Abstract

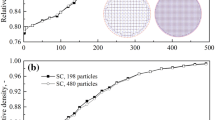

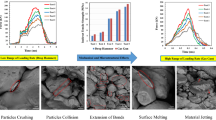

Single-action die compaction of copper powders with initial loose natural packing and vibrated random dense packing structures was carried out numerically by finite element method and physically for validation. Furthermore, the compaction under various cyclic loadings was modeled to identify its effects on the compact properties. The results were analyzed and compared between compacts formed at different initial packing structures and different forming conditions, which indicate that at the same pressure, single-action die compaction on the dense uniform initial packing can produce compacts with high relative density, uniform density and stress distributions, which implies the necessity to improve initial packing density and uniformity in forming high performance compacts. Meanwhile, by using cyclic loading on such dense initial packing structures, compacts with higher packing density and more uniform density and stress distributions can be created. The numerical and physical results are comparable and in good agreement with the proposed double logarithmic equation.

Similar content being viewed by others

References

R.W. Lewis, A.G.K. Jinka, and D.T. Gethin: Int. J. Powder Metall., 1993, vol. 25, pp. 287-293.

D.T. Gethin, V.D. Tran, R.W. Lewis, and A.K. Ariffin: Int. J. Powder Metall., 1994, vol. 30, pp. 385-398.

I.C. Sinka: Kona, 2007, vol. 25, pp. 4-22.

N.A. Fleck: J. Mech. Phys. Solids, 1995, vol. 43, pp. 1409-1431.

H.S. Kim, Y. Estrin, E.Y. Gutmanas, and C.K. Rhee: Mat. Sci. Eng. A, 2001, vol. 307, pp. 67-73.

C.L. Martin, D. Bouvard, and S. Shima: J. Mech. Phys. Solids, 2003, vol. 51, pp. 667-693.

H.P. Yu and C.F. Li: Acta Metallurgica Sinnica (English letters), 2007, vol. 20, pp. 277-283.

H.A. Al-Qureshi, M.R.F. Soares, D. Hotza, M.C. Alves, and A.N. Klein: J. Mat. Proc. Technol., 2008, vol. 199, pp. 417-424.

O. Coube and H. Riedel: Powder Metall., 2000, vol. 43, pp. 123-131.

W. Bier, M.P. Dariel, N. Frage, S. Hartmann, and O. Michailov: Int. J. Mech. Sci., 2007, vol. 49, pp. 766-777.

P.R. Brewin, O. Coube, P. Doremus, and J.H. Tweed, eds.: Modelling of Powder Die Compaction, Engineering Materials and Processes, Springer, New York, 2008, pp. 1–29.

S.G. Selig and D.A. Doman: Journal of Machinery Manufacturing and Automation, 2014, vol. 3, pp. 32-40.

Y.X. Zhang, X.Z. An, and Y.L. Zhang: Applied Physics A, 2015, vol. 118, pp. 1015-1021.

R.M. German: Powder Metallurgy Science, 2nd ed., Metal Powder Industries Federation, Princeton, NY, 1994, pp. 192-220.

C.Y. Wu and A.C.F. Cocks: Powder Metall., 2004, vol. 47, pp. 127-136.

O. Coube, A.C.F. Cocks, and C.Y. Wu: Powder Metall., 2005, vol. 48, pp. 68-76.

L.C.R. Schneider, A.C.F. Cocks, and A. Apostolopoulos: Powder Metall., 2005, vol. 48, pp. 117-126.

X. Xie and V.M. Puri: Part. Sci. Technol., 2006, vol. 24, pp. 411-426.

S.F. Burch, A.C.F. Cocks, J.M. Prado, and J.H. Tweed: in Modeling of Powder Die Compaction, P.R. Brewin, O. Coube, P. Doremus, and J.H. Tweed, eds., Springer, London, 2008, pp. 131–50.

C. Zhao, M.K. Jain, M. Bruhis, and R. Lawcock: Powder Technol., 2011, vol. 208, pp. 225-230.

X.Z. An, R.Y. Yang, K.J. Dong, R.P. Zou, and A.B. Yu: Phys. Rev. Lett., 2005, vol. 95, pp. 205502-1-4.

X.Z. An, R.Y. Yang, R.P. Zou, and A.B. Yu: Powder Technol., 2008, vol. 188, pp. 102-109.

X.Z. An, C.X. Li, R.Y. Yang, R.P. Zou, and A.B. Yu: Powder Technol., 2009, vol. 196, pp. 50-55.

X.Z. An. Z.T. Xing, and C.C. Jia: Metall. Mater. Trans. A, 2014, vol. 45, pp. 2171-2179.

Y.L. Wu, X.Z. An, and F. Huang: Mater. Res. Innov., 2014, vol. 18, pp. 1082-1086.

X.Z. An, S.S. He, H.D. Feng, and Q. Qian: Applied Physics A, 2015, vol. 118, pp. 151-162.

M. Oyane, S. Shima, and Y. Kono: Bull. JSME, 1977, vol. 16, pp. 1254-1262.

Y. Corapcioglu and T. Uz: Powder Technol., 1978, vol. 21, pp. 269-274.

S. Shima and M. Oyane: Int. J. Mech. Sci., 1976, vol. 18, pp. 285-291.

A.L. Gurson: J. Eng. Mater-T. Asme., 1977, vol. 99, pp. 2-5.

X.P. Ren: Powder Metallurgy Technology, 1992, vol. 10, pp. 9-12. (In Chinese).

N.A. Fleck, L.T. Kuhn, and R.M. McMeeking: J. Mech. Phys. Solids, 1992, vol. 40, pp. 1139-1162.

AR.Khoei,M.Mofid,and A.Bakhshiani: J. Mat. Proc. Technol., 2002, vol. 130-131, pp. 75-180.

S. Kobayashi, S.I. Oh, and T. Altan: Metal Forming and the Finite Element method, Oxford University Press, Oxford, 1989.

A.H. Tavakoli, A. Simchi, and S.M. Seyed Reihani: Compos. Sci. Technol., 2005, vol. 65, pp. 2094-2104.

Acknowledgments

We are grateful to the financial support of National Natural Science Foundation of China (50974040), China New Century Excellent Talent Funds (NCET-10-0300), and Fundamental research funds for the Central Universities of China (N120202001).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted April 24, 2014.

Rights and permissions

About this article

Cite this article

An, X., Zhang, Y., Zhang, Y. et al. Finite Element Modeling on the Compaction of Copper Powder Under Different Conditions. Metall Mater Trans A 46, 3744–3752 (2015). https://doi.org/10.1007/s11661-015-2929-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-015-2929-x