Abstract

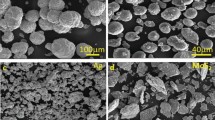

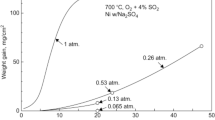

This investigation envisages the performance evaluation of a series of plasma-sprayed coatings from a few inexpensive powders, namely, alumina, plasma dissociated zircon (PDZ), zircon sand, and zircon-20 wt pct calcia. The hardness and adhesion (bond) strength of the coatings have been evaluated. All coatings offer an attractive thermal fatigue property. An added layer of yttria between the top and bond coats improves the thermal fatigue resistance appreciably. The wear performance of these coatings has also been evaluated using a “pin-on-disc” type wear testing setup. The Indian alumina coating offers a superior wear resistance and thermal fatigue property compared to an imported alumina coating. The coatings based on zirconia-silica offer an attractive thermal fatigue resistance along with an acceptable wear resistance. The latter improves considerably upon annealing of the coatings because of the removal of the residual stresses accumulated during deposition. Among these zirconia-silica-based coatings, the zircon-20 wt pct calcia is the most promising. The finishability of these coatings has been studied using a surface grinding setup equipped with a diamond wheel. The cutting forces and the surface roughness of the ground surface have been measured. The coatings have been found to possess a reasonably good grindability.

Similar content being viewed by others

References

K.G. Budinsky: Surface Engineering for Wear Resistance, 1st ed., Prentice-Hall, New York, NY, 1988, pp. 231–34.

M.F.J. Kooloos, G. Van Liempd, and J.M. Houben: Surf. Eng., 1998, vol. 14 (2), pp. 144–48.

H.S. Ahn and O.K. Kwon: Wear, 1993, vols. 162–164, pp. 636–44.

W.W. Dai, C.X. Ding, J.F. Li, Y.F. Zhang, and P.Y. Zhang: Wear, 1996, vol. 196, pp. 238–42.

J.L. Fernandez, R. Rodriguez, Y. Wang, R. Vijande, and A. Rincan: Wear, 1995, vols. 181–183, pp. 417–25.

L. Biandi, A.C. Lager, M. Verdelle, A. Verdelle, and P. Fauchais: Thin Solid Film, 1997, vol. 305, pp. 35–47.

J.W. Vogan, L. Hsu, and R. Stetson: Thin Solid Film, 1981, vol. 84, pp. 75–87.

R.B. Heiman: Plasma Spray Coating, Principle and Application, 1st ed., VCH, Weinheim, Germany, 1996, pp. 201–24.

K.A. Khor and S. Jana: J. Mater. Processing Technol., 1997, vol. 66, pp. 4–8.

T. Kurushima, R. Ishizaki, and R. Haroda: Mater. Manufacturing Processes, 1994, vol. 9 (4), pp. 757–65.

S. Stecura: Thin Solid Film, 1987, vol. 150, pp. 15–40.

R. Sivakumar and M.P. Shrivastava: Oxid. Met., 1983, vol. 20 (3–4), pp. 67–73.

S.V. Joshi and M.P. Shrivastava: Surf. Eng., 1995, vol. 11 (3), pp. 233–39.

P.K.D. Podder and M. Chaudhury: Hanbook of Ceramics, Section A, 1st ed., Kumar and Associates, Calcutta, India, 1999, pp. 247–51.

Y. Wang: Surf. Eng., 1999, vol. 15 (3), pp. 205–09.

T.F.J. Quinn and W.O. Winer: Wear, 1985, vol. 102, pp. 67–80.

Y. Fu, A.W. Batchelor, H. Xing, and Y. Gu: Wear, 1997, vol. 210, pp. 157–64.

L. Zhou, Y.M. Gao, J.E. Zhou, and Q.D. Zhou: Wear, 1994, vol. 176, pp. 39–48.

H. Ono, T. Teramoto, and T. Shinoda: Mater. Manufacturing Processes, 1993, vol. 8 (4–5), pp. 451–63.

D. Chuanxian, H. Bingtang, and L. Huiling: Thin Solid Film, 1984, vol. 118, pp. 485–93.

Y. Wang, Y.S. Lin, and T. Yan: Wear, 1997, vol. 210, pp. 136–44.

I. Inasaki: Ann. CIRP, 1987, vol. 36 (2), pp. 463–71.

S. Malkin: Grinding Technology: Theory and Application of Machining with Abrasives, 1st ed., John Willey & Sons, New York, NY, 1990, pp. 107–11.

M. Huerta and S. Malkin: Trans. ASME, J. Eng. Industry, 1976, vol. pp. 459–67.

M. Huerta and S. Malkin: Trans. ASME, J. Eng. Industry, 1976, vol. pp. 468–73.

D.M. Pai, E. Ratterrnan, and M.C. Shaw: Wear, 1989, vol. 131, pp. 329–39.

B. Zhang and T.D. Howes: Ann. CIRP, 1994, vol. 43 (1), pp. 305–08.

B. Zhang and T.D. Howes: Ann. CIRP, 1995, vol. 44(1), pp. 263–66.

S. Das, P.P. Bandyopadhyay, T.K. Bandyopadhyay, S. Ghosh, and A.B. Chattopadhyay: Metall. Mater. Trans. A, 2003, vol. 34A, pp. 1909–18.

P.P. Bandyopadhyay, S. Das, S. Madhusudan, and A.B. Chattopadhyay: J. Mater. Sci. Lett., 1999, vol. 18, pp. 727–29.

P.P. Bandyopadhyay: Ph.D. Thesis, IIT, Kharagpur, India, 2000.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Das, S., Bandyopadhyay, T.K., Ghosh, S. et al. Processing and characterization of plasma-sprayed ceramic coatings on steel substrate: Part II. On coating performance. Metall Mater Trans A 34, 1919–1930 (2003). https://doi.org/10.1007/s11661-003-0157-2

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-003-0157-2