Abstract

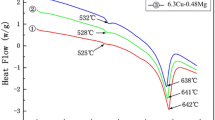

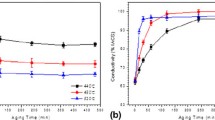

This work explores how the Cu/Mg ratio affects the thermal stability of the extrusion of Al-4.6 pct Cu-Mg-Ag alloys at aerodynamic heating temperatures of up to 155 °C for 1000 hours. The Cu/Mg ratio was modified by adding various amounts of elemental Mg. The alloy microstructures, which determine thermal stability, were analyzed with an optical microscope, an electrical conductivity meter, a differential scanning calorimeter (DSC), and a transmission electron microscope. Experimental results indicate that reducing the Cu/Mg ratio of the alloy by the further addition of Mg causes Ω to become the primary strengthening phase after aging treatment, increasing the hardness and the thermal stability, although the θ′ phase is suppressed. The S phase does not affect the thermal stability of the alloy, because it is present in only a low quantity. Results of this study also demonstrate that the hot-extruded low Cu/Mg alloy satisfies the requirement of the material thermal stability of commercial supersonic aerial applications.

Similar content being viewed by others

Notes

JEOL is a trademark of Japan Electron Optics Ltd., Tokyo.

References

J.E. Hatch: Aluminum Properties and Physical Metallurgy, ASM INTERNATIONAL, Metals Park, OH, 1984, pp. 321–65

I.J. Polmear, G. Pons, Y. Barbaux, H. Octor, C. Sanchez, A.J. Morton, W.E. Borbidge, S. Rogers: Mater. Sci. Technol., 1999, vol. 15, pp. 861–68

S.M. Kazanjian, N. Wang, E.A. Starke Jr.: Mater. Sci. Eng. A, 1997, vols. A234–A236, pp. 571–74

V.A. Phillips: Acta Mater., 1975, vol. 23, pp. 751–67

I.J. Polmear: Trans. TMS-AIME, 1964, vol. 230, pp. 1331–39

J.T. Vietz, I.J. Polmear: J. Inst. Met., 1966, vol. 94, pp. 410–17

R.J. Chester, I.J. Polmear: Metallurgy of Light Alloys, Spring Residential Conf., Institute of Metallurgists, London, 1983, vol. 3 (20), pp. 75–81

K.M. Knowles, W.M. Stobbs: Acta Cryst. B, 1988, B44, pp. 207–27

B.C. Muddle, I.J. Polmear: Acta Mater., 1989, vol. 37, pp. 777–89

K. Hono, N. Sano, S.S. Babu, R. Okano, T. Sakurai: Acta Mater., 1993, vol. 41, pp. 829–38

K. Hono, T. Sakurai, I.J. Polmear: Scripta Metall., 1994, vol. 30, pp. 695–700

S.P. Ringer, K. Hono, I.J. Polmear, T. Sakurai: Acta Mater., 1996, vol. 44, pp. 1883–98

I.J. Polmear, M.J. Couper: Metall. Trans. A, 1988, vol. 19A, pp. 1027–35

S.P. Ringer, W. Yeung, B.C. Muddle, I.J. Polmear: Acta Mater., 1994, vol. 42, pp. 1715–25

L. Del Castillo, E.J. Lavernia: Metall. Mater. Trans. A, 2000, vol. 31A, pp. 287–98

R.J. Chester, I.J. Polmear: Micron, 1980, vol. 11, pp. 311–12

O. Beffort, C. Solenthaler, P.J. Uggowitzer, M.O. Speidel: Mater. Sci. Eng. A, 1995, vol. A191, pp. 121–34

B.M. Gable, G.J. Shiflet, E.A. Starke Jr.: Metall. Mater. Trans. A, 2006, vol. 37A, pp. 1091–1105

S.P. Ringer, W. Yeung, B.C. Muddle, I.J. Polmear: Acta Mater., 1994, vol. 42, pp. 1715–25

C.R. Hutchison, X. Fan, S.J. Pennycook, G.J. Shiflet: Acta Mater., 2001, vol. 49, pp. 2827–41

S.P. Ringer, B.C. Muddle, I.J. Polmear: Metall. Mater. Trans. A, 1995, vol. 26A, pp. 1659–71

S. Muraishi, S. Kumai, A. Sato: Mater. Trans., 2004, vol. 45, pp. 2974–80

S. Kalpakjian: Manufacturing Engineering Technology, 3rd ed., Addison-Wesley, Reading, MA, 1995, pp. 417–28

J.R. Davis: ASM Specialty Handbook Aluminum and Aluminum Alloys, ASM INTERNATIONAL, Metals Park, OH, 1994, pp. 89–120

J.R. Davis: ASM Specialty Handbook Aluminum and Aluminum Alloys, ASM INTERNATIONAL, Metals Park, OH, 1993, pp. 706–08

K. Osamura, N. Otsuka, Y. Murakami: Phil. Mag. B, 1982, vol. B45, pp. 583–99

G. Riontino, S. Abis: Phil. Mag. B, 1991, vol. B64, pp. 447–61

R.E. Reed-Hill, R. Abbaschian: Physical Metallurgy Principles, 3rd ed., PWS Publishing, Boston, MA, 1994, p. 521

M.A. Kenawy, M.R. Nagy, M.S. Sakr, M.T. Mostafa: Phys Status Solidi A, 1986, vol. 97, pp. k73–k78

A.J. Hillel: Phil. Mag., 1983, vol. 48, pp. 237–43

S. Hirosawa, T. Sato, J. Yokota, A. Kamio: Mater. Trans. JIM, 1998, vol. 39, pp. 139–46

J.E. Hatch: Aluminum: Properties and Physical Metallurgy, ASM INTERNATIONAL, Metals Park, OH, 1984, p. 177

Q. Li, R.N. Shenoy: Mater. Sci., 1997, vol. 32, pp. 3401–06

S. Abis, P. Mengucci, G. Riontino: Phil. Mag. B, 1993, vol. B67, pp. 465–84

C.H. Chang, S.L. Lee, J.C. Lin, R.R. Jeng: Mater. Trans., 2005, vol. 46, pp. 236–40

V. Radmilovic, G. Thomas, G.J. Shiflet, E.A. Starke Jr.: Scripta Metall., 1989, vol. 23, pp. 1141–46

R.E. Reed-Hill, R. Abbaschian: Physical Metallurgy Principles, 3rd ed., PWS Publishing Co., Boston, MA, 1991, pp. 272–88

M. Takeda, Y. Maeda, A. Yoshida, K. Yabuta, S. Konuma, T. Endo: Scripta Mater., 1999, vol. 41, pp. 643–49

C.H. Chang, S.L. Lee, J.C. Lin, M.S. Yeh, R.R. Jeng: Mater. Chem. Phys., 2005, vol. 91 (2–3), pp. 454–62

Acknowledgments

The authors thank the Material and Electro-optics Research Division of the Chung-Sheng Institute of Science and Technology, Taiwan, Republic of China, for financially supporting this research under Contract No. NSC 92-2623-7-008-002. The authors also thank Mr. Yue Te Chen for his enthusiastic assistance with the experiment.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted October 21, 2006.

Rights and permissions

About this article

Cite this article

Chang, CH., Lee, SL., Hsu, TY. et al. Impact of Cu/Mg Ratio on Thermal Stability of Hot Extrusion of Al-4.6 Pct Cu-Mg-Ag Alloys. Metall Mater Trans A 38, 2832–2842 (2007). https://doi.org/10.1007/s11661-007-9332-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-007-9332-1