Abstract

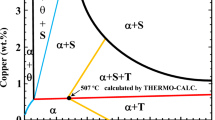

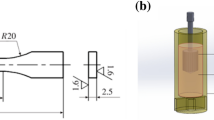

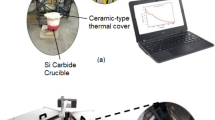

The present study focused on the effect of thermal exposure on the phase evolution and properties of the cast-T6 Al-12Si-4Cu-2Ni-0.8Mg-xGd (x = 0, 0.1, and 0.2) alloy used for cast piston.The thermal stability of the alloys was studied in the temperature range of 200-300 °C for exposure duration up to 500 h, thus obtaining the relationship between the microstructural evolution and its impact on the mechanical properties. The fine Al2Cu phase grew into the coarse θ-Al2Cu phases during the thermal exposure, resulting in a decrease in the mechanical strength of the alloy. The thermal stability and stiffness of the Al-Si-Cu-Ni-Mg alloys were improved with the increase in Gd content from 0 to 0.2%.

Similar content being viewed by others

References

P. Srirangam, S. Chattopadhyay, A. Bhattacharya, S. Nag, J. Kaduk, S. Shankar, R. Banerjee, and T. Shibata, Probing the Local Atomic Structure of Sr-Modified Al-Si Alloys, Acta Mater., 2014, 65, p 185–193

J.H. Chen, E. Costan, M.A. van Huis, Q. Xu, and H.W. Zandbergen, Atomic Pillar-Based Nanoprecipitates Strengthen AlMgSi Alloys, Science, 2006, 312, p 416–419

A. Bjurenstedt, D. Casari, S. Seifeddine, R.H. Mathiesen, and A.K. Dahle, In-Situ Study of Morphology and Growth of Primary α-Al(FeMnCr)Si Intermetallics in an Al-Si Alloy, Acta Mater., 2017, 130, p 1–9

Y. Birol, Melt Treatment of Al-Si Foundry Alloys with B and Sr Additions, J. Mater. Sci., 2017, 52, p 6856–6865

A. Bjurenstedt, S. Seifeddine, and A.E.W. Jarfors, The Effects of Fe-Particles on the Tensile Properties of Al-Si-Cu Alloys, Metals, 2016, 6, p 314–329

A. Morozova, A. Mogucheva, D. Bukin, O. Lukuanova, N. Korotkova, N. Belov, and R. Kaibyshev, Effect of Si and Zr on the Microstructure and Properties of Al-Fe-Si-Zr Alloys, Metals, 2017, 7, p 495–507

G. Rajaram, S. Kumaran, and T.S. Rao, Effect of Graphite and Transition Elements (Cu, Ni) on High Temperature Tensile Behaviour of Al-Si Alloys, Mater. Chem. Phys., 2011, 128, p 62–69

Z. Asghar, G. Requena, H.P. Degischer, and P. Cloetens, Three-Dimensional Study of Ni Aluminides in an AlSi12 Alloy by Means of Light Optical and Synchrotron Microtomography, Acta Mater., 2009, 57, p 4125–4132

M. Zeren, The Effect of Heat-Treatment on Aluminum-Based Piston Alloys, Mater. Des., 2007, 28, p 2511–2517

Y. Sui, D. Ji, L. Han, and Q. Wang, Characterization of the Aging Precipitates of Al-12Si-4Cu-2Ni-0.8Mg-0.2Gd Pistion Alloy, JOM, 2018, https://doi.org/10.1007/s11837-018-3080-0

M. Zhu, Z. Jian, L. Yao, C. Liu, G. Yang, and Y. Zhou, Effect of Mischmetal Modification Treatment on the Microstructure, Tensile Properties, and Fracture Behavior of Al-7.0%Si-0.3%Mg Foundry Aluminum Alloys, J. Mater. Sci., 2010, 46, p 2685–2694

W. Kasprzak, B.S. Amirkhiz, and M. Niewczas, Structure and Properties of Cast Al-Si Based Alloy with Zr-V-Ti Additions and Its Evaluation of High Temperature Performance, J. Alloy. Compd., 2014, 595, p 67–79

