Abstract

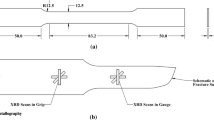

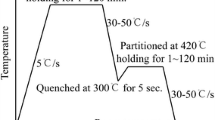

Fracture toughness K IC was measured by double edge-notched tension (DENT) specimens with fatigue precracks on quenching and partitioning (Q&P)-treated high-strength (ultimate tensile strength [UTS] superior to 1200 MPa) sheet steels consisting of 4 to 10 vol pct of retained austenite. Crack extension force, G IC, evaluated from the measured K IC, is used to analyze the role of retained austenite in different fracture behavior. Meanwhile, G IC is deduced by a constructed model based on energy absorption by martensite transformation (MT) behavior of retained austenite in Q&P-treated steels. The tendency of the change of two results is in good agreement. The Q&P-treated steel, quenched at 573 K (300 °C), then partitioned at 573 K (300 °C), holding for 60 seconds, has a fracture toughness of 74.1 MPa·m1/2, which is 32 pct higher than quenching and tempering steel (55.9 MPa·m1/2), and 16 pct higher than quenching and austempering (QAT) steel (63.8 MPa·m1/2). MT is found to occur preferentially at the tips of extension cracks on less stable retained austenite, which further improves the toughness of Q&P steels; on the contrary, the MT that occurs at more stable retained austenite has a detrimental effect on toughness.

Similar content being viewed by others

References

O. Grässel and G. Frommeyer: Mater. Sci. Technol., 1998, vol. 14, pp. 1213–17.

F.G. Caballero, M.J. Santofimia, C. García-Mateo, J. Chao, and C. García de Andrés: Mater. Des., 2009, vol. 30, pp. 2077–83.

F.G. Caballero and H.K.D.H. Bhadeshia: Curr. Opin. Solid State Mater. Sci., 2004, vol. 8, pp. 251–57.

J. Speer, D.K. Matlock, B.C. De Cooman, and J.G. Schroth: Acta Mater., 2003, vol. 51, pp. 2611–22.

D.V. Edmonds, K. He, F.C. Rizzo, B.C. De Cooman, D.K. Matlock, and J.G. Speer: Mater. Sci. Eng. A, 2006, vol. 438, pp. 25–34.

X.D. Wang, N. Zhong, Y.H. Rong, T.Y. Hsu, and L. Wang: J. Mater. Res., 2009, vol. 24, p. 261.

J.G. Speer, E. De Moor, K.O. Findley, D.K. Matlock, B.C. De Cooman, and D.V. Edmonds: Metall. Mater. Trans. A, 2011, vol. 42A, pp. 1–11.

E. De Moor, J.G. Speer, D.K. Matlock, J.H. Kwak, and S.B. Lee: Steel Res. Int., 2012, vol. 83, pp. 322–27.

H.Y. Li, X.W. Lu, W.J. Li, and X.J. Jin: Metall. Mater. Trans. A, 2010, vol. 41A, pp. 1284–300.

N. Zhong, X.D. Wang, L. Wang, and Y.H. Rong: Mater. Sci. Eng. A, 2009, vol. 506, pp. 111–16.

Y. Wang, S. Zhou, Z.H. Guo, and Y.H. Rong: Trans. Tech. Publications, 2010, pp 37–40.

ISO2566/1-1984(E): Steel—Conversion of Elongation Values, Part 1: Carbon and Alloy Steels, 1984.

ASTM E8: M Standard Test Methods for Tension Testing of Metallic Materials (Metric), Annual Book of ASTM Standards, American Society for Testing and Materials, Philadelphia, 1996.

E. De Moor, S. Lacroix, A.J. Clarke, J. Penning, and J.G. Speer: Metall. Mater. Trans. A, 2008, vol. 39A, pp. 2586–95.

E. Paravicini Bagliani, M.J. Santofimia, L. Zhao, J. Sietsma, and E. Anelli: Mater. Sci. Eng. A, 2013, vol. 559, pp. 486–95.

