Abstract

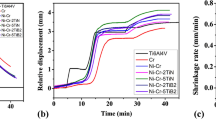

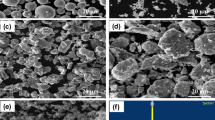

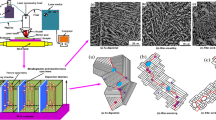

This work presents the densification behavior, microstructural features, microhardness, and wear property of in situ TiN/Ti5Si3 composite parts prepared by a novel Selective Laser Melting (SLM) process. The occurrence of balling phenomenon at a low laser energy density combined with a high scan speed and the formation of thermal cracks at an excessive laser energy input generally decreased densification rate. The in situ-formed TiN reinforcing phase experienced a successive morphological change: an irregular polyangular shape—a refined near-round shape—a coarsened dendritic shape, as the applied laser energy density increased. The variations in liquid-solid wettability and intensity of Marangoni convection within laser molten pool accounted for the different growth mechanisms of TiN reinforcement. The TiN/Ti5Si3 composite parts prepared under the optimal SLM conditions had a near-full 97.7 pct theoretical density and a uniform microhardness distribution with a significantly increased average value of 1358.0HV0.3. The dry sliding wear tests revealed that a considerably low friction coefficient of 0.19 without any apparent fluctuation and a reduced wear rate of 6.84 × 10−5mm3/Nm were achieved. The enhanced wear resistance was attributed to the formation of adherent strain-hardened tribolayer covered on the worn surface.

Similar content being viewed by others

References

R. Mitra: Metall. Mater. Trans. A, 1998, vol. 29A, pp. 1629–41.

R. Mitra, V.V. Rama Rao: Metall. Mater. Trans. A, 1998, vol. 29A, pp. 1665–75.

J.H. Shim, J.S. Byun, and Y.W. Cho: J. Am. Ceram. Soc., 2004, vol. 87, pp. 1853–58.

L.J. Wang, W. Jiang, C. Qin, and L.D. Chen: J. Mater. Sci., 2006, vol. 41, pp. 3831–35.

I.J. Shon, H.C. Kim, D.H. Rho, and Z.A. Munir: Mater. Sci. Eng. A, 1999, vol. 269, pp. 129–35.

J.L. Li, D.L. Jiang, and S.H. Tan: J. Eur. Ceram. Soc., 2002, vol. 22, pp. 551–58.

S.C. Tjong: Adv. Eng. Mater., 2007, vol. 9, pp. 639–52.

A. Gåård, P. Krakhmalev, and J. Bergström: J. Alloys Compd., 2006, vol. 421, pp. 166–71.

D.D. Gu, Y.C. Hagedorn, W. Meiners, K. Wissenbach, and R. Poprawe: Surf. Coat Technol., 2011, vol. 205, pp. 3285–92.

J.F. Shackelford and W. Alexander: CRC Materials Science and Engineering Handbook, 3rd ed., CRC Press, Boca Raton, FL, 2000.

M.A. Thein, L. Lu, and M.O. Lai: Mater. Sci. Eng. A, 2010, vol. 528, pp. 239–46.

V. Abbasi Chianeh, H.R. Madaah Hosseini, and M. Nofar: J. Alloys Compd., 2009, vol. 473, pp. 127–32.

C.L. Yeh and G.S. Teng: J. Alloys Compd., 2007, vol. 429, pp. 126–32.

D. Horvitz and I. Gotman: Acta Mater., 2002, vol. 50, pp. 1961–71.

Y.F. Yang, H.Y. Wang, J. Zhang, R.Y. Zhao, Y.H. Liang, and Q.C. Jiang: J. Am. Ceram. Soc., 2008, vol. 91, pp. 2736–39.

S. Kumar, V. Subramaniya Sarma, and B.S. Murty: Metall. Mater. Trans. A, 2010, vol. 41A, pp. 242–54.

R. Hadian, M. Emamy, and J. Campbell: Metall. Mater. Trans. B, 2009, vol. 40B, pp. 822–32.

B. Zheng, T. Topping, J.E. Smugeresky, Y. Zhou, A. Biswas, D. Baker, and E.J. Lavernia: Metall. Mater. Trans. A, 2010, vol. 41A, pp. 568–73.

B. Zheng, J.E. Smugeresky, Y. Zhou, D. Baker, and E.J. Lavernia: Metall. Mater. Trans. A, 2008, vol. 39A, pp. 1196–205.

B.V. Krishna, S. Bose, and A. Bandyopadhyay: Metall. Mater. Trans. A, 2007, vol. 38A, pp. 1096–1103.

