Abstract

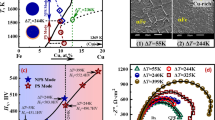

Liquid droplets of three commercial Fe-Ni–based alloys were undercooled to different temperatures by electromagnetic levitation and quenched. Discontinuous changes in the grain size and microstructure as a function of melt undercooling (ΔT) were observed in all three alloys. At ΔT < 80 K, fine, equiaxed grains with a substructure consisting of spherical elements were observed. In the range 80 K < ΔT < 155 K, the microstructure consisted of colonies of columnar dendrites. The colonies were two orders of magnitude larger than the equiaxed grains reported at lower ΔT. At ΔT > 155 K, the equiaxed grains with a substructure of spherical elements returned. The critical undercoolings at which the microstructural transitions occur (ΔT * 1 = 80 K and ΔT * 2 = 155 K) show good agreement with those for similar binary systems. The results were successfully described by calculating the time needed for breakup of the primary dendrites as a function of ΔT and comparing this to the time during which the sample temperature is above the solidus due to recalescence.

Similar content being viewed by others

References

D.M. Herlach, R.F. Cochrane, I. Egry, H.J. Fecht, A.L. Greer: Int. Mater. Rev., 1993, vol. 38 (6), pp. 273–347

J.L. Walker: Physical Chemistry of Process Metallurgy, Part 2, Interscience, New York, NY, 1961, pp. 845–53

L.A. Tarshis, J.L. Walker, J.W. Rutter: Metall. Trans., 1971, vol. 2, pp. 2589–97

T.Z. Kattamis, M.C. Flemings: Trans. TMS-AIME, 1966, vol. 236, pp. 1523–32

M. Schwarz, A. Karma, K. Eckler, D.M. Herlach: Phys. Rev. Lett., 1994, vol. 73 (10), pp. 1380–83

D.M. Herlach, K. Eckler, A. Karma, M. Schwarz: Mater. Sci. Eng. A, 2001, vols. 304–306, pp. 20–25

Y.Z. Chen, G.C. Yang, F. Liu, N. Liu, H. Xie, Y.H. Zhou: J. Cryst. Growth, 2005, vol. 282, pp. 490–97

N. Liu, F. Liu, G. Yang, Y. Chen, D. Chen, C. Yang, Y. Zhau: Physica B, 2007, vol. 387, pp. 151–55

P.K. Galenko, G. Phanikumar, O. Funke, L. Chernova, S. Reutzel, M. Kolbe, D.M. Herlach: Mater. Sci. Eng. A, 2007, vols. 449–451, pp. 649–53

K.F. Kobayashi, P.H. Shingu: J. Mater. Sci., 1988, vol. 23, pp. 2157–66

L. Feng, Y. Gencang, G. Xuefeng: Mater. Sci. Eng. A, 2001, vol. 311, pp. 54–63

D.M. Herlach, P. Galenko, and D. Holland-Moritz: in Metastable Solids from Undercooled Melts, Pergamon Materials Series, R. Cahn, ed., Elsevier, Amsterdam, 2007

A. Karma: Int. J. Non-Equil. Proc., 1998, vol. 11 (2), pp. 201–33

K.A. Jackson, J.D. Hunt, D.R. Uhlmann, T.P. Seward: Trans. TMS-AIME, 1966, vol. 236, pp. 149–58

M. Schwarz: Ph.D. Thesis, Ruhr Universität Bochum, Germany, 1998

P.K. Galenko, D.A. Danilov: Phys. Lett. A, 1997, vol. 325 (3), pp. 271–80

Pernifer36, Material Data Sheet No. 7001, Mar. 2004 ed., ThyssenKrupp VDM GmbH

Magnifer50, Material Data Sheet No. 9002, Aug. 2002 ed., ThyssenKrupp VDM GmbH

Magnifer7904, Material Data Sheet No. 9004, Aug. 2000 ed., ThyssenKrupp VDM GmbH

R.F. Cochrane, D.M. Herlach, B. Feuerbacher: Mater. Sci. Eng. A, 1991, vol. 133, pp. 706–10

