Abstract

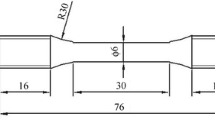

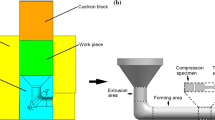

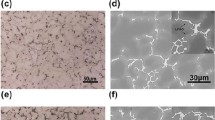

In the present work, Zn–(0–1)Mg (wt%) alloys were prepared by casting and indirect extrusion at 200 and 300 °C, respectively. With Mg addition, both the size and amount of second phase Mg2Zn11 increased, and the equiaxed grains were significantly refined. The extrusion temperature had little influence on Mg2Zn11, but the grains were refined at low extrusion temperature. For the alloys extruded at 200 °C, as Mg content increased, the tensile yield strength (TYS) increased from 64 MPa for pure Zn to 262 MPa for Zn–1Mg; the elongation increased from 14.3% for pure Zn to 25% for Zn–0.02Mg and then decreased to 5% for Zn–1Mg. For the alloys extruded at 300 °C, as Mg content increased, the TYS increased from 67 MPa for pure Zn to 252 MPa for Zn–1Mg, while the elongation decreased from 11.7% to 2%. The alloy extruded at 200 °C exhibited higher TYS and elongation than the corresponding alloy extruded at 300 °C. The combination of grain refinement and second phase Mg2Zn11 contributed to the improvement in the TYS, and the grain refinement played a major role in strengthening alloy. Zn–0.02Mg and Zn–0.05Mg alloys extruded at 200 °C show a mixture of cleavage and ductile fracture corresponding to higher elongation, while the other alloys show cleavage fracture.

Similar content being viewed by others

References

R. Hansch, R.R. Mendel, Curr. Opin. Plant Biol. 129, 259 (2009)

L. Rink, Zn in Human Health (IOS Press, Amsterdam, 2011)

D. Vojtech, J. Kubasek, J. Capek, I. Pospisilova, Mater. Technol. 49, 877 (2015)

D.E. Talbot, J.D. Talbot, Corrosion Science and Technology (CRC Press, Boca Raton, 2007)

P.K. Bowen, J. Drelich, J. Goldman, Adv. Mater. 25, 2577 (2013)

D. Vojtech, J. Kubásek, J. Šerák, P. Novák, Acta Biomater. 7, 3515 (2011)

J. Kubasek, D. Vojtech, E. Jablonska, I. Pospisilova, J. Lipov, T. Ruml, Mater. Sci. Eng., C 58, 24 (2016)

X.W. Liu, J.K. Sun, F.Y. Zhou, Y.H. Yang, R.C. Chang, K.J. Qiu, Z.J. Pu, L. Li, Y.F. Zheng, Mater. Des. 94, 95 (2016)

X.W. Liu, J.K. Sun, Y.H. Yang, F.Y. Zhou, Z.J. Pu, L. Li, Y.F. Zheng, Mater. Lett. 165, 242 (2016)

J. Kubasek, I. Pospisilova, D. Vojtech, E. Jablonska, T. Ruml, Mater. Technol. 48, 623 (2014)

H. Gong, K. Wang, R. Strich, J.G. Zhou, J. Biomed. Mater. Res. B 103, 1632 (2015)

H.F. Li, H.X. Xie, Y.F. Zheng, Y. Cong, F.Y. Zhou, K.J. Qiu, X. Wang, S.H. Chen, L. Huang, L. Tian, L. Qin, Sci. Rep. 5, 10719 (2015)

H.F. Li, H.T. Yang, Y.F. Zheng, F.Y. Zhou, K.J. Qiu, X. Wang, Mater. Des. 83, 95 (2015)

N.S. Murni, M.S. Dambatta, S.K. Yeap, G.R.A. Froemming, H. Hermawan, Mater. Sci. Eng., C 49, 560 (2015)

P. Ghosh, M. Mezbahul-Islam, M. Medraj, CALPHAD 36, 28 (2012)

J.H. Liu, C.X. Huang, S.D. Wu, Z.F. Zhang, Mater. Sci. Eng., A 409, 117 (2008)

F.J. Humphreys, M. Hatherly, Recrystallization and Related Annealing Phenomena, 2nd edn. (Elsevier Science, New York, 2004)

N.G. Ross, M.R. Barnet, A.G. Beer, Mater. Sci. Eng., A 619, 238 (2014)

B.Q. Shi, R.S. Chen, W. Ke, J. Alloys Compd. 509, 3357 (2011)

L. Cao, R.S. Chen, E.H. Han, J. Alloys Compd. 472, 234 (2009)

Y. Chen, N. Gao, G. Sha, S.P. Ringer, M.J. Starink, Acta Mater. 109, 202 (2016)

Z.L. Liu, D. Qiu, F. Wang, J.A. Taylor, M.X. Zhang, Metall. Mater. Trans. A 47, 830 (2016)

R. Armstrong, I. Codd, R.M. Douthwaite, N.J. Petch, Philos. Mag. 7, 45 (1962)

M. Mabuchi, K. Higashi, Acta Mater. 44, 4611 (1996)

J.W. Liu, X.D. Peng, M.L. Li, G.B. Wei, W.D. Xie, Y. Yang, Mater. Sci. Eng., A 655, 331 (2016)

C.C. Kammerer, S. Behdad, L. Zhou, F. Betancor, M. Gonzales, B. Boesl, Y.H. Sohn, Intermetallics 67, 145 (2015)

V.A. Serban, C. Codrean, M. Voda, D. Chicot, X. Decoopman, Mater. Sci. Eng., A 605, 294 (2014)

A. Deschamps, A. Bigot, F.L. Vet, P. Auger, Y. Brechet, D. Blavette, Philos. Mag. A 81, 2391 (2001)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Nos. 51525101 and 51371046), the Program for New Century Excellent Talents in University (No. NECT-12-0109) and the Fundamental Research Funds for the Central Universities (Nos. N130510002, N141008001).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Available online at http://link.springer.com/journal/40195.

Rights and permissions

About this article

Cite this article

Wang, LQ., Ren, YP., Sun, SN. et al. Microstructure, Mechanical Properties and Fracture Behavior of As-Extruded Zn–Mg Binary Alloys. Acta Metall. Sin. (Engl. Lett.) 30, 931–940 (2017). https://doi.org/10.1007/s40195-017-0585-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-017-0585-4