Abstract

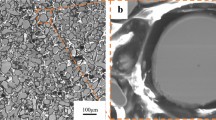

Laser Engineered Net Shaping (LENS™), a solid freeform fabrication technique, was employed for the processing of Fe-based bulk amorphous alloy (Fe BAA) powder on titanium. One and two layers of the Fe BAA were deposited with the same processing parameters. SEM and XRD analyses of the Fe BAA coatings revealed the retention of the feedstock powder’s amorphous nature. The mixing of the feedstock powder in the titanium substrate was very small. A crystalline-amorphous composite microstructure evolved from the laser processing in all types of coatings. The coatings were further laser remelted. The amorphous character was found to increase and the crystallites were found to grow during remelting. The Fe BAA coatings showed higher hardness and smaller wear volume compared to the Ti substrate. A further increase in these properties was observed after laser remelting treatment. During the wear testing in NaCl solution, Ti substrate showed intergranular corrosion, whereas the Fe BAA coatings showed signs of low and localized fretting corrosion in a saline environment. Our results demonstrate that using LENS™, amorphous coatings can be deposited on metallic substrates.

Similar content being viewed by others

References

W. Klement, R.H. Willens, P. Duwez, Nature 187 (1960) 869–70.

R.W. Cahn, Nature 260 (1976) 285.

J.R. Scully, A. Gebert and J.H. Payer (2007), J. Mater. Res., 22, pp 302–13.

Johnson, W.L., (1996), Mater. Sci. Forum, 225-227: 35-50.

Inoue, A., T. Zhang and A. Takeushi (1998), Mater. Sci. Forum, 269-272: 855-64.

A. Inoue, H. Koshiba and T. Itoi (2000), Mater. Sci. Forum 343-346: 81-90.

Schuh, C., T.C. Hufnagel and U. Ramamurthy (2007), Acta Mater. 55(12): 4067-4109.

Balla, V.K. and A. Bandyopadhyay (2010). Surf. Coat. Technol. 205(7): 2661-67.

Basu, A., A.N. Samant, S.P. Harimkar, J.D. Majumdar, I. Manna and N.B. Dahotre, (2008), Surf. Coat. Technol. 202(12): 2623-31.

X.-Y. Li, E. Akiyama, H. Habazaki, A. Kawashima, K. Asami, K. Hashimoto, Corros. Sci., 41 (1999) 1849-69.

A. Inoue, A. Takeuchi, T. Zhang and A. Murakami (1996) IEEE Trans. Magn. 32(5), 4866–71.

Ponnambalam, V., S.J. Poon and J. Shiflet (2011), J. Mater. Res. 19(10): 3046-52.

Li, R., M. Stoica and J. Eckert (2009), Metall. Mater. Trans. 41A: 1640-45.

B.-L. Sheng, H. Koshiba, T. Mizushima and A. Inoue, Met. Trans. JIM, Vol. 41, No. 7 (2000), pp. 873-76.

La, P., Y. Wei, Y. Yang, Y. Bai, X. Lu, X. Guo and H. Wang (2011), Mater. Sci. Eng. A 528(24): 7140-48.

T. Saitoa, H. Takeishi, N. Nakayama (2005) J. Mater. Res., 20(3), 563.

Nishiyama, N., K. Takenaka, H. Miura, N. Saidoh, Y. Zeng and A. Inoue (2012), Intermetallics 30: 19-24.

L.A. Davis, Y.T. Yeow, and P.M. Anderson, J. Appl. Phys. 53, 4834–37 (1982).

A. Singh, S. Paital, A. Andapally, N. Dahotre, S. Harimkar (2012), Adv. Eng. Mater., 14(6), 400–407.

C. Zhang, R.Q. Guo, Y. Yang, Y. Wu, L. Liu, Electrochim. Acta 56 (2011) 6380–88.

X. Zhou, L. Hu, Q. Chen and X. Hua, Adv. Mater. Res. 189–193 (2011), pp 428-32.

H. Ma, W. Wang, J. Zhang, G. Li, C. Cao, and H. Zhang (2011) J. Mater. Sci. Technol., vol. 27(12), 1169.

A. Inoue, A. Katsuya, K. Amiya, T. Masumoto, Met. Trans. JIM, Vol. 36, No. 7 (1995), pp. 802-09.

Y. Zhang, N. Wanderka, U. Czubayko, F. Zhu, W. Wollenberger (2000), Mater. Sci. Forum, 343–346, pp. 371-76.

Li, S., G.Q. Xie, Louzguine-Luzgin D.V., Sato M and Inoue A (2012), J. Alloys Compd. 536: S315-S318.

X.L. Wu, Y.S. Hong, Surf. Coat. Technol. 132 (2000) 194.

