Abstract

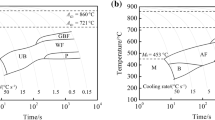

The microstructures and mechanical properties of 550 MPa grade lightweight high strength thin-walled H-beam steel were experimentally studied. The experimental results show that the microstructure of the air-cooled H-beam steel sample is consisted of ferrite, pearlite and a small amount of granular bainites as well as fine and dispersive V(C,N) precipitates. The microstructure of the water-cooled steel sample is consisted of ferrite and bainite as well as a small amount of fine pearlites. The microstructure of the water-cooled sample is finer than that of the air-cooled sample with the average intercept size of the surface grains reaching to 3.5 μm. The finish rolling temperature of the thin-walled high strength H-beam steel is in the range of 750 °C–850 °C. The lower the finish rolling temperature and the faster the cooling rate, the finer the ferrite grains, the volume fraction of bainite is increased through water cooling process. Grain refinement strengthening and precipitation strengthening are used as major strengthening means to develop 550 MPa grade lightweight high strength thinwalled H-beam steel. Vanadium partially soluted in the matrix and contributes to the solution strengthening. The 550 MPa grade high-strength thin-walled H-beam steel could be developed by direct air cooling after hot rolling to fully meet the requirements of the target properties.

Similar content being viewed by others

References

Li DL, You Y, Li H. Design of Automatic Production Line for HF Welding Light Gauge H-beam[J]. Machine Tool — Hydraulics, 2011, 39(20): 1–3

Dong ZH. World H-beam Steels and Rail Production Technology[M]. Beijing: Metallurgical Industry Press, 1999: 56–62

Qian JQ, Shen B, Wu BQ, et al. Development of High-strength Low-Carbon Section Steel[J]. Hot Work. Technol., 2010, 39(8): 62–63

Jiang H, Huang ZY, Yin GQ, et al. Microstructures and Mechanical Properties of High Strength Heavy Section H-beam after Rough Rolling[J]. Shanghai Metals, 2009, 31(3): 40–44

Cheng D, Pan T, Zhang YQ, et al. Study on Microstructure and Mechanical Properties of V-N Microalloyed Heavy Section H Beam and Precipitates in the Steels[J]. Iron Steel Vanadium Titanium, 2008, 29(3): 1–6

Cheng D, Zhang YQ, Yang CF. Application of VN Alloy to High Strength H-Beam Steel[J]. Iron and Steel, 2008, 43(6): 97–100

Yin GQ, Yin YY, Wang SJ, et al. Controlled Rolling Processes and Microstructures of V-N Microalloyed Steels[J]. Heat Treatment of Metals, 2005, 30(11): 43–46

Yu QB, Zhao XP, Sun B, et al. Yield-strength Ratio of Steel Plate for High-rise Building[J]. Iron and Steel, 2007, 42(11): 74–78

Pan GP, Song Q, Yu NL, et al. Quality Control of Exported H Beam under American Standard[J]. Iron and Steel, 2002, 37(8): 33–36

Yang CF, Wang QL. Research, Development, and Production of V-N Microalloyed High Strength Rebars for Building in China[J]. J. Iron and Steel Res. Int., 2008, 15(2): 81–86

Pickering FB. Microalloyed Low Carbon High Strength Steel[M]. Metallurgical Industry Press, Beijing, 1982: 32–36

Huang ZY, Yin GQ, Zheng JP, et al. Microstructures and Mechanical Properties of H-beam Steel after Rough-rolling and Tempering[J]. Heat Treatment, 2009, 24(3): 35–39

Feng JH, Zhang HY, Qian YF, et al. Research on Controlled Cooling of H-beam[J]. Iron Steel Vanadium Titanium, 2003, 24(3): 1–5

Zajac S, Siwecki T, Hutchinson WB, et al. Strengthening Mechanism in Vanadium Microalloyed Steels Intended for Long Products[J]. ISIJ Int., 1998, 38(10): 1 130–1 139

Guo J, Wu D, Zhao XM, et al. Study and Application of Cooling Control after H-Beam Rolling[J]. J.Iron and Steel Res., 2007, 19(5): 40–43

Sun BM, Ji HZ, Yang CF, et al. Precipitation Behavior of Vanadium in V-N Nicroalloyed Steel[J]. Iron and Steel, 2001, 36(2): 44–47

Yin GQ, Huang ZY, Jiang H, et al. Microstructure and Mechanical Properties of High Strength Thick Wall H-beam Steel After Controlled Rolling and Fast Cooling[J]. Heat Treatment of Metals, 2010, 35(5): 69–73

Yang CF, Zhang YQ, Liu SP. Strengthening Mechanism in V-N Microalloyed Reinforcing Bar Steels[J]. Iron and Steel, 2001, 36(5): 55–57

Yin GQ, Huang ZY, Yang CF, et al. Effects of Nitrogen Content and TMCP on Microstructure and Mechanical Properties of V-N Microalloying Steels[J]. Heat Treatment of Metals, 2008, 33(3): 4–8

Wang K, Wang LJ, Cui WF, et al. Effect of V and V-N Microalloying on Deformation-induced Ferrite Transformation in Low Carbon Steels[J]. J. Mater. Sci. Technol., 2006, 22(2): 159–163

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the “11th Five” National Science and Technology Support Project (No. 2006BAE03A13)

Rights and permissions

About this article

Cite this article

Chen, J., Kang, Y., Qian, J. et al. Microstructures and properties of 550 MPa grade high strength thin-walled H-beam steel. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 28, 1217–1222 (2013). https://doi.org/10.1007/s11595-013-0848-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-013-0848-5