Abstract

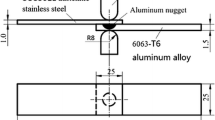

The structural applications of lightweight aluminum alloys inevitably involve dissimilar welding with steels and the related durability issues. This study was aimed at evaluating the microstructural change, lap shear tensile load, and fatigue resistance of dissimilar ultrasonic spot-welded joints of aluminum-to-galvanized high-strength low-alloy (HSLA) steel. Two non-uniform layers were identified in between Al and HSLA steel via SEM/EDS and XRD. One was an Al-Zn eutectic layer and the other was a thin (<2 μm) layer of intermetallic compound (IMC) of Al and Fe in the nugget zone. The lap shear tensile testing gave a maximum load of 3.7 kN and the sample failed initially in between the Al-Zn eutectic film and Al-Fe IMC, and afterward from the region containing Al on both matching fracture surfaces. The fatigue test results showed a fatigue limit of about 0.5 kN (at 1 × 107 cycles). The maximum cyclic stress at which transition of the fatigue fracture from transverse through-thickness crack growth mode to the interfacial failure mode occurs increases with increasing energy input.

Similar content being viewed by others

References

Y.C. Chen, T. Komazaki, Y.G. Kim, T. Tsumura, and K. Nakata: Mater. Chem. Phys. 2008, vol. 111, pp. 375–80.

E.J. Lavernia, R.J. Perez, and J. Zhang: Metall. Trans. A, 1985, vol. 26A, pp. 2803–18.

L. Xiao, L. Liu, Y Zhou, and S Esmaeili: Metall. Mater. Trans. A, 2010, vol. 41-6, pp. 1511–22.

P.B. Prangnell, F. Haddadi, and Y.C. Chen: Mater. Sci. Technol., 2011, vol. 27, pp. 617−24.

R. Jahn, R. Cooper, and D. Wilkosz: Metall. Mater. Trans. A, 38 (2007) 570−83.

E. Hetrick, R. Jahn, L. Reatherford, J. Skogsmo, S. Ward, D. Wilkosz, J. Devine, K. Graff, and R. Gehrin: Weld. J., 2005, vol. 84, pp. 26−30.

P.B. Prangnell and D. Bakavos: Mater. Sci. Forum, 2010, vol. 638-642, pp. 1237−42.

V.K. Patel, S.D. Bhole, and D.L. Chen: Scr. Mater., 2011, vol. 65, pp. 911–14.

S.H. Chowdhury, D.L. Chen, S.D. Bhole, X. Cao, and P. Wanjara: Mater. Sci. Eng., A, 2012, vol. 556, pp. 500–09.

S. Elangovan, S Semeer, and K. Prakasan: J. Mater. Process. Technol., 2009, vol. 209, pp. 1143–50.

S. Chen, J. Huang, K. Ma, H. Zhang, and X. Zhao: Mater. Lett. 2012, vol. 79, pp. 296-99.

C.Y. Lee, D.H. Choi, Y.M. Yeon, and S.B. Jung: Sci. Technol. Weld. Joining, 2009, vol. 14-3, pp. 216−20.

T. Watanabe, H. Sakuyama, and A. Yanagisawa: J. Mater. Process. Technol., 2009, vol. 209, pp. 5475–80.

M. Watanabe, K. Feng, Y. Nakamura, and S. Kumai: Mater. Trans., 2011, vol. 52-5, pp. 953−9.

Y.C. Chen and K. Nakata: Metall. Mater. Trans. A, 2008, vol. 39A, pp. 1985–92.

C. Maldonado, A. Medina-Flores, L. Bejar-Gomez, and A. Ruiz: Revista Mexicana De F′isica S, 2009, vol. 55-1, pp. 130–34.

F. Haddadi, D. Strong, P. B. Prangnell: JOM, 2012, vol. 64-3, pp. 407−13.

K. Ueda, T. Ogura, S. Nishiuchi, K. Miyamoto, T. Nanbu, A. Hirose: Mater. Trans., 2011, vol. 52-5, pp. 967−73.

S. Winkler, A. Thompson, C. Salisbury, M. Worswick, I. V. Riemsdijk, R. Mayer: Metall. Mater. Trans. A, 2008, vol. 39A, pp. 1350−1358.

M.S. Khan, S.D. Bhole, D.L. Chen, E. Biro, G. Boudreau, J.V. Deventer: Sci. Technol. Weld. Joining, 2009, vol. 14-7, pp. 616−25.

T.B. Massalski: ASM Binary Alloy Phase Diagrams, 2 nd ed. ASM International, Materials Park, OH, 2001, pp. 147−9.

K. Miyagawa, M. Tsubaki, T. Yasui, M. Fukumoto: Weld. Inter., 2009, vol. 23-9, pp. 648–653.

T. Franklin, J. Pan: SAE Int. J. Mater. Manuf., 2011, vol. 4-1, pp. 581–8.

Acknowledgments

The authors would like to thank the Natural Sciences and Engineering Research Council of Canada (NSERC) and AUTO21 Network of Centers of Excellence for providing financial support. This investigation involves part of Canada–China–USA Collaborative Research Project on the Magnesium Front End Research and Development (MFERD). The authors thank Dr. A.A. Luo, General Motors Research and Development Center, for the supply of test materials. One of the authors (D.L. Chen) is grateful for the financial support by the Premier’s Research Excellence Award (PREA), NSERC-Discovery Accelerator Supplement (DAS) Award, Canada Foundation for Innovation (CFI), and Ryerson Research Chair (RRC) program. The assistance of Q. Li, A. Machin, J. Amankrah, and R. Churaman in performing the experiments is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted May 27, 2013.

Rights and permissions

About this article

Cite this article

Patel, V.K., Bhole, S.D. & Chen, D.L. Ultrasonic Spot Welding of Aluminum to High-Strength Low-Alloy Steel: Microstructure, Tensile and Fatigue Properties. Metall Mater Trans A 45, 2055–2066 (2014). https://doi.org/10.1007/s11661-013-2123-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-013-2123-y