Abstract

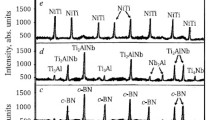

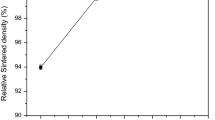

Due to their excellent shape memory and superelasticity properties, NiTi compounds are considered among the most important shape memory alloys. The present work presents a synthesis method for obtaining dense NiTi from elemental powders using a modified spark plasma sintering (SPS) setup characterized by considerably higher current density through the sample at the same total current, as well as drastically decreased heat losses. This provides the possibility to maximize the use of the strong effect of current density on enhanced interdiffusion in metal-metal systems reported in the literature. In addition, the heat loss reduction results in significantly lower total power consumption for synthesis compared to the commonly used SPS setups. The new setup is based on a metallic die/plunger set, combined with a graphite heat generating foil and a thermoelectrical insulation layer. The effect of the processing time on the homogenization of NiTi and the evolution of the intermetallic compounds with time is studied and compared to conventional SPS. Blending for 5 minutes and processing for 30 minutes (with neither preheating, nor postheating, nor quench) were enough to get almost pure dense cubic NiTi (ρ = 6.10 gcm−3, dominant NiTi phase ≈ 97 pct). A small fraction of both Ti and NiTi2, but neither Ni nor Ni3Ti, was detected after 20 minutes of processing. Ni4Ti3 was detected but not quantified.

Similar content being viewed by others

References

I. Mihálcz: Periodica Polytechnica Ser. Mech. Eng., 2001, vol. 45, pp. 75–86

J. Uchil: Pramana-J. Phys., 2002, vol. 58, pp. 1131–39

K. Otsuka, X. Ren: Intermetallics, 1999, vol. 7, pp. 511–28

J.V. Humbeeck: J. Alloys Compd., 2003, vol. 355, pp. 58–64

R. DesRoches, R. Leon, G. Hess, and J. Ocel: Proc. US-China Millenium Symp. on Earthquake, Beijing, China, 2000

C.L. Chu, C.Y. Chung, P.H. Lin, S.D. Wang: Mater. Sci. Eng., A, 2004, vol. 366, pp. 114–19

K. Ho, G.P. Carman, and P. Jardine: SPIE Smart Struct. Conf., 1999, vol. 3675, pp. 252–67 (See http://aml.seas.ucla.edu/research/pubs/index.htm)

A.R Pelton, J. Dicello, and S. Miyazaki: Minimally Invasive Therapy & Allied Technol., 2000, vol. 9, pp. 107–18 (See http://www.nitinol-europe.com/pdfs/nitinolwire.pdf)

Z. Zhang, J. Frenzel, K. Neuking, G. Eggeler: Acta Mater., 2005, vol. 53, pp. 3971–85

D.C. Lagoudas, E.L. Vandygriff: J. Int. Mater. Sys. Struct., 2002, vol. 13, pp. 837–50

J. Mentz, M. Barm, H.P. Buchkremer, D. Stöver: Adv. Eng. Mater., 2006, vol. 8, pp. 247–52

L.E. Penrod: Master’s Thesis, Texas A&M University, College Station, TX, USA, 2003

K. Thangaraj, Y.C. Chen, and K. Salama: Proc. Symp. from the 2000 ASME Int. Mechanical Engineering Congr. Expo, Orlando, FL, Nov. 5–10, 2000, pp. 59–63

B.Y. Tay, C.W. Goh, M.S. Yong, A.M. Soutar, Q. Li, M.H. Myint, Y.W. Gu, C.S. Lim: SIMTech Tech. Rep., 2006, vol. 7, pp. 21–25

B. Yuan, C.Y. Chung, X.P. Zhang, M.Q. Zeng, M. Zhu: Smart Mater. Struct., 2005, vol. 14, pp. S201–S206

Z.A. Munir, U. Anselmi-Tamburini, M. Ohyanagi: J. Mater. Sci., 2006, vol. 41, pp. 763–77

W. Chen, U. Anselmi-Tamburini, J.E. Garay, J.R. Groza, Z.A. Munir: Mater. Sci. Eng., A, 2005, vol. 394, pp. 132–38

J.E. Garay, U. Anselmi-Tamburini, Z.A. Munir: Acta Mater., 2003, vol. 51, pp. 4487–95

N. Bertolino, J. Garay, U. Anselmi-Tamburini, Z.A. Munir: Philos. Mag., 2002, vol. 82, pp. 969–85

J.R. Friedman, J.E. Garay, U. Anselmi-Tamburini, Z.A. Munir: Intermetallics, 2004, vol. 12, pp. 589–97

U. Anselmi-Tamburini, S. Gennari, J.E. Garay, Z.A. Munir: Mater. Sci. Eng., A, 2005, vol. 394, pp. 139–48

C. Uher and L.M. Sander: Phys. Rev. B, 1983, vol. 27, pp. 1326–32

O.A. Grave, Z.A. Maunir: J. Alloys Compd., 2002, vol. 340, pp. 79–87

A.M. Locci, R. Orrù, G. Cao, Z.A. Munir: Intermetallics, 2003, vol. 11, pp. 555–71

G. Skandan, H. Hahn, B.H. Kear, M. Roddy, W.R. Cannon: Mater. Lett., 1994, vol. 20 (5–6), pp. 305–09

S.L. Zhu, X.J. Yang, D.H. Fu, L.Y. Zhang, C.Y. Li, Z.D. Cui: Mater. Sci. Eng., A, 2005, vol. 408, pp. 264–68

V.I. Zel’dovich, N.Y. Frolova, I.V. Khomskaya, E.A. Epanechnikov: J. Phys. IV France, 2003, vol. 112, pp. 773–76

Acknowledgments

This work is partially supported by the Texas Center for Superconductivity at the University of Houston. We also acknowledge the support of Army Research Office Grant No. 46828-MS-ISP and the support of the Texas Institute for Intelligent Bio-Nano Materials and Structures for Aerospace Vehicles, funded by NASA Cooperative Agreement No. NCC- 1-02038.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted January 12, 2007.

Rights and permissions

About this article

Cite this article

Majkic, G., Chennoufi, N., Chen, Y. et al. Synthesis of NiTi by Low Electrothermal Loss Spark Plasma Sintering. Metall Mater Trans A 38, 2523–2530 (2007). https://doi.org/10.1007/s11661-007-9307-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-007-9307-2