P. Zhang, H. Yan, P. Xu, Q. Lu, C. Li, Z. Yu, Surf. Coat. Technol. 206 (2012) 4981–87.

R. Li, Z. Li, J. Huang, Y. Zhu, Appl. Surf. Sci. 258 (2012) 7956–61.

B. Chen, Y. Li, Y. Cai, R. Li, S. Pang, T. Zhang, J. Alloys Compd. 511 (2012) 215–20.

A. Bandyopadhyay, B.V. Krishna, W. Xue, S. Bose (2009) J. Mater. Sci. Mater. Med. 20, S29–S34.

K. Amiya, A. Urata, N. Nishiyama and A. Inoue (2004) Mater. Trans., 45(4), 1214–18.

S. Pang, T. Zhang, K. Asami, and A. Inoue (2002), J. Mater. Res., 17(3), 701–04.

D. Huang, R. Li, L. Huang, V. Ji, T. Zhang, Intermetallics 19 (2011) 1385–89.

X.J. Gu, S.J. Poon, G. Shiflet (2007) J. Mater. Res., 22(2), 344.

Z. Zheng, W. Lu, H. Dingyong, L. Yanbo, Z. Guangzhen (2011) Rare Met. Mater. Eng., 40(3): 160–65.

Q.J. Chen, J. Shen, D.L. Zhang, H.B. Fan, and J.F. Sun (2007) J. Mater. Res., 22(2), pp. 358–63.

L. Wang, Y. Chao (2012) Mater. Lett. 69, 76–78.

G.C. Lavorato, G. Fiore, A. Castellero, M. Baricco, J.A. Moya, Physica B 407 (2012) 3192–95.

C. Jiang, J. Pei, J. Hao (2011) Adv. Mater. Res., 150, 881–84.

Demetriou, M.D., G. Duan C. Veazey, K. De Blauwe and W.L. Johnson (2007), Scripta Mater. 57(1): 9–12.

Peker, A. and W.L. Johnson (1993). Appl. Phys. Lett. 63(17): 2342–44.

Hofmann, D.C., J.Y. Suh, A. Wiest, G. Duan, M.L. Lind, M.D. Demetriou and W.L. Johnson (2008), Nature 451(7182): 1085-89.

Schroers, J., W. Johnson (2004) Phys. Rev. Lett. 93(25), 255506.

Ramamurty, U., S. Jana, Y. Kawamura and K. Chattopadhyay. (2005), Acta Mater. 53(3): 705-717.

Ramamurty, U., N. Nagendra and Y. Li (2001), Mater. Sci. Forum 360-362: 61-66.

Narayan, R.L., K. Boopathy, I. Sen, D. C. Hofmann and U. Ramamurty (2010), Scripta Mater. 63(7): 768-71.

Jin, H.W., R. Ayer and J.Y. Koo (2011), J. Mater. Res. 22(02): 264-73.

Das, K., A. Bandyopadhyay and Y.M. Gupta (2005), Mater. Sci. Eng. A 394(1-2): 302-311.

F. Luborsky, J.J. Becker, J. Walter, D.L. Martin (1980) IEEE Trans. Magn. 1(3), 521.

Bhowmick, R., B. Majumdar, D. K. Misra, U. Ramamurty and K. Chattopadhyay (2007), J. Mater. Sci. 42(22): 9359-65.

Louzguine-Luzgin, D.V., L.V. Louzguina-Luzgina, H. Kato and A. Inoue (2005), Acta Mater. 53(7): 2009-017.

G. Mastrogiacomo, J. Kradolfer, and J.F. Löffler (2006) J. Appl. Phys. 99, 023908.

A. Inoue, T. Zhang, A. Takeuchi, W. Zhang, Met. Trans. JIM, Vol. 37, No. 4 (1996), pp. 636-40.

A. Inoue, A. Makino, T. Mizushima, J. Magn. Magn. Mater. 215-216 (2000) 246-52.

A. Inoue and A. Takeuchi (1995) IEEE Trans. Magn. 31(6), 3605–07.

Movahedi, B., M.H. Enayati and C.C. Wong (2010), J. Therm. Spray Technol. 19(5): 1093-99.

P. Hess, S.J. Poon, G. Shiflet, R.H. Dauskadrt (2005) J. Mater. Res., 20(4), 783.

K. Miyoshi, D.H. Buckley (1983) ASLE Trans. 27(4), 295.

J. Jayaraj, Y.C. Kim, K.B. Kim, H.K. Seok, E. Fleury, Sci. Technol. Adv. Mater. 6 (2005) 282–89.

D.T.A. Matthews, V. Ocelík, D. Branagan, J.Th.M. de Hosson, Surf. Coat. Technol. 203 (2009) 1833–43.

Acknowledgments

The authors acknowledge the W.M. Keck Foundation’s financial support to establish the Biomedical Materials Research Lab at WSU. Dr. Daniel J. Branagan of The NanoSteel Company Inc. is gratefully acknowledged for providing the NSSHS7574 glass-forming alloy powder used in the current investigation.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted January 31, 2013.

Rights and permissions

About this article

Cite this article

Sahasrabudhe, H., Dittrick, S.A. & Bandyopadhyay, A. Laser Processing of Fe-Based Bulk Amorphous Alloy Coatings on Titanium. Metall Mater Trans A 44, 4914–4926 (2013). https://doi.org/10.1007/s11661-013-1846-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-013-1846-0