W.P. Liu and J.N. DuPont: Metall. Mater. Trans. A, 2005, vol. 36A, pp. 3397–406.

R. Banerjee, A. Genç, P.C. Collins, and H.L. Fraser: Metall. Mater. Trans. A, 2004, vol. 35A, pp. 2143–52.

J.P. Kruth, G. Levy, F. Klocke, and T.H.C. Childs: CIRP Ann. Manuf. Technol., 2007, vol. 56, pp. 730–59.

D. Bourell, M. Wohlert, N. Harlan, S. Das, and J. Beaman: Adv. Eng. Mater., 2002, vol. 4, pp. 663–69.

S. Das: Adv. Eng. Mater., 2003, vol. 5, pp. 701–11.

A. Simchi, F. Petzoldt, and H. Pohl: Int. J. Powder Metall., 2001, vol. 37, pp. 49–61.

S. Kumar and J.P. Kruth: Mater. Des., 2010, vol. 31, pp. 850–56.

D.D. Gu and W. Meiners: Mater. Sci. Eng. A, 2010, vol. 527, pp. 7585–92.

D.D. Gu and Y.F. Shen: Acta Metall. Sin., 2010, vol. 46, pp. 761–68.

D.D. Gu and Y.F. Shen: J. Alloys Compd., 2009, vol. 473, pp. 107–15.

P. Fischer, V. Romano, H.P. Weber, N.P. Karapatis, E. Boillat, and R. Glardon: Acta Mater., 2003, vol. 51, pp. 1651–62.

A. Simchi and H. Pohl: Mater. Sci. Eng. A, 2003, vol. 359, pp. 119–28.

Q.L. Huang, J. Cai, W. Pan, J. Chen, and J. Lian: Mater. Lett., 1997, vol. 31, pp. 221–25.

I. Barin: Thermochemical Data of Pure Substances, 3rd ed., VCH, New York, NY, 1993.

D.D. Gu, Y.F. Shen, and Z.J. Lu: Mater. Lett., 2009, vol. 63, pp. 1577–79.

K. Arafune and A. Hirata: J. Cryst. Growth, 1999, vol. 197, pp. 811–17.

X.B. Zhou and J.Th.M. De Hosson: Acta Mater., 1996, vol. 44, pp. 421–26.

Z.F. Yuan, J.J. Ke, and J. Li: Surface Tension of Metals and Alloys, 1st ed., Science Press, Beijing, China, 2006.

I. Takamichi and I.L.G. Roderick: The Physical Properties of Liquid Metals, 1st ed., Clarendon Press, Oxford, UK, 1993.

H.J. Niu and I.T.H. Chang: Scripta Mater., 1999, vol. 41, pp. 1229–34.

H.H. Zhu, L. Lu, and J.Y.H. Fuh: Mater. Sci. Eng. A, 2004, vol. 371, pp. 170–77.

P. Mercelis and J.P. Kruth: Rapid Prototyping J., 2006, vol. 12, pp. 254–65.

B.S. Kim, S.J. Hong, and D.J. Kim: Metall. Mater. Int., 2010, vol. 16, pp. 565–68.

K. Tsukuma, M. Shimada, and M. Koizumi: Ceram. Bull., 1981, vol. 60, pp. 910–12.

M.F. Wani, Z.A. Khan, and M. Hadfield: J. Adv. Res. Mech. Eng., 2010, vol. 1, pp. 52–59.

A. Jain, B. Basu, B.V. Manoj, K. Harshavardhan, and J. Sarkar: Acta Mater., 2010, vol. 58, pp. 2313–23.

Acknowledgments

One author (D.D.G.) gratefully appreciates the fellowship of the Alexander von Humboldt Foundation for sponsoring the research stay in Germany. Financial supports from the National Natural Science Foundation of China (No. 51054001 and No. 51104090), the Aeronautical Science Foundation of China (No. 2010ZE52053), the Natural Science Foundation of Jiangsu Province (No. BK2009374), and the NUAA Research Funding (No. NS2010156) are appreciated.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 13, 2011.

Rights and permissions

About this article

Cite this article

Gu, D., Hong, C. & Meng, G. Densification, Microstructure, and Wear Property of In Situ Titanium Nitride-Reinforced Titanium Silicide Matrix Composites Prepared by a Novel Selective Laser Melting Process. Metall Mater Trans A 43, 697–708 (2012). https://doi.org/10.1007/s11661-011-0876-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-011-0876-8