E.D. Moor, J.G. Speer, D.K. Matlock, J.H. Kwak, and S.B. Lee: ISIJ Int., 2011, vol. 51, pp. 137–44.

S. Zhou, K. Zhang, Y. Wang, J.F. Gu, and Y.H. Rong: Mater. Sci. Eng. A, 2011, vol. 528, pp. 8006–12.

K. Zhang, M. Zhang, Z. Guo, N. Chen, and Y. Rong: Mater. Sci. Eng. A, 2011, vol. 528, pp. 8486–91.

H. Liu, X. Lu, X. Jin, H. Dong, and J. Shi: Scripta Mater., 2011, vol. 64, pp. 749–52.

T. Tsuchiyama, J. Tobata, T. Tao, N. Nakada, and S. Takaki: Mater. Sci. Eng. A, 2012, vol. 532, pp. 585–92.

J. Mola and B.C. De Cooman: Scripta Mater., 2011, vol. 65, pp. 834–37.

D. Hauserová, M. Duchek, J. Dlouhý, and Z. Nový: Proc. Eng., 2011, vol. 10, pp. 2961–66.

C.Y. Wang, J. Shi, W.Q. Cao, and H. Dong: Mater. Sci. Eng. A, 2010, vol. 527, pp. 3442–49.

S.C. Hong, J.C. Ahn, S.Y. Nam, S.J. Kim, H.C. Yang, J.G. Speer, and D.K. Matlock: Metall. Mater. Int., 2007, vol. 13, pp. 439–45.

M.J. Santofimia, L. Zhao, Y. Takahama, and J. Sietsma: Mater. Sci. Forum, 2010, vols. 638–642, pp. 3485–90.

C. Kim, A.R. Johnson, and W.F. Hosford: Metall. Trans. A, 1982, vol. 13A, pp. 1595–605.

Y. Tomita: Metall. Trans. A, 1988, vol. 19A, pp. 2513–21.

D. Webster: Metall. Trans. B, 1971, vol. 2B, pp. 1857–62.

W.W. Gerberich, P.L. Hemmings, and V.F. Zackay: Metall. Trans. B, 1971, vol. 2B, pp. 2243–53.

P.J. Jacques: Acta Mater., 2008, vol. 56, pp. 3900–913.

H.K.D.H. Bhadeshia and R.W.K. Honeycombe: Steels: Microstructure and Properties, Butterworth-Heinemann, Burlington, MA, 2006.

X.-Kui Zhu and J.A. Joyce: Eng. Fract. Mech., 2012, vol. 85, pp. 1–46.

J.D. Embury and G. Burger: Proc. of the 7 th International Conference on Strength of Metals and Alloys (ICSMA 7), vol. 3, 1985, pp. 1893–1915.

J.D. Evensen, J. Lereim, and J.D. Embury: Toughness Characterization and Specifications for HSLA and Structural Steels, TMS-AIME, Warrendale, PA, 1976.

ASTM-E399: Standard Test Method for Linear-Elastic Plane-Strain Fracture Toughness KIC of Metallic Materials, 2009.

G. Martin, S.K. Yerra, Y. Bréchet, M. Véron, J.-D. Mithieux, B. Chéhab, L. Delannay, and T. Pardoen: Acta Mater., 2012, vol. 60, pp. 4646–60.

P. Jacques, Q. Furnémont, T. Pardoen, and F. Delannay: Acta Mater., 2001, vol. 49, pp. 139–52.

G. Lacroix, T. Pardoen, and P.J. Jacques: Acta Mater., 2008, vol. 56, pp. 3900–913.

N.H. van Dijk, A.M. Butt, L. Zhao, J. Sietsma, S.E. Offerman, J.P. Wright, and S. van der Zwaag: Acta Mater., 2005, vol. 53, pp. 5439–47.

F.A. McClintock and G.R. Irwin: ASTM STP, 1965, vol. 381, pp. 84–113.

