to study the cold compaction of copper powders under uniaxial compression using our self-designed equipment. Two kinds of copper powders with different particle sizes and distributions were considered. One-dimensional vibrations were utilized before compaction to systematically study the effect of parameters such as vibration frequency ω, amplitude A, and vibration intensity Г on the initial packing density. The macro-property and corresponding microstructures of compacts obtained from initial packings with and without vibrations were compared and analyzed. The results show that higher packing density can be obtained in the compaction of coarse powders with broad size distribution when other experimental conditions are fixed. For each powder, the evolution of packing density vs pressure takes on exponential correlation with high R 2 value. Much denser and more uniform compacts can be realized with the aid of vibration which can improve the particle rearrangement and result in the filling of macro pores formed in initial packing, and the characterization on the microstructure identifies that the particles inside the compact become polyhedrons with regular shape and uniformly distributed.

Similar content being viewed by others

References

K.A. Kuhn and C.L. Downey: Inter. J. Powder Met., 1971, vol. 7, pp. 15-25.

R.J. Green: Int. J. Mech. Sci., 1972, vol. 14, pp. 215-224.

S. Shima and M. Oyane: Int. J. Mech. Sci., 1976, vol. 18, pp. 285-291.

H.S. Kim and D.N. Lee: Powder Metall., 1992, vol. 35, pp. 275-279.

D.T. Gethin, V.D. Tran, R.W. Lewis, and A.K. Ariffin: Inter. J. Powder Met., 1994, vol.30, pp. 385-398.

Y.S. Kwon, H.T. Lee, and K.T. Kim: J. Eng. Tech., 1997, vol. 119, pp. 366-373.

W. Bier, M.P. Dariel, N. Frage, S. Hartmann, and O. Michailov: Inter. J. Mech. Sci., 2007, vol. 49, pp. 766-777.

E. Hryha, E. Dudrova and S. Bengtsson: Powder Met., 2008, vol. 51, pp. 340-342.

F.F. Lange: J. Am. Ceram. Soc., 1989, vol. 72, pp. 3-15.

R. Riedel and I.W. Chen (eds.): Ceramics Science and Technology, Synthesis and Processing, 1st ed., Wiley-VCH, GmbH & Co. KGaA, Weinheim, 2012, vol. 3, pp. 1-34.

R.M. German: Powder Metallurgy Science, Metal Powder Industries Federation, 2nd ed., Princeton, NY, 1994, pp. 192–220.

C.Y. Wu and A.C.F. Cocks: Powder Metall., 2004, vol. 47, pp. 127-136.

O. Coube, A.C.F. Cocks, and C.Y. Wu: Powder Metall., 2005, vol. 48, pp. 68-76.

X. Xie and V.M. Puri: Particulate Sci. Technol., 2006, vol. 24, pp. 411-426.

S.F. Burch, A.C.F. Cocks, J.M. Prado, and J.H. Tweed: in Modeling of Powder Die Compaction, P.R. Brewin, O. Coube, P. Doremus, and J.H. Tweed, eds., Springer, London, 2008, pp. 131–50.

C. Zhao, M.K. Jain, M. Bruhis, and R. Lawcock: Powder Technol., 2011, vol. 208, pp. 225-230.

X.Z. An, R.Y. Yang, K.J. Dong, R.P. Zou, and A.B. Yu: Phys. Rev. Lett., 2005, vol.95, pp. 205502-1-4.

X.Z. An: Chin. Phys. Lett., 2007, vol. 24, pp. 2327-2330.

X.Z. An, R.Y. Yang, R.P. Zou, and A.B. Yu: Powder Technol., 2008, vol. 188, pp. 102-109.

X.Z. An, C.X. Li, R.Y. Yang, R.P. Zou, and A.B. Yu: Powder Technol., 2009, vol. 196, pp. 50-55.

J.D. Bernal: Nature, 1959, vol. 183, pp. 141-147.

X.Z. An, B.M. Feng, C. Li, F. Huang, Z.T. Xing, C.X. Li, and L. Dong: China Invention Patent, 201110247913.X, 2011. (In Chinese)

J.B. Knight, C.G. Fandrich, C.N. Lau, H.M. Jaeger, and S.R. Nagel: Phys. Rev. E, 1995, vol. 51, pp. 3957-3963.

P. Philippe and D. Bideau: Phys. Rev. E, 2011, vol. 63, pp. 051304-1-9.

P. Philippe and D. Bideau: Europhys. Lett., 2002, vol. 60, pp. 677-683.

R.Y. Yang, R.P. Zou, and A.B. Yu: Phys. Rev. E, 2000, vol. 62, pp. 3900-3908.

G.D. Scott and D.M. Kilgour: J. Phys. D, 1969, vol. 2, pp. 863–66.

J.L. Finney: Proc. R. Soc. Lond. A, 1970, vol. 319, pp. 479-493.

R.M. German: Particle Packing Characteristics, Metal Powder Industries Federation, Princeton, New Jersey, 1989, pp. 183-192.

X.Z. An, Y.L. Zhang, Y.X. Zhang, and S. Yang: Unpublished research.

L. Parilak and E. Dudrova: Proc. PM World Cong., Paris, France, 1994, EPMA, vol. 1, pp. 737–40.

Acknowledgments

We are grateful to the financial support of National Natural Science Foundation of China (No. 50974040) and China New Century Excellent Talent Funds (NCET-10-0300).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted September 15, 2013.

Rights and permissions

About this article

Cite this article

An, X., Xing, Z. & Jia, C. Cold Compaction of Copper Powders Under Mechanical Vibration and Uniaxial Compression. Metall Mater Trans A 45, 2171–2179 (2014). https://doi.org/10.1007/s11661-013-2160-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-013-2160-6