P.K. Galenko, D.A. Danilov: Phys. Lett. A, 1997, vol. 235 (3), pp. 271–80

P.K. Galenko, D.A. Danilov: J. Cryst. Growth, 1999, vol. 197 (4), pp. 992–1002

E. Brener and D. Temkin: unpublished research, Forschungszentrum Julich, Germany, 1996.

H. Müller-Krumbhaar, T. Abel, E. Brener, M. Hartmann, N. Eissfeldt, D. Temkin: JSME Int. J. B, 2002, vol. 45 (1), pp. 129–32

W. Löser, D.M. Herlach: Metall. Trans. A, 1992, vol. 23A, pp. 1585–91

W. Kurz, D.J. Fisher: Fundamentals of Solidification, 3rd ed., Trans Tech Publications, Aedermannsdorf, Switzerland, 1992, p. 294

A. Gabriel, P. Gustafson, I. Ansara: CALPHAD, 1987, vol. 11 (2), pp. 203–18

Binary Alloy Phase Diagrams, 2nd ed., T.B. Massalski, H. Okamoto, P.R. Subramanian, and L. Kacprzak, eds., ASM INTERNATIONAL, Materials Park, OH, 1992

G. Pottlacher, H. Hosaeus, B. Wilthan, E. Kaschnitz, A. Seifter: Thermochimica Acta, 2002, vol. 382, pp. 255–67

Y. Sato, K. Sugisawa, D. Aoki, T. Yamamura: Meas. Sci. Technol., 2005, vol. 16, pp. 363–71

Acknowledgments

The authors thank H.-G. Lindenkreuz for performing the quenching experiments, B. Bartusch for the DSC measurements, and Dr. P.K. Galenko (DLR Köln) for helpful discussions. Financial support for this work was provided by the European Space Agency under the MAP, Project No. AO 99-101.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted April 24, 2008.

Appendix I

Appendix I

Calculation Parameters

Parameter (Unit) | P36 | M50 | M79 | Source |

|---|---|---|---|---|

x (at. pct) | Fe-34.85Ni-0.7C | Fe-48.17Ni-0.09C | Fe-84.11Ni-0.1C | |

k Fe-Ni | 0.944 | 0.988 | 0.98 | [27]** |

k Fe-C | 0.174 | 0.205 | 0.205 | [28]** |

m l(Fe-Ni) (K/at. pct) | −1 | −0.15 | 0.65 | [27]** |

m l(Fe-C) (K/at. pct) | −16.9 | −17.8 | −17.8 | [28]** |

T l (K) | 1750 | 1733 | 1727 | DSC* |

T s (K) | 1726 | 1710 | 1702 | DSC* |

ΔH f (J/g) | 304 | 322 | 311 | DSC* |

C pliq at T l (J/g/K) | 0.76 | 0.75 | 0.74 | [27]** |

C psol at RT (J/g/K) | 0.68 | 0.68 | 0.67 | [27]** |

ρ liq at T l (gcm−3) | 7.55 | 7.55 | 7.55 | [29]† |

ρ sol at RT (gcm−3) | 8.1 | 8.25 | 8.7 | |

α liq at T l (m2/s) | 4.92 × 10−6 | 4.88 × 10−6 | 4.86 × 10−6 | [29]† |

η liq at T l (mPas) | 0.75 | 0.74 | 0.71 | [30]** |

D liq (m2/s) | 6 × 10−9 | 6 × 10−9 | 6 × 10−9 | assumed |

V DF (m/s) | 3 | 3 | 3 | assumed |

V D (m/s) | 25 | 25 | 25 | assumed |

d o (m) | 8.52 × 10−10 | 7.84 × 10−10 | 7.89 × 10−10 | calculated |

μ K (ms−1 K−1) | 1.01 | 2.95 | 1.095 | calculated |

ε c (pct) | 2 | 2 | 2 | assumed |

a 1, a 2, σ 0 | 0.3, 0.1, 30 | 0.3, 0.1, 30 | 0.3, 0.1, 30 | assumed |

Rights and permissions

About this article

Cite this article

Woodcock, T., Shuleshova, O., Gehrmann, B. et al. Microstructural Transitions in Commercial Fe-Ni–Based Soft-Magnetic Alloys Quenched from Undercooled Liquid Droplets. Metall Mater Trans A 39, 2906–2913 (2008). https://doi.org/10.1007/s11661-008-9635-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-008-9635-x