Abstract

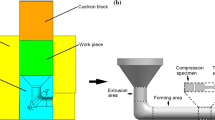

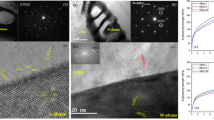

This work mainly investigated the microstructure and mechanical properties of Mg-Zn-Y-Zr alloys with Zn/Y ratios of 5 and 10. An X-ray diffraction (XRD) analysis indicated that the two alloys were mainly composed of an icosahedral phase (I-phase) and α-Mg matrix. For the alloy with a Zn/Y ratio of 10, however, the diffraction peaks of the I-phase were stronger. Microstructure observation showed that the I-phase preferentially existed in the form of I-phase/α-Mg matrix interdendritic eutectic pockets at grain boundaries. Moreover, when the Zn/Y ratio was increased 2 times, the volume fraction of the I-phase in the α-Mg matrix increased 1.5 times and a tiny Mg7Zn3 phase formed. Energy-dispersive spectroscopy (EDS) mapping and electron probe microanalysis (EPMA) results suggested that the chemical composition of the I-phase was not a constant value. Computer-aided cooling curve analysis (CA-CCA) indicated that, for the alloy with a Zn/Y ratio of 5, formation of the I-phase relied on the W-phase transformation and the eutectic reaction of the residual melt. However, the I-phase formation for the alloy with a Zn/Y ratio of 10 depended on the eutectic reaction of the melt. Tensile tests indicated that the mechanical properties of the two as-cast alloys were poor. After hot extrusion processing, the mechanical properties of the alloy with a Zn/Y ratio of 10 were noticeably increased. The ultimate tensile strength (UTS) and elongation to failure reached 320 MPa and 13 pct, respectively.

Similar content being viewed by others

Notes

PHILIPS is a trademark of Philips Electronic Instruments Corp., Mahwah, NJ.

References

Z.P. Luo, S.Q. Zhang, Y.L. Tang, and D.S. Zhao: Scripta Metall. Mater., 1993, vol. 28, pp. 1513–18.

A Niikura, A.P. Tsai, A. Innoe, and T. Matsumoto: Philos. Mag. Lett., 1994, vol. 69, pp. 351–55.

A.P. Tsai, A. Niikura, A. Innoe, T. Matsumoto, K. Tsuda, and M. Tanaka: Philos. Mag. Lett., 1994, vol. 70, pp. 169–75.

A.P. Tsai, T. Matsumoto, and A. Niikura: Philos. Mag. A, 2000, vol. 80, pp. 1043–54.

J.B. Ok, I.J. Kim, S. Yi, T.W. Kim, and D.H. Kim: Philos. Mag. A, 2003, vol. 83, pp. 2359–69.

D.H. Bae, Y. Kim, and I.J. Kim: Mater. Lett., 2006, vol. 60, pp. 2190–93.

D.H. Bae, M.H. Lee, K.T. Kim, W.T. Kim, and D.H. Kim: J. Alloys Compd., 2002, vol. 342, pp. 445–50.

A. Singh, M. Nakamura, M. Watanabe, A. Kato, and A.P. Tsai: Scripta Mater., 2003, vol. 49, pp. 417–22.

F.S. Pierce, S.J. Poon, and Q. Guo: Science, 1993, vol. 261, pp. 737–39.

J.M. Dubois, P. Plaindoux, E. Berlin-Ferre, N. Tamura, and D.J. Sordelet: Proc. 6th Int. Conf. Quasicrystals, World Scientific, Singapore, 1997.

E.S. Park, S. Yi, J.B. Ok, D.H. Bae, and W.T. Kim: Proc. MRS Fall Meeting, Boston, MA, 2001.

D.K. Xu, L. Liu, Y.B. Xu, and E.H. Han: Scripta Mater., 2007, vol. 57, pp. 285–88.

J.Y. Lee, H.K. Lim, D.H. Kim, W.T. Kim, and H.K. Do: Mater. Sci. Eng., A, 2007, vols. 449–451, pp. 987–90.

A. Singh, M. Watanabe, A. Kato, and A.P. Tsai: Mater. Sci. Eng., A, 2004, vol. 385, pp. 382–96.

D.K. Xu, W.T. Tang, L. Liu, Y.B. Xu, and E.H. Han: J. Alloys Compd., 2007, vol. 432, pp. 129–34.

D.K. Xu, L. Liu, Y.B. Xu, and E.H. Han: J. Alloys Compd., 2006, vol. 426, pp. 155–61.

J.Y. Lee, D.H. Kim, H.K. Lim, and H. Kim: Mater. Lett., 2005, vol. 59, pp. 3801–05.

X.Q. Zeng, Y. Zhang, C. Lu, W.J. Ding, Y.X. Wang, and Y.P. Zhu: J. Alloys Compd., 2005, vol. 395, pp. 213–19.

