Abstract

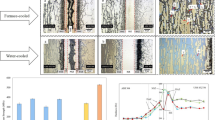

Nickel-based filler alloy with a liquidus temperature of 1024 °C was used for transient liquid phase (TLP) bonding of A564-630 martensitic precipitation hardening stainless steel. TLP experiments were carried out at a constant temperature of 1050 °C for different times between 30 to 90 min employing 75 μm thick filler metal to achieve the best TLP parameters. A Ni coating of 10 μm was coated to the base materials to compare the joints with and without coating. The effect of bonding conditions on the microstructure and mechanical properties of samples was investigated. The isothermal solidification was achieved after 60 min of bonding time. The results showed that bond shear strength increased with increasing the TLP time. The Ni coating improved the microstructure and shear strength of the joint and the Ni-coated base metal TLP bonded at 1050 °C for 90 min showed lap-shear strength of maximum 461 MPa. By comparing the results of the line scan analysis and the hardness profile, it is concluded that with increasing the TLP time, a more uniform distribution of alloying elements and hardness profile across the joint region was achieved.

Similar content being viewed by others

References

C.R. Das, H.C. Dey, G. Srinivasan, S.K. Albert, A.K. Bhaduri, and A. Dasgupta, Weldability of 17-4PH Stainless Steel in Overaged Heat Treated Condition, Sci. Technol. Weld. Join., 2006, 11(5), p 502–508

C.N. Hsiao, C.S. Chiou, and J.R. Yang, Aging Reactions in a 17-4 PH Stainless Steel, Mater. Chem. Phys., 2002, 74(2), p 134–142

M. Bahrami Balajaddeh and H. Naffakh-Moosavy, Pulsed Nd:YAG Laser Welding of 17-4 PH Stainless Steel: Microstructure, Mechanical Properties, and Weldability Investigation, Opt. Laser Technol., 2019, 119, p 105651

A. Ziewiec, A. Zielińska-Lipiec, and E. Tasak, Microstructure of Welded Joints of X5CrNiCuNb 16-4 (17-4 PH) Martensitic Stainlees Steel After Heat Treatment, Arch. Metall. Mater., 2014, 59(3), p 965–970

ASTM-A564, Standard Specification for Hot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and Shapes, ASTM International, West Conshohocken, 2010, p 1–7

W. Liu, J. Ma, M.M. Atabaki, R. Pillai, B. Kumar, U. Vasudevan, H. Sreshta, and R. Kovacevic, Hybrid Laser-arc Welding of 17-4 PH Martensitic Stainless Steel, Lasers Manuf. Mater. Process., 2015, 2(2), p 74–90

L. Zai, C. Zhang, Y. Wang, W. Guo, D. Wellmann, X. Tong, and Y. Tian, Laser Powder Bed Fusion of Precipitation-Hardened Martensitic Stainless Steels: A Review, Metals (Basel), 2020, 10(2), p 1–25

S. Vunnam, A. Saboo, C. Sudbrack, and T.L. Starr, Effect of Powder Chemical Composition on the As-Built Microstructure of 17-4 PH Stainless Steel Processed by Selective Laser Melting, Addit. Manuf., 2019, 30, p 100876

S. Hadibeyk, B. Beidokhti, and S.A. Sajjadi, Effect of Bonding Time and Homogenization Heat Treatment on the Microstructure and Mechanical Properties of the Transient Liquid Phase Bonded Dissimilar GTD-111/FSX-414 TLP Superalloys, J. Alloys Compd., 2018, 731, p 929–935

E. Norouzi, M. Shamanian, M. Atapour, and B. Khosravi, Diffusion Brazing of Ti-6Al-4V and AISI, 304: An EBSD Study and Mechanical Properties, J. Mater. Sci., 2017, 52(20), p 12467–12475

G.O. Cook and C.D. Sorensen, Overview of Transient Liquid Phase and Partial Transient Liquid Phase Bonding, J. Mater. Sci., 2011, 46(16), p 5305–5323

A. Rabinkin, E. Wenski, and A. Ribaudo, Brazing Stainless Steel Using a New MBF-Series of Ni-Cr-B-Si Amorphous Brazing Foils, Weld. J., 1998, 77(2), p 66s–75s

D.M. Jacobson and G. Humpston, Brazing, ASM International, Materials Park, 2005

L.X. Zhang, Z. Sun, Q. Xue, M. Lei, and X.Y. Tian, Transient Liquid Phase Bonding of IC10 Single Crystal with GH3039 Superalloy Using BNi2 Interlayer: Microstructure and Mechanical Properties, Mater. Des., 2016, 90, p 949–957