J.B. Ferguson, H.F. Lopez, K. Cho, and C.-S. Kim, Temperature Effects on the Tensile Properties of Precipitation-Hardened Al-Mg-Cu-Si Alloys, Metals, 2016, 6, p 43–55

Y. Zhou, Z. Liu, S. Bai, P. Ying, and L. Lin, Effect of Ag Additions on the Lengthening Rate of Ω Plates and Formation of σ Phase in Al-Cu-Mg Alloys During Thermal Exposure, Mater. Charact., 2017, 123, p 1–8

O.R. Myhr, Ø. Grong, and S.J. Andersen, Modelling of the Age Hardening Behaviour of Al-Mg-Si Alloys, Acta Mater., 2001, 49, p 65–75

L. Ceschini, A. Morri, A. Morri, and M.D. Sabatino, Effect of Thermal Exposure on the Residual Hardness and Tensile Properties of the EN AW-2618A Piston Alloy, Mater. Sci. Eng., A, 2015, 639, p 288–297

M. Colombo, E. Gariboldi, and A. Morri, Er Addition to Al-Si-Mg-Based Casting Alloy: Effects on Microstructure, Room and High Temperature Mechanical Properties, J. Alloys Compd., 2017, 708, p 1234–1244

Y. Tzeng, C. Wu, C. Yang, and S. Lee, Effects of Trace Be and Sc Addition on the Thermal Stability of Al-7Si-0.6Mg Alloys, Mater. Sci. Eng., A, 2014, 614, p 54–61

Y. Sui, Q. Wang, T. Liu, B. Ye, H. Jiang, and W. Ding, Influence of Gd Content on Microstructure and Mechanical Properties of Cast Al-12Si-4Cu-2Ni-0.8Mg Alloys, J. Alloys Compd., 2015, 644, p 228–235

ISO 6892-1:2009, Metallic Materials-Tensile Testing-Part 1: Method of Test at Room Temperature, ISO, 2009.

L.R. Garcia, W.R. Osório, and A. Garcia, The Effect of Cooling Rate on the Dendritic Spacing and Morphology of Ag3Sn Intermetallic Particles of a SnAg Solder Alloy, Mater. Des., 2011, 32, p 3008–3012

W.R. Osório, L.C. Peixoto, D.J. Moutinho, L.G. Gomes, I.L. Ferriera, and A. Garcia, Corrosion Resistance of Directionally Solidified Al-6Cu-1Si and Al-8Cu-3Si Alloys Castings, Mater. Des., 2011, 32, p 3832–3837

L.A. Dobrzański, R. Maniara, and J.H. Sokolowski, The Effect of Cooling Rate on Microstructure and Mechanical Properties of AC AlSi9Cu Alloy, Arch. Mater. Sci. Eng., 2007, 28, p 105–112

H.M. Medrano-Prieto, C.G. Garay-Reyes, C.D. Gómez-Esparza, J. Aguilar-Santillán, M.C. Maldonado-Orozco, and R. Martínez-Sánchez, Evolution of Microstructure in Al-Si-Cu System Modified with a Transition Element Addition and Its Effect on Hardness, Mater. Res., 2016, 19, p 59–66

M. Tash, F.H. Samuel, F. Mucciardi, and H.W. Doty, Effect of Metallurgical Parameters on the Hardness and Microstructural Characterization of As-cast and Heat-Treated 356 and 319 Aluminum Alloys, Mater. Sci. Eng., A, 2007, 443, p 185–201

Z. Lai and D. Ye, Effect of Cooling Method and Aging Treatment on the Microstructure and Mechanical Properties of Sn-10Bi Solder Alloy, J. Mater. Sci.: Mater. Electron., 2016, 27, p 1–10

J.X. Jia, A. Atrens, G. Song, and T.H. Muster, Simulation of Galvanic Corrosion of Magnesium Coupled to a Steel Fastener in NaCl Solution, Mater. Corros., 2015, 56, p 468–474

L. Han, Y. Sui, Q. Wang, K. Wang, and Y. Jiang, Effects of Nd on Microstructure and Mechanical Properties of Cast Al-Si-Cu-Ni-Mg Piston Alloys, J. Alloys Compd., 2017, 695, p 1566–1572