D.K. Xu, L. Liu, Y.B. Xu, and E.H. Han: Mater. Sci. Eng., A, 2007, vol. 443, pp. 248–56.

Y. Zhang, X.Q. Zeng, L.F. Liu, C. Lu, H.T. Zhou, Q. Li, and Y.P. Zhu: Mater. Sci. Eng., A, 2004, vol. 373, pp. 320-27.

Structure and Properties of Engineering Alloys, W.F. Smith, ed., McGraw-Hill, New York, NY, 1993, p. 542.

D.K. Xu, W.T. Tang, L. Liu, Y.B. Xu, and E.H. Han: J. Alloys Compd., 2008, vol. 461, pp. 248–52.

S. Yi, E.S. Park, J.B. Ok, W.T. Kim, and D.H. Kim: Mater. Sci. Eng., A, 2001, vol. 300, pp. 312–15.

M.F. Horstemeyer and N. Yang: Acta Mater., 2004, vol. 52, pp. 1327–36.

S.M. Liang, R.S. Chen, J.J. Blandin, M. Suery, and E.H. Han: Mater. Sci. Eng., A, doi:10.1016/j.msea.2007.07.025.

D. Emadi, L.V. Whiting, S. Nafisi, and R. Ghomashchi: J. Therm. Anal. Calorim., 2005, vol. 81, pp. 235–42.

K.G. Upadhya, D.M. Stefanescu, K. Lieu, and D.P. Yeager: AFS Trans., 1989, vol. 97, pp. 61–66.

S. Thompson, S.L. Cockcroft, and M.A. Wells: Mater. Sci. Technol., 2004, vol. 20, pp. 194–200.

W.T. Kierkus and J.H. Solokowski: AFS Trans., 1999, vol. 107, pp. 161–67.

D. Mirkovic and R. Schmid-Fetzer: Z. Metallkd., 2006, vol. 97, pp. 119–29.

E. Fras, W. Kapturkiewicz, A. Burbielko, and H.F. Lopez: AFS Trans., 1993, vol. 101, pp. 505–11.

D.K. Xu, L. Liu, Y.B. Xu, and E.H. Han: Acta Mater., 2008, vol. 56, pp. 985–94.

D.H. Bae, S.H. Kim, D.H. Kim, and W.T. Kim: Acta Mater., 2002, vol. 50, pp. 2343–56.

Y. Brechet, J.D. Embury, S. Tao, and L. Luo: Acta Metall Mater., 1991, vol. 39, pp. 1781–86.

D.J. Lloyd: Acta Metall Mater., 1991, vol. 39, pp. 59–71.

A. Langsdorf, F. Ritter, and W. Assmus: Philos. Mag. Lett., 1997, vol. 75, pp. 381–87.

N. Lebrun, A. Stamou, C. Baetzner, J. Robinson, and A. Pisch: in Ternary Alloys, G. Effenberg, F. Aldinger, and P. Rogl, eds., Materials Science International Services, Stuttgart, 2001, vol. 18, p. 702.

Y. Zhang, S. Yu, X. Zhu, and Y. Luo: J. Non-Cryst. Solids, 2008, vol. 354, pp. 1564–68.

G. Shao, V. Varsni, and Z. Fan: CALPHAD, 2006, vol. 30, pp. 286–95.

R.J. Arsenault, L. Wang, and C.R. Feng: Acta Metall. Mater., 1991, vol. 39, pp. 47–57.

W.S. Miller and F.J. Humphreys: Scripta Metall. Mater., 1991, vol. 25, pp. 33–38.

R.M. Aikin, Jr., and L. Christodoulou: Scripta Metall. Mater., 1991, vol. 25, pp. 9–14.

J.W. Luster, M. Thumann, and R. Baumann: Mater. Sci. Technol., 1993, vol. 9, pp. 853–62.

M. Mabuchi and K. Higashi: Acta Mater., 1996, vol. 44, pp. 4611–18.

P. Dobroň, J. Bohlen, F. Chmelík, P. Lukáč, D. Letzig, and K.U. Kainer: Mater Sci. Eng., A, 2007, vol. 462, pp. 307–10.

Acknowledgments

This work was supported by a National Science Fund of China project under Grant No. 50431020 and by a National Basic Research Program of China (973 Program) project under Grant No. 2007CB613704. The authors thank S.M. Liang and Z.H. Huang for performing some of the CA-CCA.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted November 13, 2007.

Rights and permissions

About this article

Cite this article

Xu, D.K., Han, EH., Liu, L. et al. Influence of Higher Zn/Y Ratio on the Microstructure and Mechanical Properties of Mg-Zn-Y-Zr Alloys. Metall Mater Trans A 40, 1727–1740 (2009). https://doi.org/10.1007/s11661-009-9817-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-009-9817-1