J.E. Srawkey and W.F. Brown: Fracture Toughness Testing, Clearinghouse Fed. Sci. & Technol. Inf., 1965.

W.F. Brown and J.E. Srawley: Plane Strain Crack Toughness Testing of High Strength Metallic Materials, ASTM International, West Conshohocken, PA, 1969.

S.D. Antolovich and B. Singh: Metall. Trans. B, 1971, vol. 2B, pp. 2135–41.

G.R. Chanani, S.D. Antolovich, and W.W. Gerberich: Metall. Trans. B, 1972, vol. 3B, pp. 2661–72.

E.R. Parker and V.F. Zackay: Eng. Fract. Mech., 1973, vol. 5, pp. 147–65.

S.D Antolovich and G.R. Chanani: Eng. Fract. Mech., 1972, vol. 4, pp. 765–76.

Z. Mei and J.W. Morris: Eng. Fract. Mech., 1991, vol. 39, pp. 569–73.

K.V. Sudhakar and E.S. Dwarakadasa: Bull. Mater. Sci., 2000, vol. 23, pp. 193–99.

S. Socrate: Massachusetts Institute of Technology, 1995.

. R.G. Stringfellow: Dissertation Abstracts International (USA) 1992, vol. 52.

H. Bhadeshia: ISIJ Int., 2002, vol. 42, pp. 1059–60.

D.Q. Bai, A. Di Chiro, and S. Yue, Mater. Sci. Forum, 1998, vol. 284–286, pp. 253–62.

H.-S. Yang and H.K.D.H. Bhadeshia: Scripta Mater., 2009, vol. 60, pp. 493–95.

E. Jimenez-Melero, N.H. Van Dijk, L. Zhao, J. Sietsma, S.E. Offerman, J.P. Wright, and S. Van der Zwaag: Scripta Mater., 2007, vol. 56, pp. 421–24.

S.-Jae Lee, S. Lee, and B.C. De Cooman: Scripta Mater., 2011, vol. 64, pp. 649–52.

A. Basuki and E. Aernoudt: J. Mater. Process. Technol., 1999, vol. 89, pp. 37–43.

H.K.D.H. Bhadeshia and D.V. Edmonds: Metall. Sci., 1983, vol. 17, pp. 411–19.

I.B. Timokhina, P.D. Hodgson, and E.V. Pereloma: Metall. Mater. Trans. A, 2004, vol. 35A, pp. 2331–41.

D. Duchateau and M. Guttmann: Acta Metall., 1981, vol. 29, pp. 1291–97.

P.J. Jacques, F. Delannay, and J. Ladrière: Metall. Mater. Trans. A, 2001, vol. 32A, pp. 2759–68.

M. Takahashi and H.K.D.H. Bhadeshia: Mater. Trans., JIM, 1991, vol. 32, pp. 689–96.

D.V. Edmonds, K. He, F.C. Rizzo, B.C. De Cooman, D.K. Matlock, and J.G. Speer: Mater. Sci. Eng. A, 2006, vol. 438, pp. 25–34.

S.K. Putatunda, A.V. Singar, R. Tackett, and G. Lawes: Mater. Sci. Eng. A, 2009, vols. 513–514, pp. 329–39.

A. Kokosza and J. Pacyna: Arch. Mater. Sci., 2008, vol. 31 (2), pp. 87–90.

Acknowledgments

This study is funded by National Science Foundation of China (No. 51174251) and the National Basic Research Program of China (973 Programs No. 2010CB630803). The authors would like to acknowledge Professor David Embury, University of McMaster, for a helpful discussion. The authors acknowledge Professor Nengyun Jin, Shanghai Jiaotong University for language polishing work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted August 7, 2013.

Rights and permissions

About this article

Cite this article

Wu, R., Li, W., Zhou, S. et al. Effect of Retained Austenite on the Fracture Toughness of Quenching and Partitioning (Q&P)-Treated Sheet Steels. Metall Mater Trans A 45, 1892–1902 (2014). https://doi.org/10.1007/s11661-013-2113-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-013-2113-0