Abstract

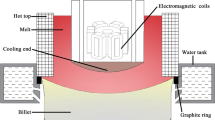

The influence of electromagnetic stirring (EMS) on grain refinement has been studied for two copper-base alloys (Cu-1 wt pct Ni-1 wt pct Pb-0.2 wt pct P and Cu-4 wt pct Zn-4 wt pct Sn-4 wt pct Pb) solidified in a Bridgman furnace. Metallographic inspection of the specimens, temperature measurements during solidification, and numerical simulations performed with CALCOSOFT revealed that the efficiency of EMS is strongly dependent upon the penetration of the liquid in the mushy zone and therefore upon the position of the convection vortices with respect to the liquidus front. In particular, the low-concentration alloy could be grain refined only at high power and when the coil was moved close to the liquidus front. These results were analyzed on the basis of a dendrite fragmentation criterion similar to Flemings’ criterion for local remelting of the mushy zone. Considering that the component of the fluid flow velocity along the thermal gradient, \(u_{l,G} = \frac{{u_e \cdot \nabla T}}{{\left\| {\nabla T} \right\|}}\), must be larger than the casting speed, V c , dendrite fragmentation occurs if

at some depth within the mushy zone where dendrite arms are sufficiently developed, typically 8 λ 2, where λ 2 is the final secondary dendrite arm spacing, K is the permeability of the mushy zone, g l is the volume fraction of liquid, μ is the dynamic viscosity, B 0 is the magnetic field, μ 0 is the permeability of vacuum, and d ind is the distance between the inductor and the liquidus front.

Similar content being viewed by others

References

J. Campbell: Castings, Butterworth Heinemann, Oxford, United Kingdom, 1991.

K. Nakano: Continuous Casting of Copper and Copper Alloys, Shieffield, United Kingdom, 1987, p. 413.

B. Hu and H. Li: Mater. Processing Technol., 1998, vol. 74, p. 56.

A.K. Dahle and L. Arnberg: Acta Mater., 1997, vol. 45, p. 547.

R. Trivedi and W. Kurz: Int. Mater. Rev., 1994, vol. 39, p. 49.

J.D. Hunt: Mater. Sci. Eng., 1984, vol. 65, p. 75.

C. Vivès: Metall. Trans. B, 1989, vol. 20B, p. 623.

C.J. Paradies, R.N. Smith, and M.E. Glicksman: Metall. Mater. Trans. A, 1997, vol. 28A, pp. 875–83.

A. Hellawell, S. Liu, and S.Z. Lu: JOM, 1997, Mar., p. 18.

Y. Fautrelle: Fluid Flows Induced by Alternating Magnetic Fields, Kluwer Academic Publishers, IUATM Symposium, Riga, Latvia, 1989.

S.N. Tewari, R. Shah, and H. Song: Metall. Mater. Trans. A, 1994, vol. 25A, p. 1535.

T. Sato, W. Kurz, and K. Ikawa: Trans. Jpn. Inst. Met., 1987, vol. 28, p. 1012.

K.A. Jackson, J.D. Hunt, D.R. Uhlmann, and T.P. Seward: Trans. Met. Soc. AIME, 1966, vol. 236, p. 149.

S. Liu, S.-Z. Lu, and A. Hellawell: J. Cryst. Growth, 2002, vol. 234, p. 740.

B. Appolaire, V. Albert, H. Combeau, and G. Lesoult: Acta Mater., 1998, vol. 46, p. 5851.

Q. Li and C. Beckermann: J. Cryst. Growth, 2002, vol. 236, p. 432.

G.M. Meseha: Wire J. Int., 1997, vol. 60.

M.C. Flemings: Solidification Processing, 1974.

T. Campanella, C. Charbon, and M. Rappaz: Scripta Mater., 2003, vol. 49, p. 1029.

G. Reiter, V. Maronnier, C. Sommitsch, M. Gäumann, W. Schützenhöfer, and R. Schneider: LMPC 2003, Proc. Int. Symp. on Liquid Metal Processing and Casting, 2003.

P. Desnain, F. Durand, Y. Fautrelle, D. Bloch, J.L. Meyer, and J.P. Riquet: Light Metals 1988, The Metallurgical Society, Inc., Warrendale, PA, 1988, p. 487.

M. Rappaz, M. Bellet, and M. Deville: Numerical Modeling in Materials Science and Engineering, Springer-Verlag Berlin, 2003.

D.R. Poirier: Metall. Trans., 1987, vol. 18B, pp. 245–56.

T. Campanella, C. Charbon, and M. Rappaz: EPFL Lausanne, unpublished research, 2003.

R. Moreau: Progr. Cryst. Growth Characterization Mater., 1999, vol. 161.

A. Hellawell, J.R. Sarazin, and R.S. Steube: Phil. Trans. R. Soc. London A, 1993, vol. 345, p. 507.

H. Esaka: Ph.D. Thesis #615, Ecole Polytechnique Fédérale de Lausanne, Lausanne, 1986.

T. Campanella: Ph.D. Thesis #2818, Ecole Polytechnique Fédérale de Lausanne, Lausanne, 2003.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Campanella, T., Charbon, C. & Rappaz, M. Grain refinement induced by electromagnetic stirring: A dendrite fragmentation criterion. Metall Mater Trans A 35, 3201–3210 (2004). https://doi.org/10.1007/s11661-004-0064-1

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-004-0064-1