S. Shakerin, V. Maleki, S.A. Ziaei, and H. Omidvar, Microstructural and Mechanical Assessment of Transient Liquid Phase Bonded Commercially Pure Titanium, Can. Metall. Q., 2017, 56(3), p 1–8

J. Ma, M.M. Atabaki, W. Liu, R. Pillai, B. Kumar, U. Vasudevan, and R. Kovacevic, Laser-Based Welding of 17-4 PH Martensitic Stainless Steel in a Tubular Butt Joint Configuration with a Built-in Backing Bar, Opt. Laser Technol., 2016, 82, p 38–52

D.W. Deng, C.P. Zhang, R. Chen, and H.F. Xia, Microstructure and Microhardness of 17-4PH Deposited with Cobased Alloy Hardfacing Coating, Phys. Procedia, 2013, 50, p 177–184

R.K. Shiue, S.K. Wu, and J.Y. Shiue, Infrared Brazing of Ti-6Al-4V and 17-4 PH Stainless Steel with (Ni)/Cr Barrier Layer(s), Mater. Sci. Eng., A, 2008, 488(2), p 186–194

F.Z. Wang, Q.Z. Wang, B.H. Yu, B.L. Xiao, and Z.Y. Ma, Interface Structure and Mechanical Properties of Ti(C, N)-Based Cermet and 17–4PH Stainless Steel Joint Brazed with Nickel-Base Filler Metal BNi-2, J. Mater. Process. Technol., 2011, 211(11), p 1804–1809

https://metglas.com/brochures. Accessed 20 Dec 2019

F. Arhami, S.E. Mirsalehi, A. Sadeghian, and M.H. Johar, The Joint Properties of a High-Chromium Ni-Based Superalloy Made by Diffusion Brazing: Microstructural Evolution, Corrosion Resistance and Mechanical Behavior, J. Manuf. Process., 2019, 37, p 203–211

M.J. Cieslak, T.J. Headley, G.A. Knorovsky, A.D. Romig, and T. Kollie, A Comparison of the Solidification Behavior of INCOLOY 909 and INCONEL 718, Metall. Trans. A, 1990, 21(1), p 479–488

T. Venkateswaran, V. Xavier, D. Sivakumar, B. Pant, and G.D. Ram, Brazing of Stainless Steels Using Cu-Ag-Mn-Zn Braze Filler: Studies on Wettability, Mechanical Properties, and Microstructural Aspects, Mater. Des., 2017, 121, p 213–228

R. Bakhtiari and A. Ekrami, Transient Liquid Phase Bonding of FSX-414 Superalloy at the Standard Heat Treatment Condition, Mater. Charact., 2012, 66, p 38–45

Y. Luo, Q. Zhang, W. Jiang, Y. Zhang, M. Hao, and S.T. Tu, The Microstructure, Mechanical Properties and Fracture Behavior of Hastelloy C276-BNi2 Brazed Joint, Mater. Des., 2017, 115, p 458–466

S. Ghaderi, F. Karimzadeh, and A. Ashrafi, Evaluation of Microstructure and Mechanical Properties of Transient Liquid Phase Bonding of Inconel 718 and Nano/ultrafine-Grained 304L Stainless Steel, J. Manuf. Process., 2020, 49, p 162–174

M. Pouranvari, A. Ekrami, and A.H. Kokabi, TLP Bonding of Cast IN718 Nickel Based Superalloy: Process Microstructure Strength Characteristics, Mater. Sci. Eng., A, 2013, 568, p 76–82

D.Q. Sun, X.Y. Gu, and W.H. Liu, Transient Liquid Phase Bonding of Magnesium Alloy (Mg-3Al-1Zn) Using Aluminium Interlayer, Mater. Sci. Eng., A, 2005, 391, p 29–33

H. Nami, A. Halvaee, and H. Adgi, Transient Liquid Phase Diffusion Bonding of Al/Mg2Si Metal Matrix Composite, Mater. Des., 2011, 32(7), p 3957–3965

V. Jalilvand, H. Omidvar, M.R. Rahimipour, and H.R. Shakeri, Influence of Bonding Variables on Transient Liquid Phase Bonding Behavior of Nickel Based Superalloy IN-738LC, Mater. Des., 2013, 52, p 36–46

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Moradi, M.J., Emadoddin, E. & Omidvar, H. The Joint Properties of A564-630 Stainless Steel Made by Transient Liquid Phase Bonding: Microstructural and Mechanical Strength Evaluation. J. of Materi Eng and Perform 29, 4745–4753 (2020). https://doi.org/10.1007/s11665-020-04962-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04962-z