H. Li, D. Huang, W. Kang, J. Liu, Y. Ou, and D. Li, Effect of Different Aging Processes on the Microstructure and Mechanical Properties of a Novel Al-Cu-Li Alloy, J. Mater. Sci. Technol., 2016, 32, p 1049–1053

Y. Sun, S. Ma, H. Wang, L. Chen, K. Gao, Y. Ma, and B. Liu, Effects of Complex Modification by Sr-Sb on the Microstructures and Mechanical Properties of Al-18 wt.% Mg2Si-4.5Cu Alloys, Materials, 2016, 9, p 157–165

K. Gao, S. Li, L. Xu, and H. Fu, Effect of Sample Size on Intemetallic Al2Cu Microstructure and Orientation Evolution During Directional Solidification, J. Cryst. Growth, 2014, 394, p 89–96

H. Rudinato, S. Yang, K.W. Nam, and Y.J. Kim, Mechanical Properties of Al-14Si-2.5Cu-0.5 Mg Aluminum-Silicon P/M Alloy, Rev. Adv. Mater. Sci., 2011, 28, p 145–149

D.J. Chakrabarti and D.E. Laughlin, Phase Relations and Precipitation in Al-Mg-Si Alloys with Cu Additions, Prog. Mater Sci., 2004, 49, p 389–410

A. Biswas, D.J. Siegel, and D.N. Seidman, Compositional Evolution of Q-Phase Precipitates in an Aluminum Alloy, Acta Mater., 2014, 75, p 322–336

C.-Y. Jeong, High Temperature Mechanical Properties of Al-Si-Mg-(Cu) Alloys for Automotive Cylinder Heads, Mater. Trans., 2013, 54, p 588–594

J.F. Nie and B.C. Muddle, Comments on the “Dislocation Interaction with Semicoherent Precipitates (Ω Phase) in Deformed Al-Cu-Mg-Ag Alloy”, Scr. Mater., 2000, 42, p 409–413

G. Liu, G.J. Zhang, X.D. Ding, J. Sun, and K.H. Chen, Modeling the Strengthening Response to Aging Process of Heat-Treatable Aluminum Alloys Containing Plate/Disc- or Rod/Needle-Shaped Precipitates, Mater. Sci. Eng., A, 2003, 344, p 113–124

C. Wagner, Theorie der Alterung von Niederschlägen durch Umlösen (Ostwald-Reifung), Zeitschrift für Elektrochemie, Berichte der Bunsengesellschaft für physikalische Chemie, 1961, 65, p 581–591

I.M. Lifshitz and S.V. Vitaly, The Kinetics of Precipitation from Supersaturated Solid Solutions, J. Phys. Chem. Solids, 1961, 19, p 35–50

S. Esmaeili, D. Lloyd, and W. Poole, A Yield Strength Model for the Al-Mg-Si-Cu Alloy AA6111, Acta Mater., 2003, 51, p 2243–2257

J.E. Tibballs, J.A. Horst, and C.J. Simensen, Precipitation of α-Al(Fe, Mn)Si from the Melt, J. Mater. Sci., 2001, 36, p 937–941

K.L. Fan, G.Q. He, X.S. Liu, M. She, Y.L. Yuan, Y. Yang, and Q. Lu, Tensile and Fatigue Properties of Gravity Casting Aluminum Alloys for Engine Cylinder Heads, Mater. Sci. Eng., A, 2013, 586, p 78–85

Acknowledgments

This project funded by the National Natural Science Foundation of China (No. 51802134), China Postdoctoral Science Foundation (No. 2018T110999), Yunnan Provincial Department of Education Science Research Fund Project (No. 2018JS033), and Yunnan Postdoctoral Science Foundation.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Sui, Y., Han, L. & Wang, Q. Effects of Thermal Exposure on the Microstructure and Mechanical Properties of Al-Si-Cu-Ni-Mg-Gd Alloy. J. of Materi Eng and Perform 28, 908–915 (2019). https://doi.org/10.1007/s11665-018-3835-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3835-3